Conveyor for ore transportation

A conveyor and conveying mechanism technology, applied in conveyor objects, transportation and packaging, rollers, etc., can solve the problems of increasing safety hazards, high labor intensity, high labor and material costs, preventing side leakage and improving transportation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

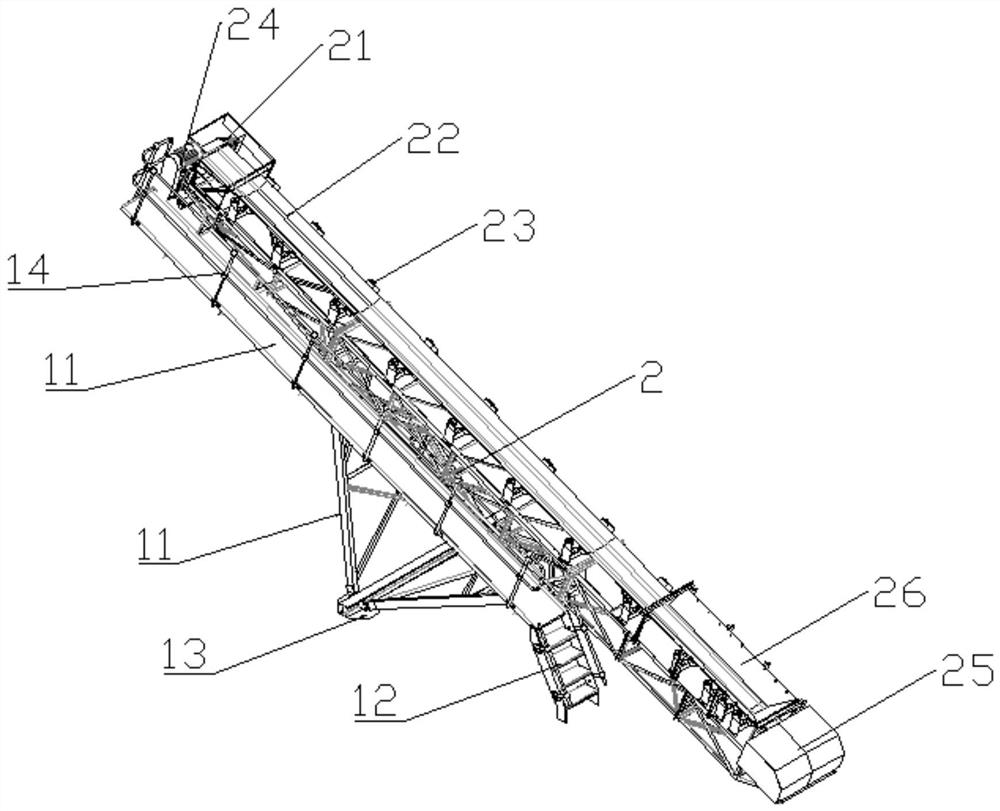

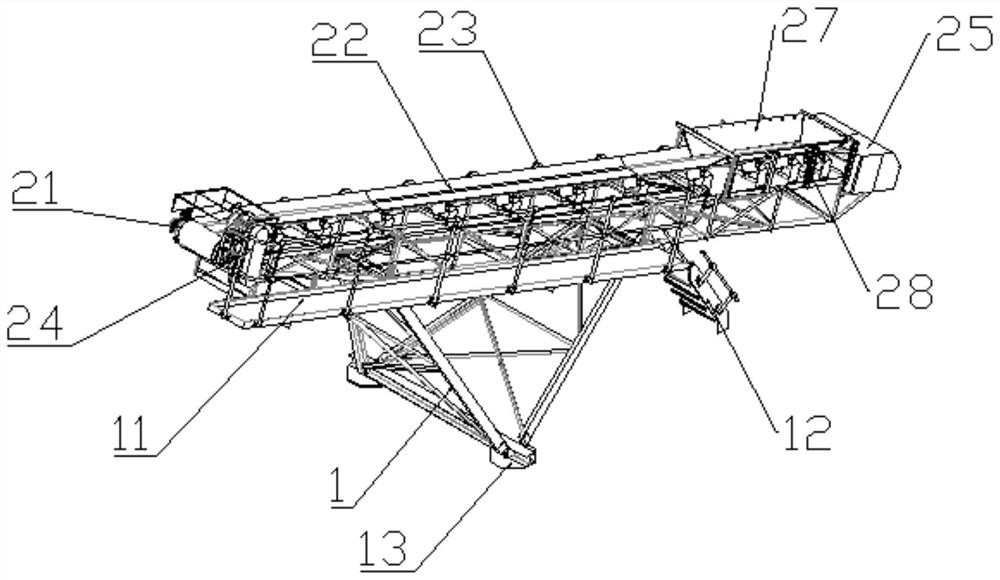

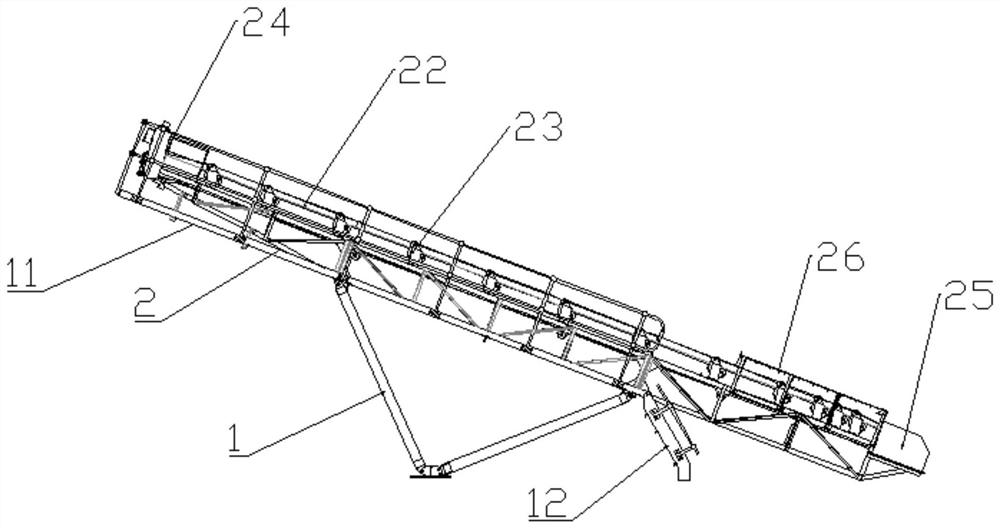

[0015] Such as Figure 1~3 as shown,

[0016] This embodiment provides a conveyor for ore transportation, including a frame 1 and a conveying mechanism installed on the frame 1, the frame 1 is installed in the middle of the conveying mechanism, and the conveying mechanism is inclined through the frame 1 Set, the conveying mechanism includes a frame 2, a driving roller 21 and a driven roller installed at both ends of the frame 2, a conveyor belt 22 sleeved on the driving roller 21 and the driven roller, and the driving roller 21 and the driven roller The rollers are installed on the corresponding bearings of the frame 2 respectively, and several groups of conveying rollers 23 are distributed on the corresponding conveyor belt 22 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com