Finish rolling system for metal powder semi-solid primary rolling strip

A metal powder and semi-solid technology, which is applied in the field of post-processing equipment for pre-rolled strips, can solve the difficulties in controlling the width, thickness and length direction of strips, the chaotic production requirements of strip changes, and the inability to maintain density and mechanical properties. To achieve higher requirements and other issues, to achieve high roll gap adjustment accuracy, improve rolling accuracy, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

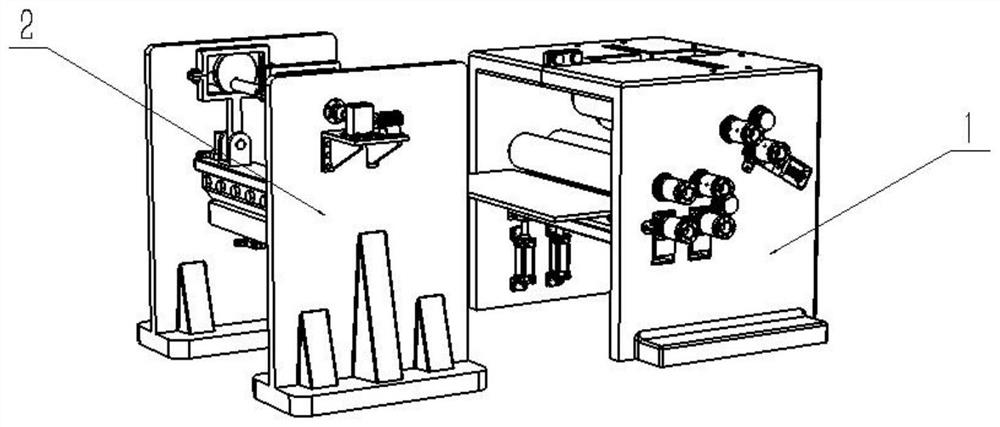

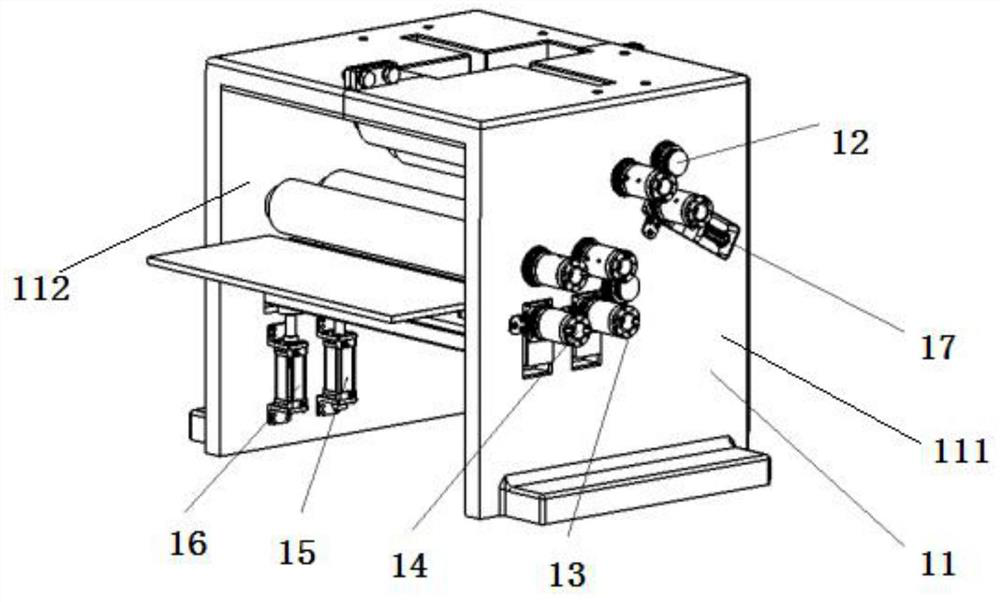

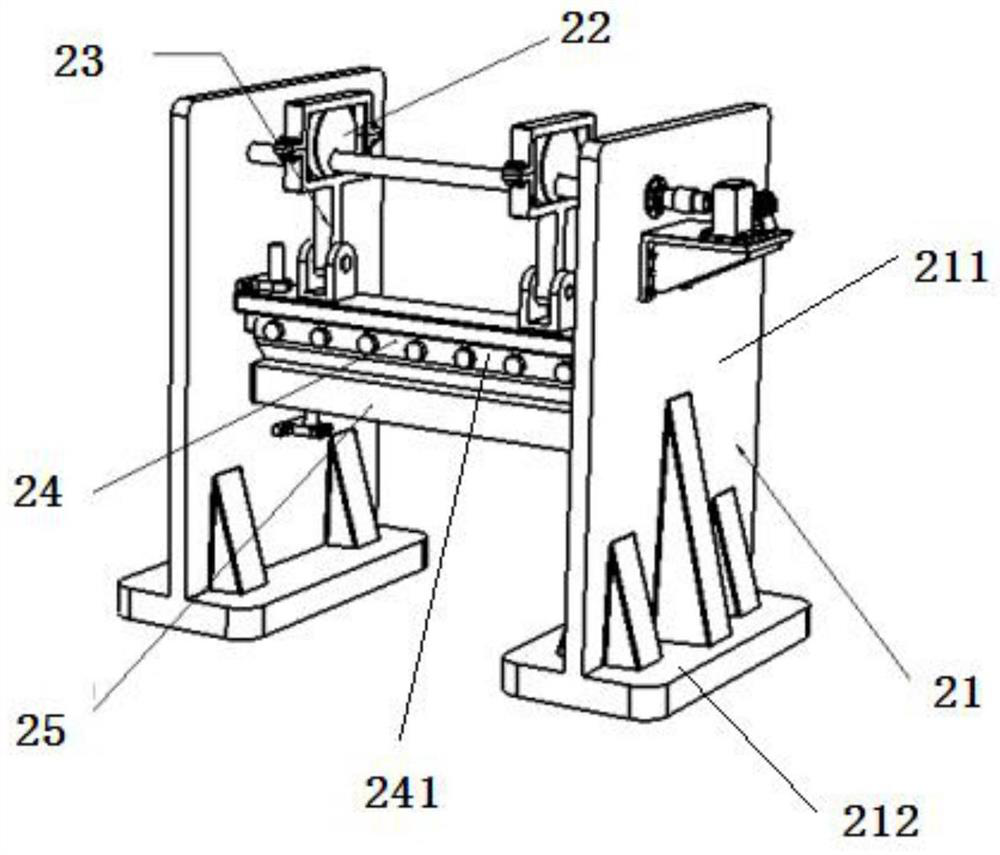

[0028] The present invention provides a finishing rolling system for metal powder semi-solid preliminary rolling strip, such as Figure 1 to Figure 7 As shown, it includes a finishing unit 1 and a shearing unit 2, and the finishing unit 1 includes a finishing stand 11, a first roll system 12, a second roll system 13, a third roll system 14, and a first roll gap adjustment device 17 , the second roll gap adjusting device 15 and the third roll gap adjusting device 16, the shearing unit 2 includes a shearing frame 21, an eccentric cam 22, a cam connecting rod 23, a reciprocating shear knife 24 and a liftable strip support plate 25.

[0029]The finishing stand 11 comprises a first finishing stand 111 and a second finishing stand 112, the first finishing stand 111 and the second finishing stand 112 are connected by means of three boss structures at the splicing place, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com