Digital detection method and device for geometric accuracy of machine tool

A technology of geometric accuracy and detection devices, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problem that the measurement data cannot quickly form an intuitive graphical report, it is difficult to ensure the consistency and accuracy of the detection results, and the skills of the operators Higher level requirements and other issues, to achieve automatic measurement and calculation analysis, facilitate archiving and digital management, and eliminate the effects of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

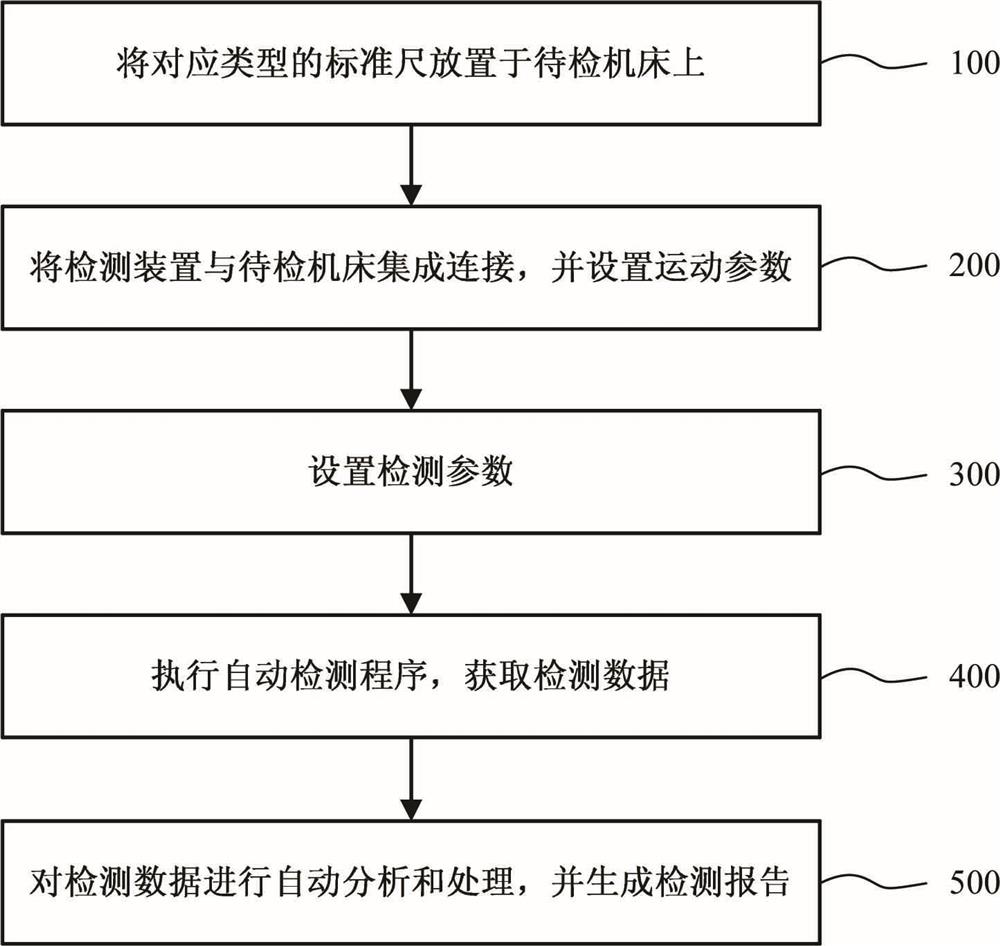

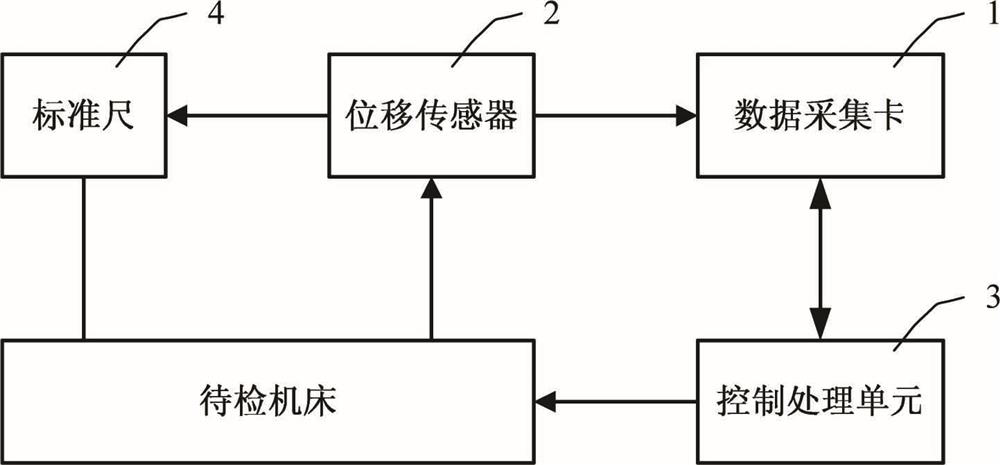

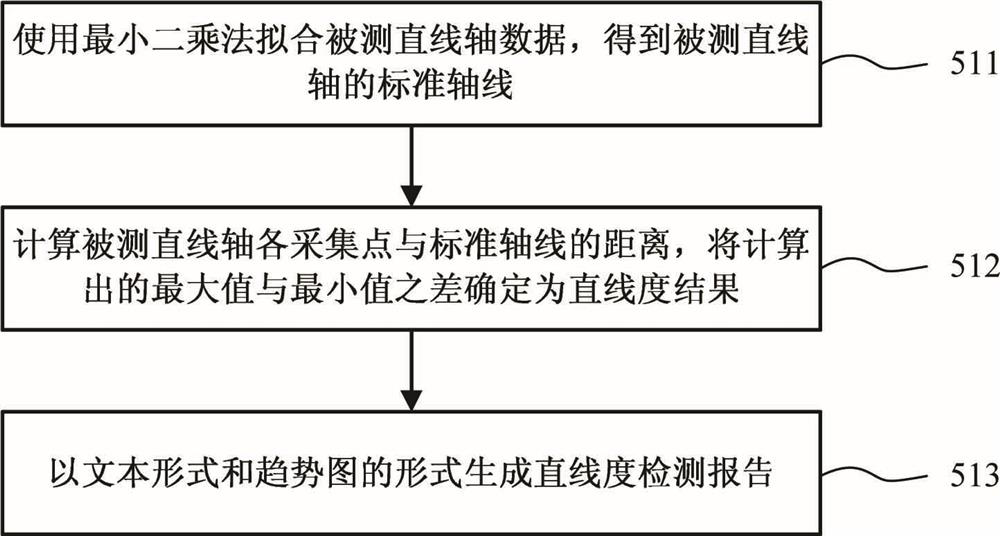

[0031] Such as figure 1 As shown, a digital detection method for the geometric accuracy of a machine tool of the present invention, by setting a standard ruler on the machine tool to be inspected, using a detection device to measure and calculate the geometric accuracy of the standard ruler, the geometric accuracy of the machine tool to be inspected is obtained indirectly, specifically Including the following steps:

[0032] Step 100, according to the measured geometric accuracy, place the corresponding type of standard ruler on the machine tool to be inspected. When the measured geometric accuracy is straightness, select the standard ruler for the standard ruler; when the measured geometric accuracy is verticality, select the standard ruler standard square feet;

[0033] Step 200, connect the detection device with the machine tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com