Machining equipment for improving strength of aluminum profile and production process

A technology for processing equipment and aluminum profiles, applied in the field of processing and manufacturing, can solve the problems of low degree of mechanization of pipe processing, easy bumping and scratching of operators, and low production efficiency of pipe processing, so as to reduce the cost of manual transportation and improve strength and cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

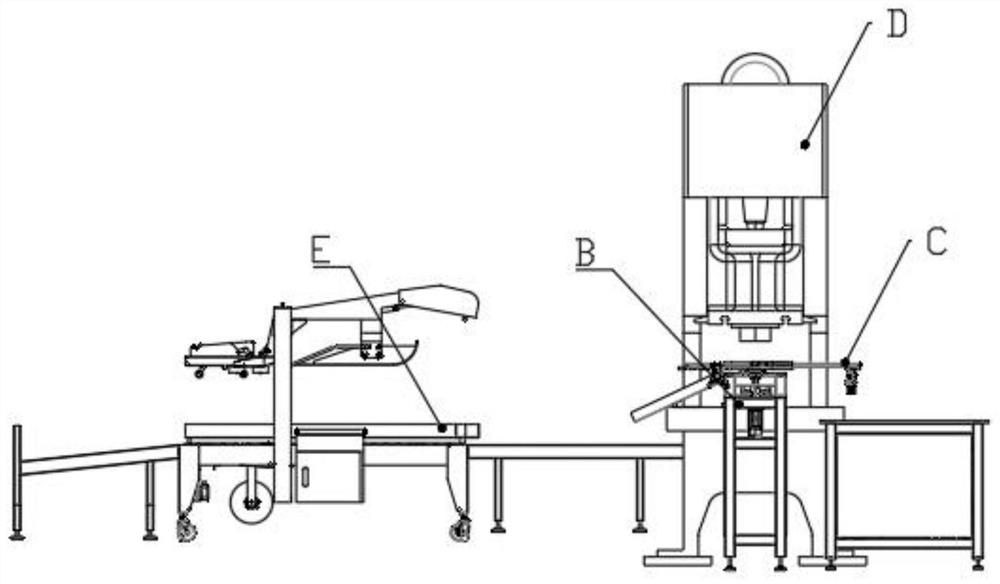

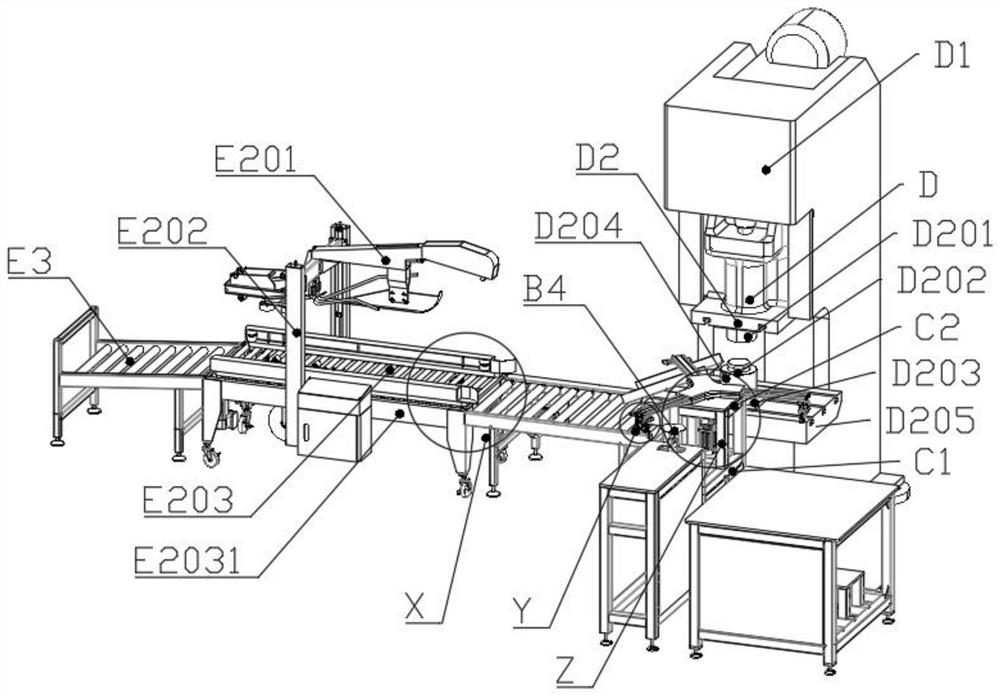

[0058] Such as Figure 1-6 As shown, a processing equipment for improving the strength of aluminum profiles, feeding mechanism B, discharging mechanism C, stamping device D and material transporting mechanism E, feeding mechanism B is set in front of discharging mechanism C, and discharging mechanism C is set in the stamping device In front of D, and the feeding mechanism B, the discharging mechanism C and the punching device D are installed on the same center line, the feeding mechanism E is installed on the left part of the punching device D, and the cost is replaced by the automatic rotation and release of the discharging mechanism C The expensive traditional unloading machine realizes the cost reduction, and at the same time avoids the problem of excessive leakage during the manual operation. The automatic loading function is different from the previous manual loading, which greatly improves the production efficiency and reduces the occurrence of work-related injuries. At ...

