An electromagnetically driven soft die liquid-filled deep drawing device and process method

A liquid-filled deep drawing and electromagnetic drive technology, which is applied in the field of mechanical processing and devices, can solve the problems of reducing the surface quality and precision of formed parts, low forming efficiency, and small residual stress, and achieve energy control and production automation. The effect of high speed and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

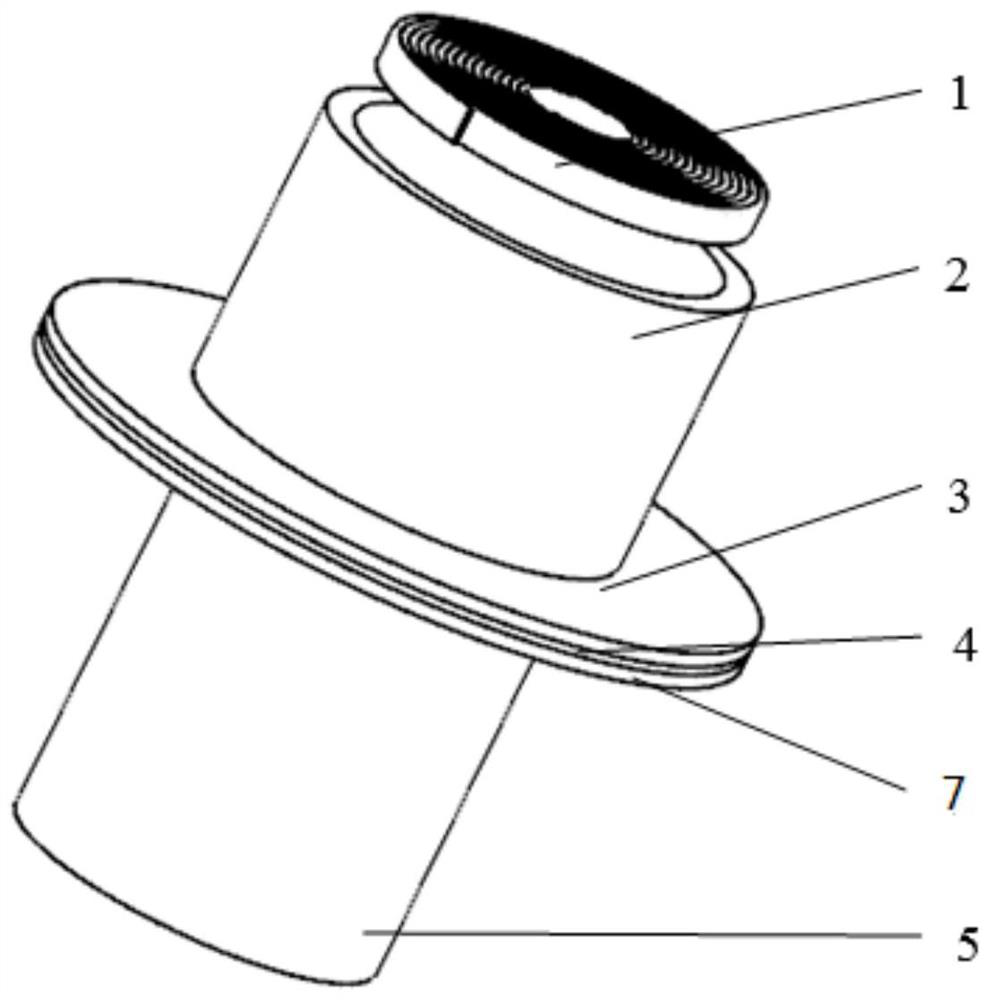

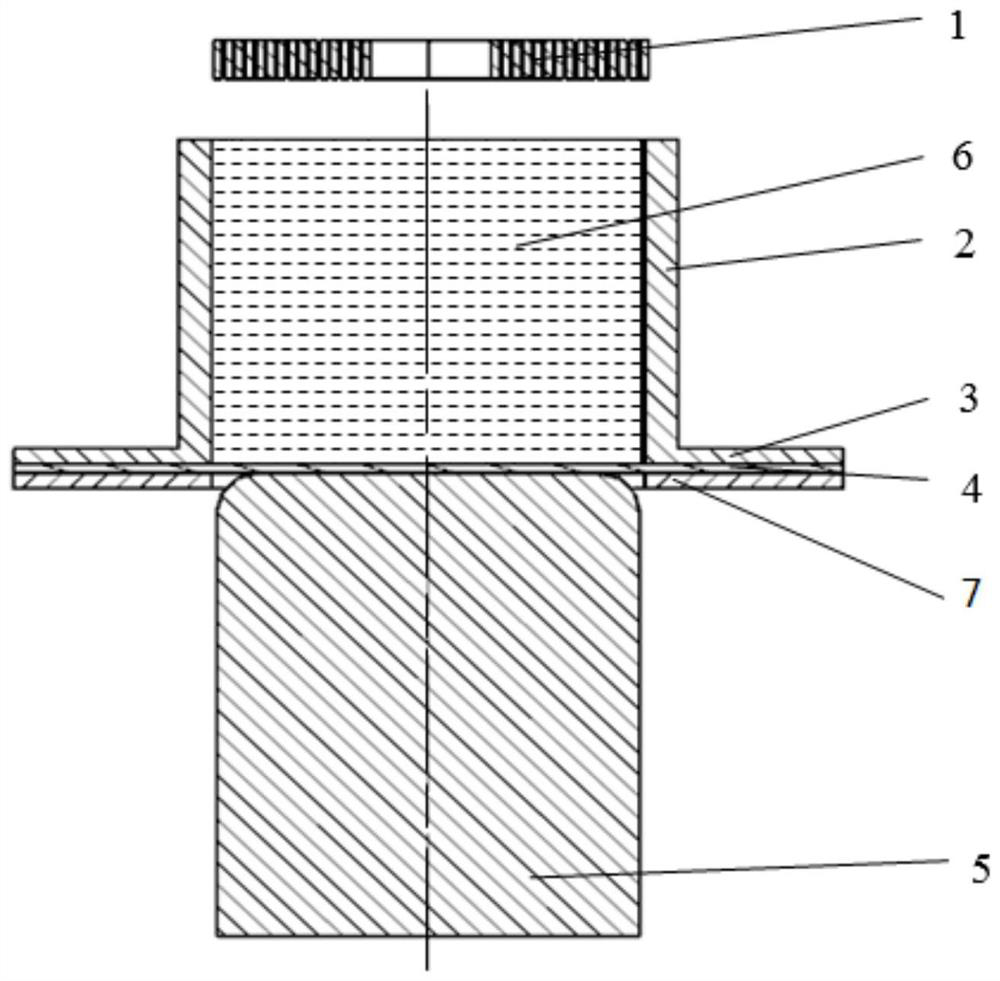

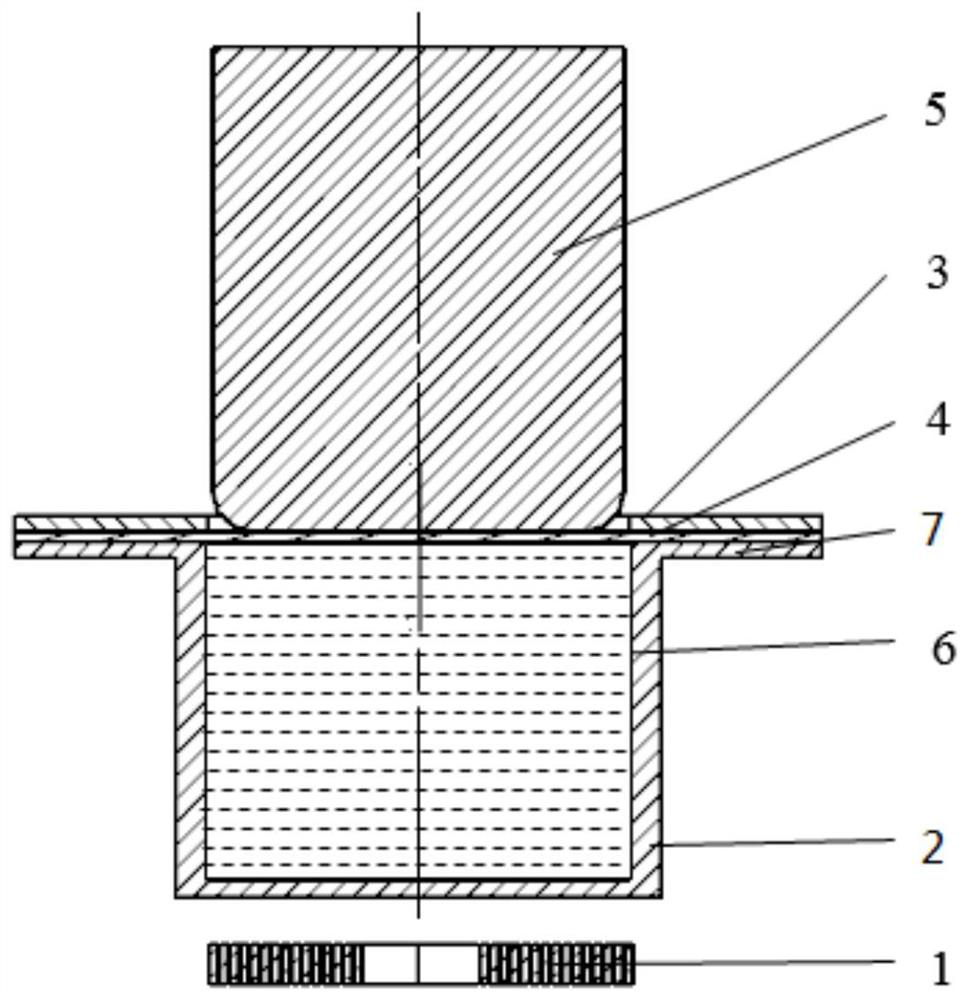

[0040] Embodiment: Take the stretching of a cylindrical piece as an example. Such as figure 2As shown, the initial shape of the plate 4 is circular, the material is DP980, the diameter is 120 mm, and the thickness is 1.2 mm. The outer diameter of the punch 5 is 40mm, and the inner diameter of the hydraulic chamber 2 is 45mm; the plate 4 is placed in the first blankholder 3 and the second blankholder 7, and the magnetic fluid 6 is poured into the hydraulic chamber 2 to give the distance Hydraulic chamber 2 5mm plate coil 1 is supplied with alternating current, while the plate coil 1 is energized, the punch 5 moves upward quickly by 20mm, the plate 4 is pressed against the punch 5 under the pressure of the magnetic fluid 6, and the drawing ratio is 3, and the process is completed. take shape. Compared with the ordinary deep drawing of high-strength steel, the drawing ratio is only 2. In addition, this process reduces springback, improves the forming accuracy of the product, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com