Sand screening device for municipal engineering construction

A kind of engineering and sand screening technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problem of time-consuming and laborious, can not meet the needs of sand screening efficiency, low efficiency of vibrating sand, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

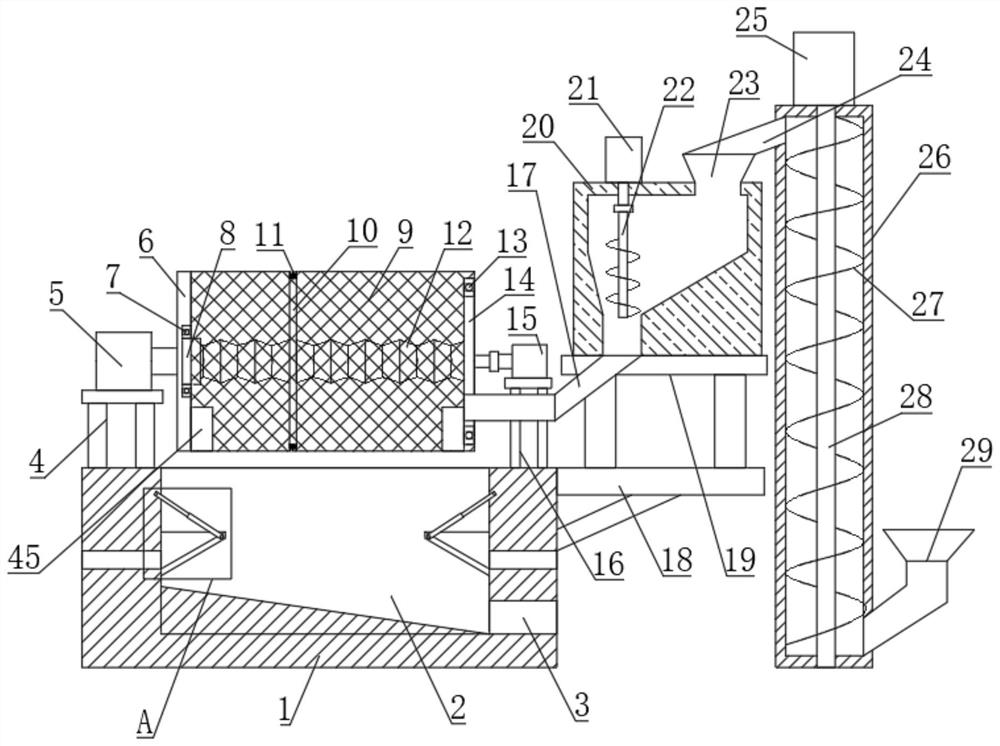

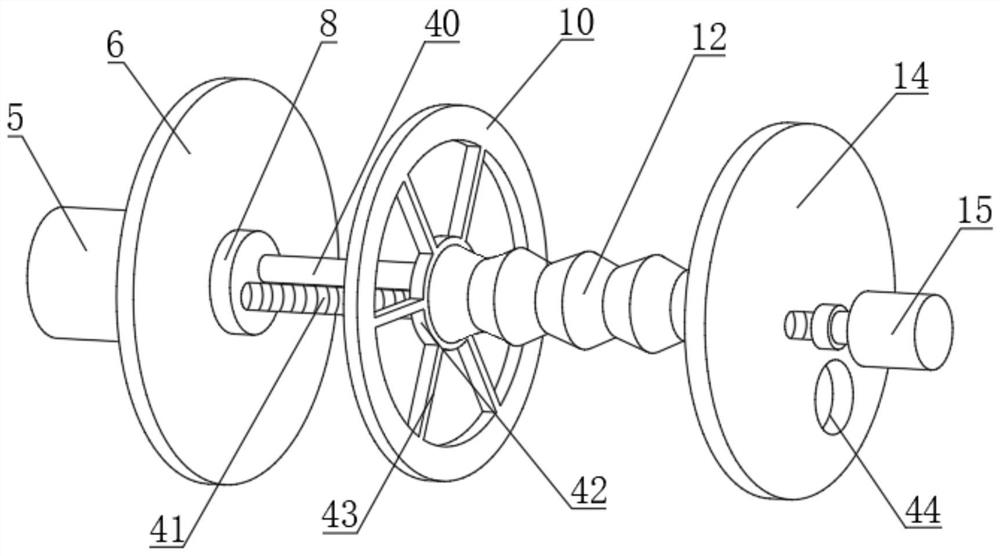

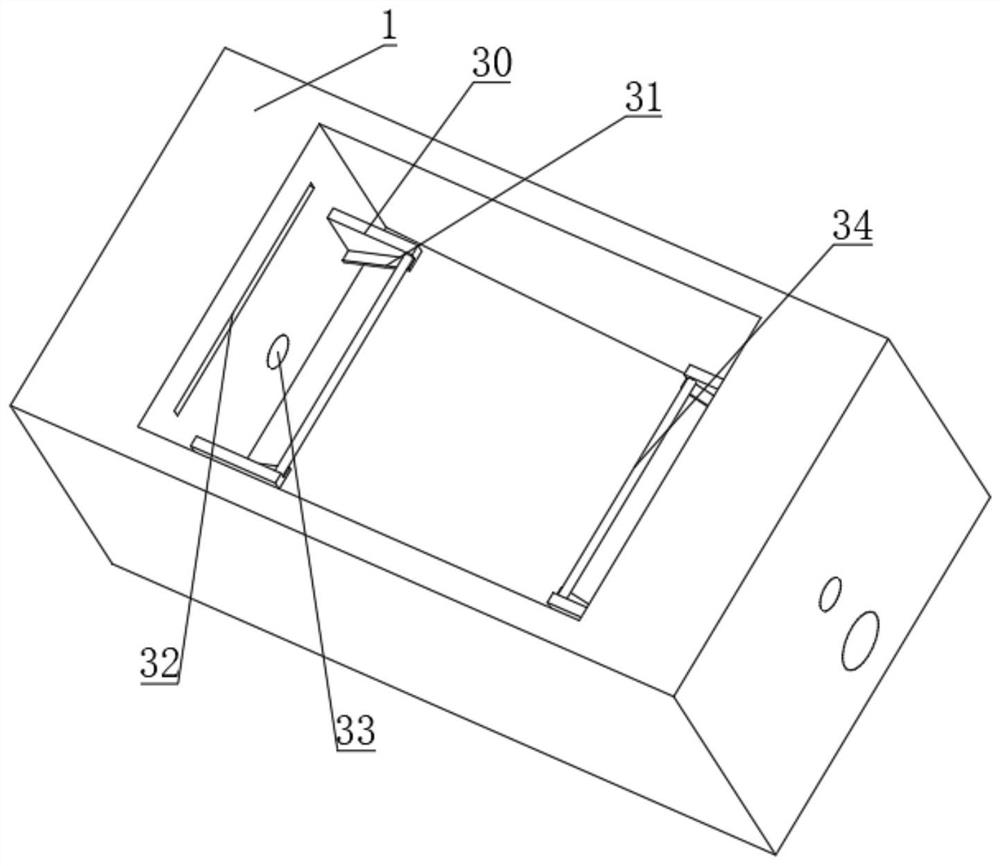

[0025] see figure 1 , figure 2 , image 3 and Figure 4 , a sand screening device for municipal engineering construction, comprising a sand collection tank 1 and a drum 9, the left end of the drum 9 is fixedly connected with a rotating disc 6, and the rotating disc 6 is coaxially fixedly connected with the output shaft of the motor one 5, The right end of cylinder 9 is equipped with bearing two 13, and the inner hole of bearing two 13 is connected with fixed disk 14, and the right end face of rotating disk 6 is equipped with bearing one 7, and the inner hole of bearing one 7 is connected with fixed disk 8, and fixed disk 8 and the fixed disc 14 are provided with a moving plate 42, the moving plate 42 is provided with a threaded through hole and a smooth through hole, the threaded through hole is fitted with a threaded shaft 41, and the smooth through hole is slidably connected with a guide shaft 40 , the two ends of the guide shaft 40 are connected with the fixed disk 8 an...

Embodiment 2

[0031] see figure 1 , figure 2 , image 3 and Figure 4 , this embodiment is a further description of the sand screening device for municipal engineering construction described in Example 1. In this embodiment, a sand storage box 20 is provided on the right side of the drum 9, and the sand storage box 20 A motor 3 21 is installed on the upper surface, the inside of the sand storage box 20 is a sand chamber, the top of the sand chamber is provided with a feeding port 23, the bottom of the sand chamber is connected with a feeding pipe 17, and the feeding pipe 17 communicates with the sand inlet 44 , the top of the feeding pipe 17 is provided with a stirring shaft 22, the upper end of the stirring shaft 22 is connected with the output shaft of the motor three 21, and the stirring shaft 22 is used for stirring the sand to avoid sand agglomeration.

[0032] The right side of described sand storage box 20 is provided with screw conveyor, and screw conveyor is vertically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com