Special polyurethane self-adhesive double-core wire and manufacturing process thereof

A polyurethane, self-adhesive technology, applied in the field of wires, can solve problems such as corrosion and achieve the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

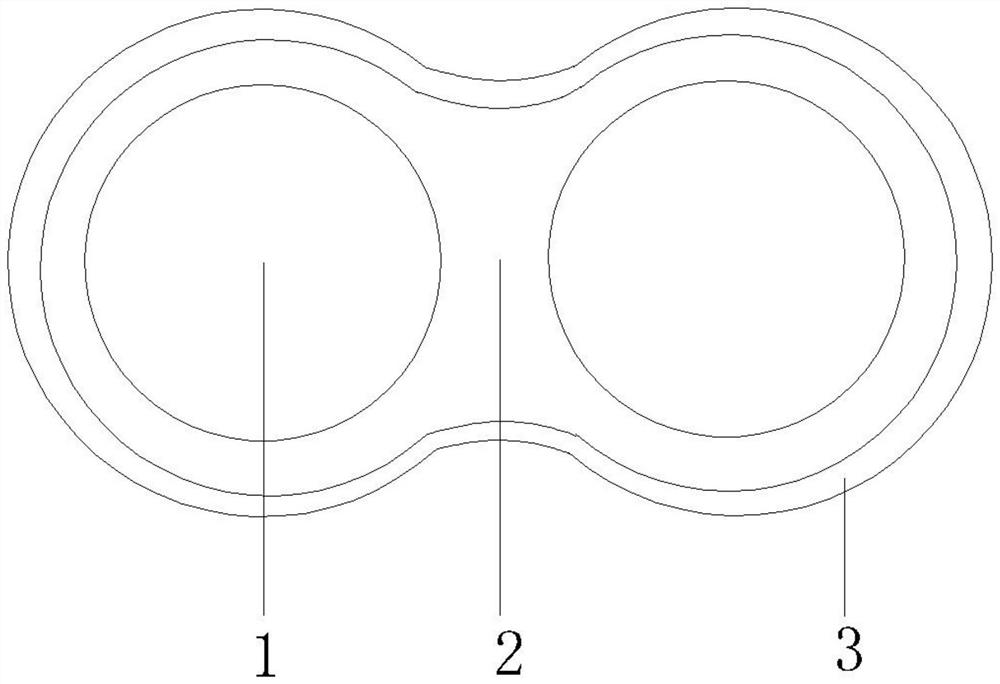

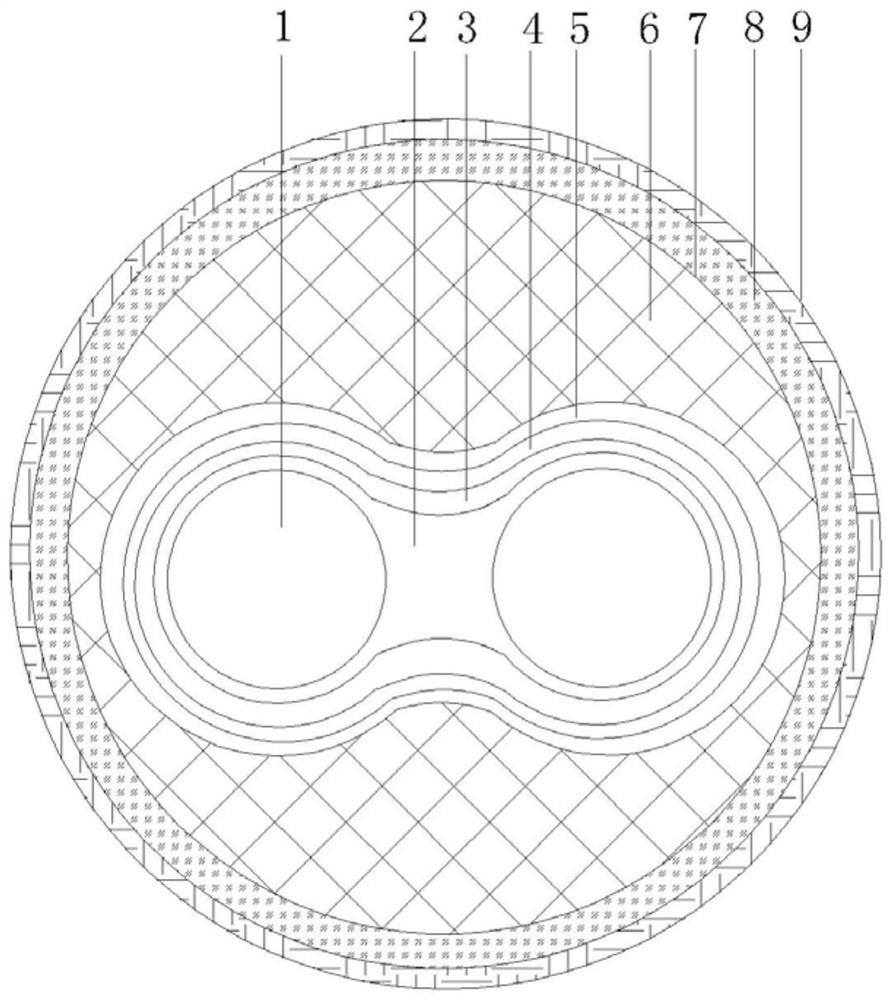

[0025] Such as figure 1 A special polyurethane self-adhesive twin-core wire is shown, which includes two parallel conductors 1, an insulating layer is provided on the outside of the conductors, and a polyurethane insulating layer 2 and a polyamide self-adhesive layer are sequentially provided on the insulating layer from the inside to the outside. Layer 3. A lubricating oil layer is arranged outside the polyamide self-adhesive layer.

[0026] A process for making a special polyurethane self-adhesive twin-core wire is characterized in that it comprises the following steps:

[0027] (1) Select two plates of 0.100mm copper billet, after being released by an independent pay-off system, annealing is carried out in an annealing furnace at about 500 degrees to remove the stress on the surface of the copper conductor, soften the copper conductor, and make it have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com