Embodiment 2

[0065] This embodiment is carried out on the basis of the foregoing embodiments 1 and 2, and mainly introduces the structure of the discharging mechanism C of the present invention.

[0066] Such as Figure 1-6 As shown, a processing equipment for improving the strength of aluminum profiles, feeding mechanism B, discharging mechanism C, stamping device D and material transporting mechanism E, feeding mechanism B is set in front of discharging mechanism C, and discharging mechanism C is set in the stamping device In front of D, and the feeding mechanism B is installed on the same center line as the discharging mechanism C and the punching device D, and the feeding mechanism E is installed on the left part of the punching device D, through the automatic rotation and release of the discharging mechanism, replacing the high-cost The traditional unloading machine achieves cost reduction and avoids the problem of excessive leakage during the feeding process by manual operation. The ...

Embodiment 3

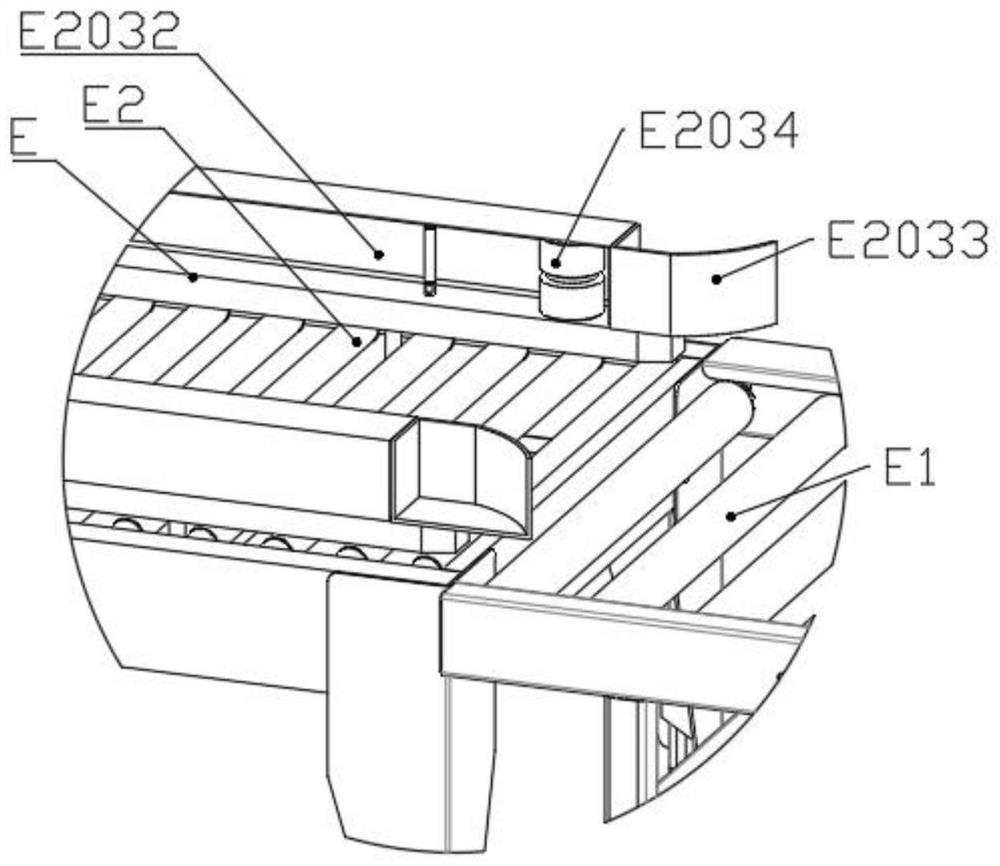

[0079] This embodiment is carried out on the basis of the foregoing embodiments 1 and 2, and mainly introduces the structure of the transport mechanism E of the present invention.

[0080] Such as Figure 1-6 As shown, a processing equipment for improving the strength of aluminum profiles, feeding mechanism B, discharging mechanism C, stamping device D and material transporting mechanism E, feeding mechanism B is set in front of discharging mechanism C, and discharging mechanism C is set in the stamping device In front of D, and the feeding mechanism B, the discharging mechanism C and the punching device D are installed on the same center line, the feeding mechanism E is installed on the left part of the punching device D, and the cost is replaced by the automatic rotation and release of the discharging mechanism C The expensive traditional unloading machine realizes the cost reduction, and at the same time avoids the problem of excessive leakage during the manual operation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com