Control method for edge quality of interstitial free (IF) steel and IF steel

A technology with no interstitial atoms and a control method, applied in the control of edge quality, in the field of IF steel, can solve problems such as edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

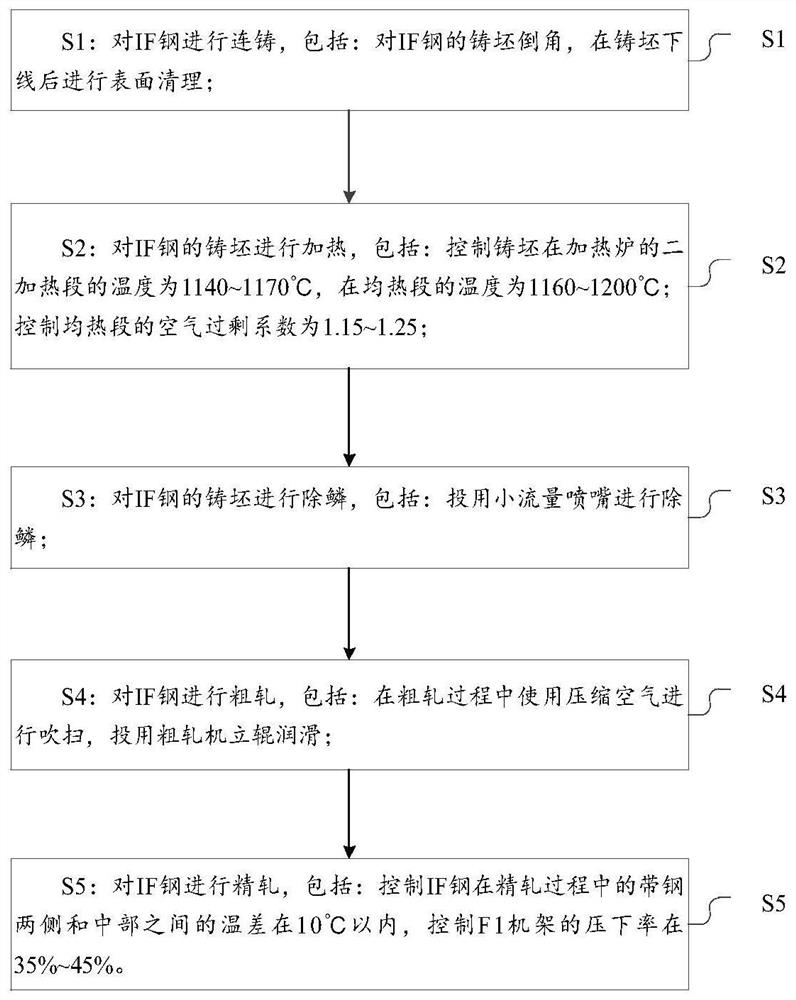

Method used

Image

Examples

Embodiment

[0054] The technical solution of the present invention is applied on the 2250 hot rolling production line of a certain steel factory, and the production data of 1045 coils of IF steel have been tracked, and its control process is as follows:

[0055] 1. Billet quality assurance

[0056] 1) The four corners of the slab are chamfered, and the lengths of the two right-angled sides of the chamfer are 30 and 35 respectively;

[0057] 2) The slab is machine-cleaned off the production line, and the surface layer of the 6 surfaces is removed by 3mm;

[0058] 3) Check the slab after machine cleaning, and the intersection edge is not allowed;

[0059] 4) Check the slab after machine cleaning, and the pinch depth of the crane on the side of the slab should not exceed 3mm;

[0060] 2. Heating process control

[0061] The furnace loading temperature is controlled at 425-636°C, the average furnace loading temperature is 473°C, the actual control range of the secondary heating temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com