Wallboard-spliced and foundation-damped assembly type frame structure

A frame structure and prefabricated technology, applied in the direction of walls, anti-seismic, building components, etc., can solve the problems of building structure damage, limited anti-seismic function, ignoring the anti-seismic structure of the foundation of the house, etc., to improve the anti-seismic performance, increase the scope of application, and enhance the strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

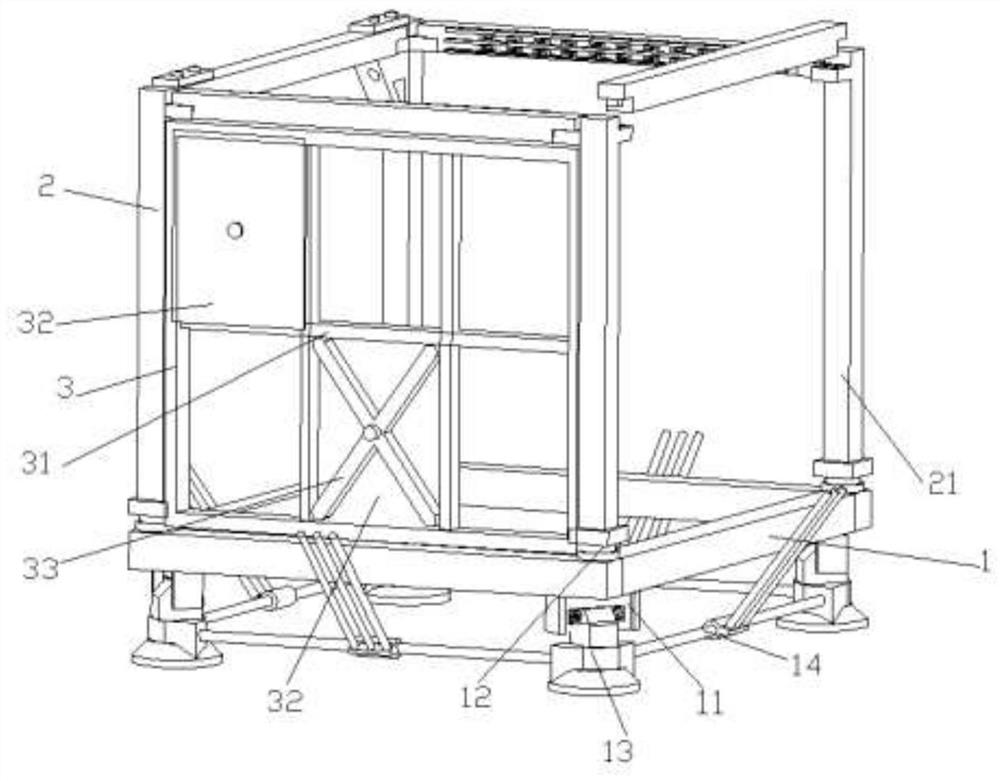

[0027] Embodiment 1: as figure 1 An assembled frame structure with wall panel splicing and foundation shock absorption is shown, including a foundation 1 that can be embedded underground, a load-bearing frame 2 set on the foundation 1, and a wall panel structure 3 set on the load-bearing frame 2;

[0028] The foundation 1 includes four trusses 11 arranged horizontally on the ground to form a rectangle, four load-bearing column support seats 12 fixed on the upper ends of the trusses 11 capable of supporting the load-bearing frame 2, and four pre-buried under the ground and movable set at the lower end of the trusses 11 The pre-embedded base 13, the shock-absorbing structural assembly 14 arranged between two adjacent pre-embedded bases 13;

