Embossing die and ribbed plate manufacturing method thereof

A manufacturing method and ribbing technology, applied in the field of rib plate manufacturing, can solve the problems of long production cycle and high production cost, and achieve the effect of reducing manufacturing cost, reducing difficulty, and simple and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

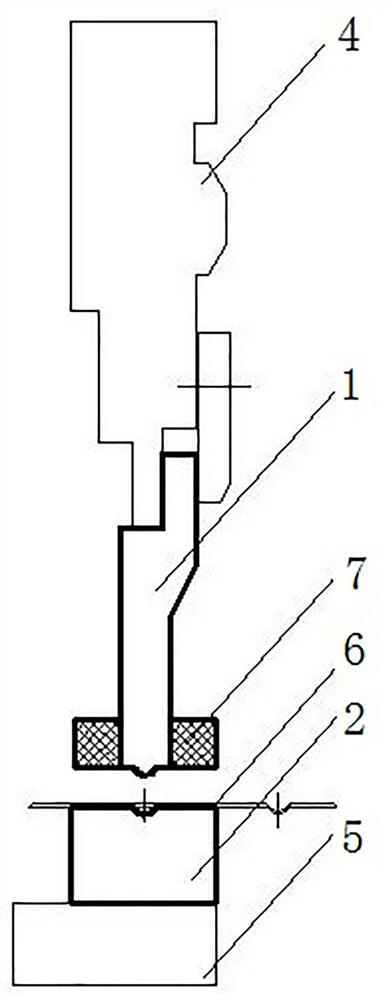

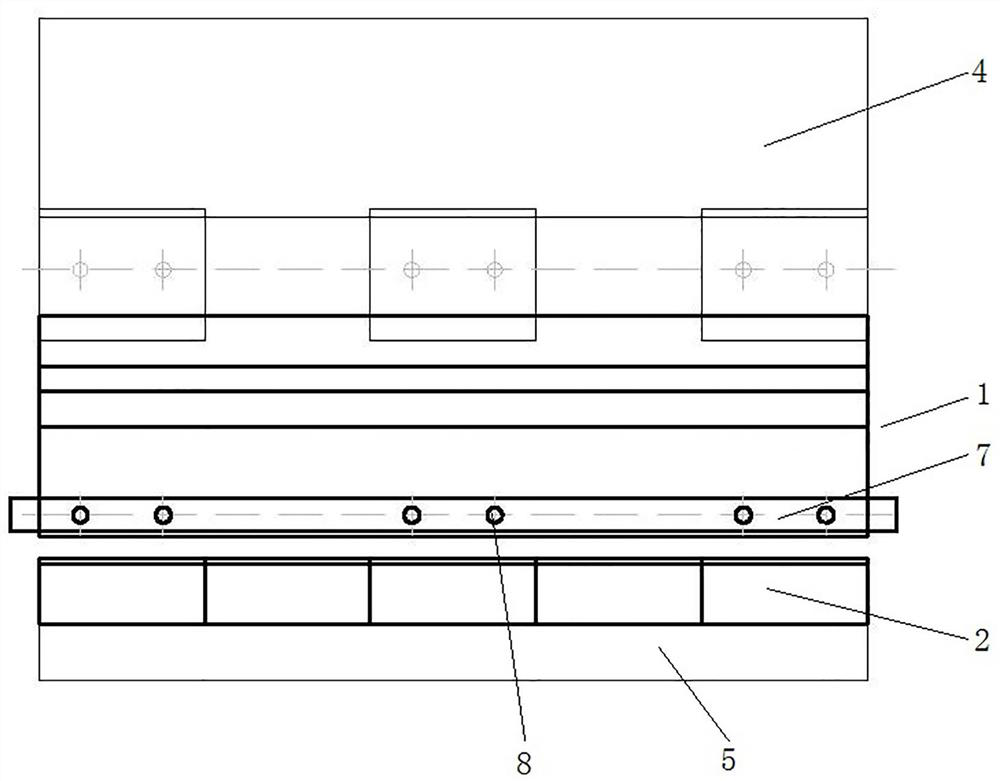

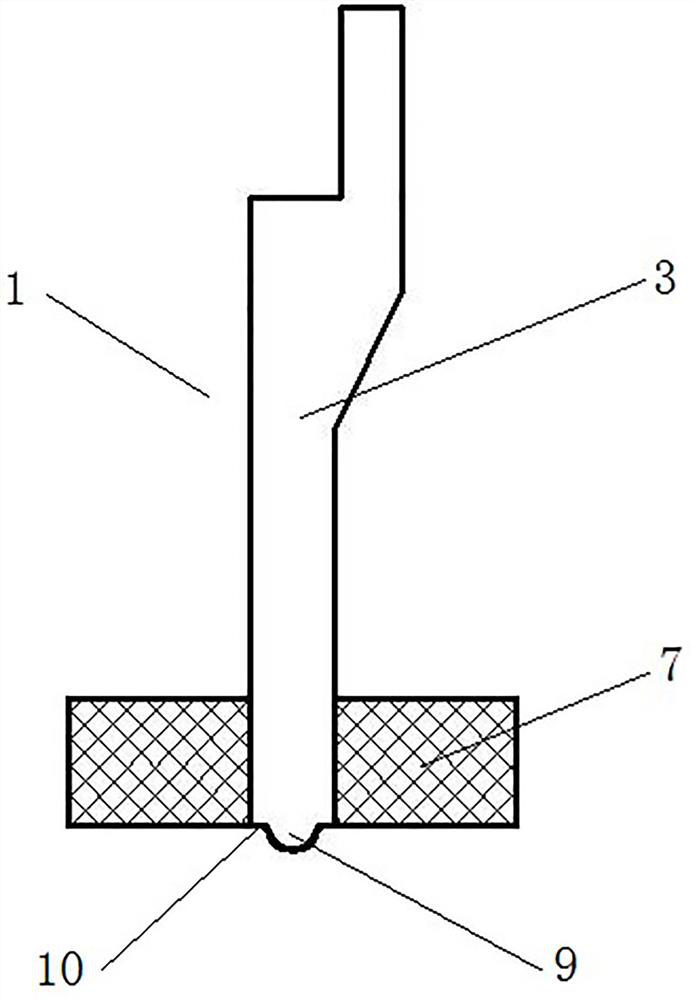

[0031] Embodiment 1 of ribbing die in the present invention, as figure 1 with figure 2 As shown, it includes upper mold 1 and lower mold 2. In this embodiment, the lower mold 2 is a block structure, and its upper surface is processed with a forming groove matching the size of the groove to be formed. The structure of the upper mold 1 is as follows: image 3 As shown, the upper mold 1 is transformed from a bending knife through milling, and includes a bending knife body 3. The upper part of the bending knife body 3 is an installation structure adapted to the upper part 4 of the bending machine, which is used to realize the upper part of the bending machine. Die 1 is installed on the bending machine, and the head part of the bending knife is processed into a punch that matches the lower die 2 by milling.

[0032] When in use, the upper mold 1 is fixed on the upper part 4 of the bending machine, the lower mold 2 is fixed on the lower part 5 of the bending machine, the plate-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com