Production of press-fit and crimp connections in a vice

A vise, vise technology, applied in the direction of welding/welding connection, connection, conductive connection, etc., can solve the problems of quality loss, damage, crimp connection damage of bonding method, etc., to improve reproducibility and/or quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

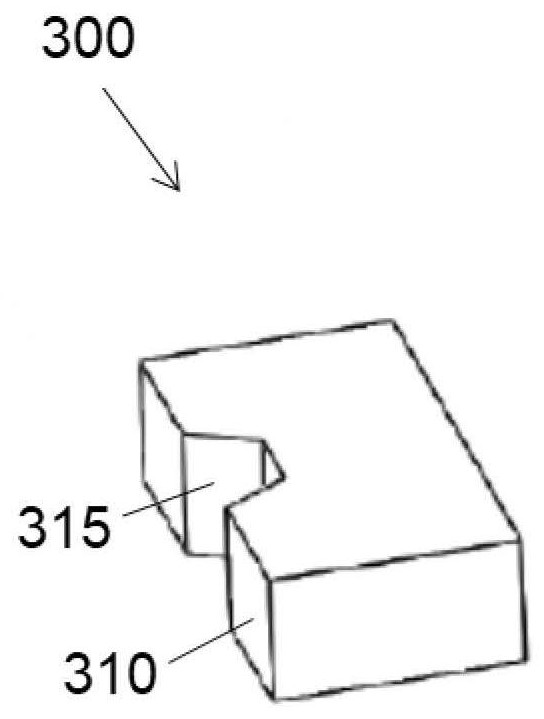

[0035] Figure 1a A schematic view of press insert 300 is shown. It can be clearly seen here that the groove 315 extends along the entire narrow side of the end face 310 of the presser element 300 . This groove 315 is designed here, so that it has a ratio of receiving part 200 ( Figure 1b ) of the groove 215 with a small diameter. Thus, the press insert 300 is suitable for realizing the connection part 150 (see Figure 2a ) deformation. The recess 315 is designed in the embodiment shown so that it has a hexagonal shape when the press inserts 300 are used in pairs.

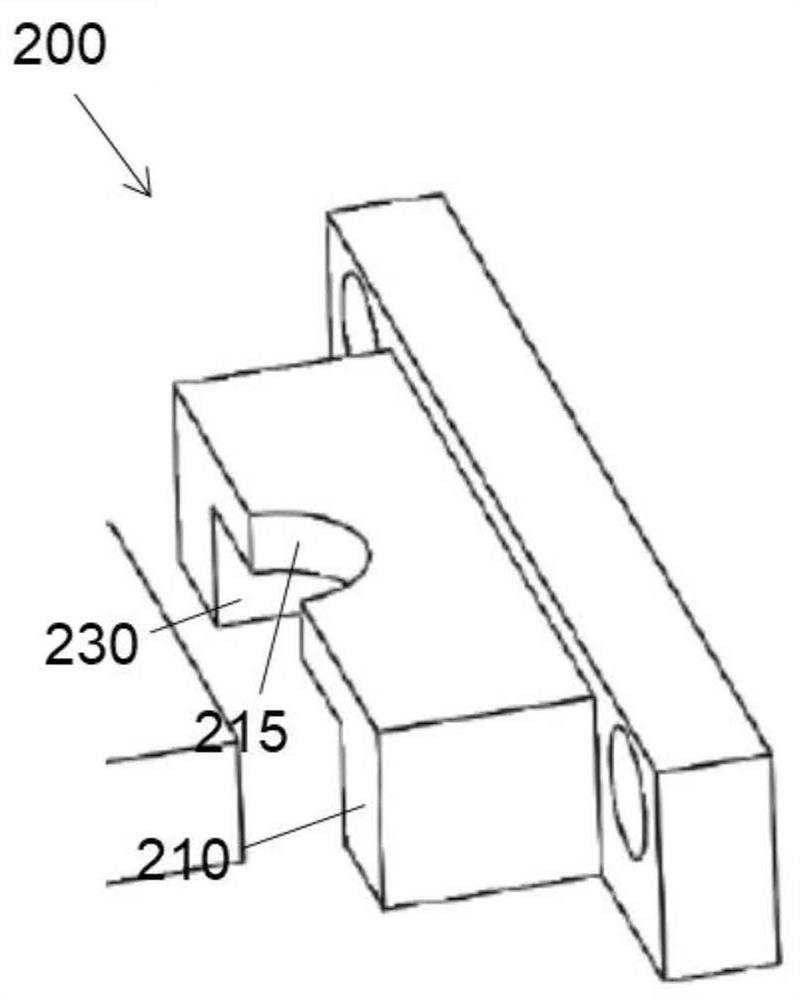

[0036] Figure 1b A schematic view of the receiving part 200 is shown. The receiving part 200 has a recess 215 on the end face 210 . Furthermore, the receiving part 200 has a channel 230 . This channel opens downwards in the embodiment shown. The receiving part 200 is designed so as to act as a press insert 300 (see Figure 1a ) is arranged in the channel 230 , apart from the different diameters and shapes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com