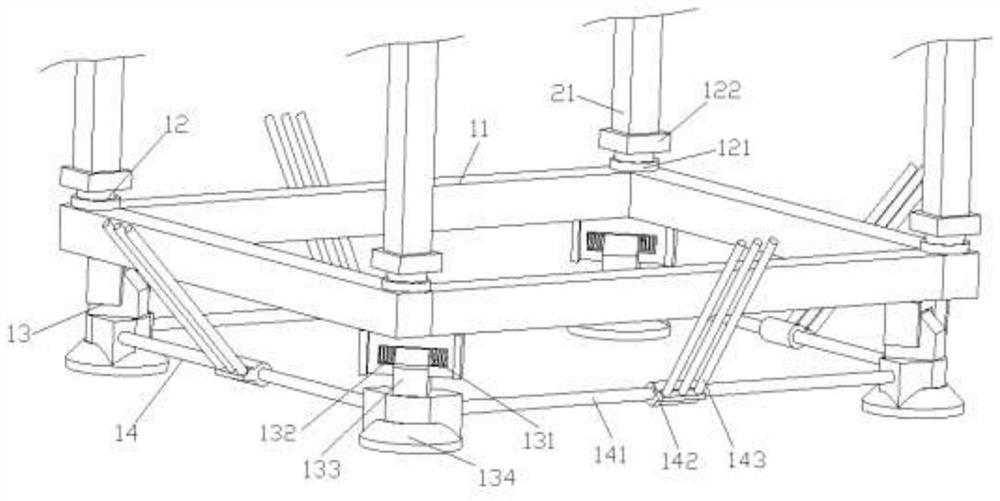

[0029] like figure 2 As shown, the embedded base 13 includes a sliding base arranged on the lower end surface of the truss 11, a base chute 131 arranged on the sliding pedestal, and elastic structural members 132 installed at both ends of ...

Embodiment 2

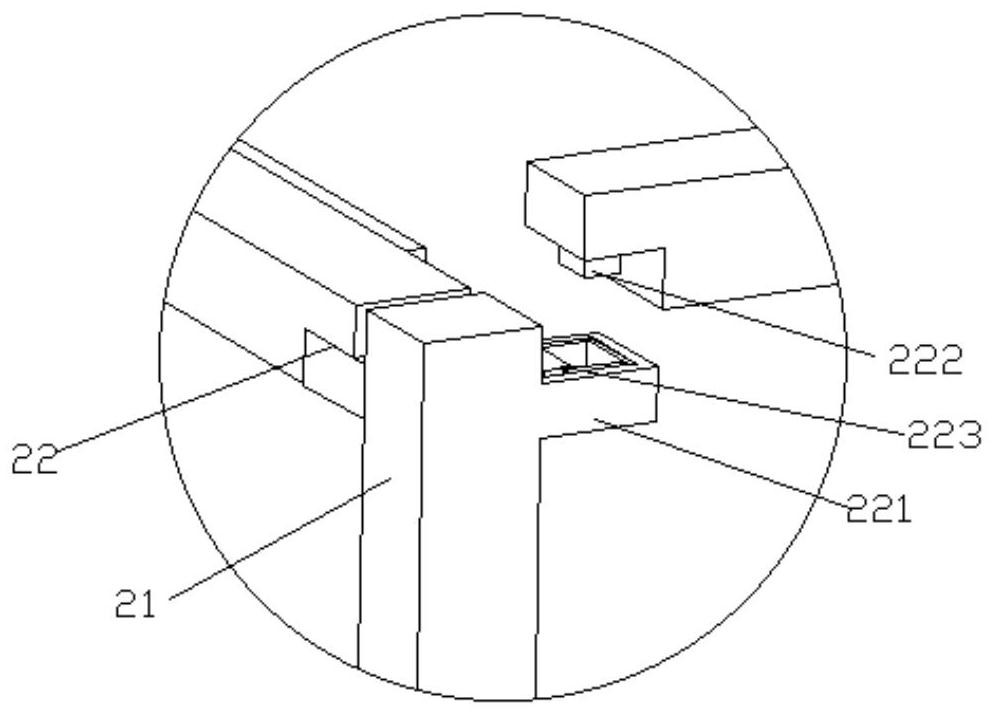

[0036] Embodiment 2: Different from Embodiment 1, as image 3 As shown, a connection structure 22 is provided at the connection between the load-bearing column 21 and the load-bearing beam.

[0037] The connection structure 22 includes a first connection block 221 arranged on the load-bearing column 21 and a second connection block arranged on the load-bearing beam; the upper end surface of the first connection block 221 is provided with a rectangular support slot, and the lower end surface of the second connection block is provided with There is a rectangular block 222, and a damping spring 223 is installed between the rectangular block 222 and the rectangular support slot.

[0038] The four sides of the rectangular clamping slot 221 are provided with shock absorbing springs 223 , and the shock absorbing springs 223 are provided with connection clips installed with the rectangular clamping blocks 222 .

Embodiment 3

[0039] Embodiment 3: Different from Embodiment 1, as Figure 4 As shown, the load-bearing column 21 and the load-bearing beam connection are provided with a reinforcement structure 23; the reinforcement structure 23 includes a triangular support 231 whose right-angled sides are connected with the load-bearing column 21 and the load-bearing beam respectively, and can be arranged on the load-bearing beam. The reinforcing plate 232 connected with 231 runs through the elastic connecting rod 233 used to connect the triangular support 231 and the reinforcing plate 232 on the load-bearing beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com