Rotary vibration type mussel meat and shell separator

A mussel meat and separator technology, which is applied in bivalve processing, crustacean processing, climate change adaptation, etc., can solve the problems of mussel shell residue, inability to obtain mussel meat, and unfavorable dry consumption of finished mussels, and achieve The effect of high centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

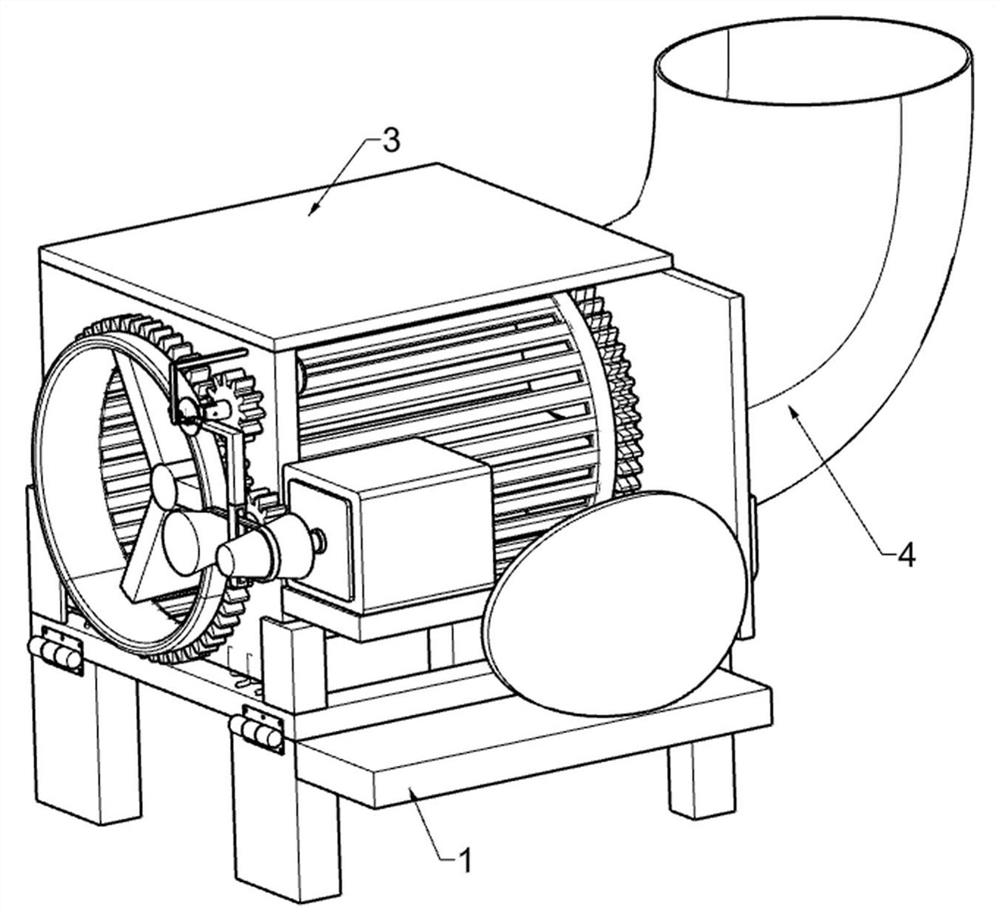

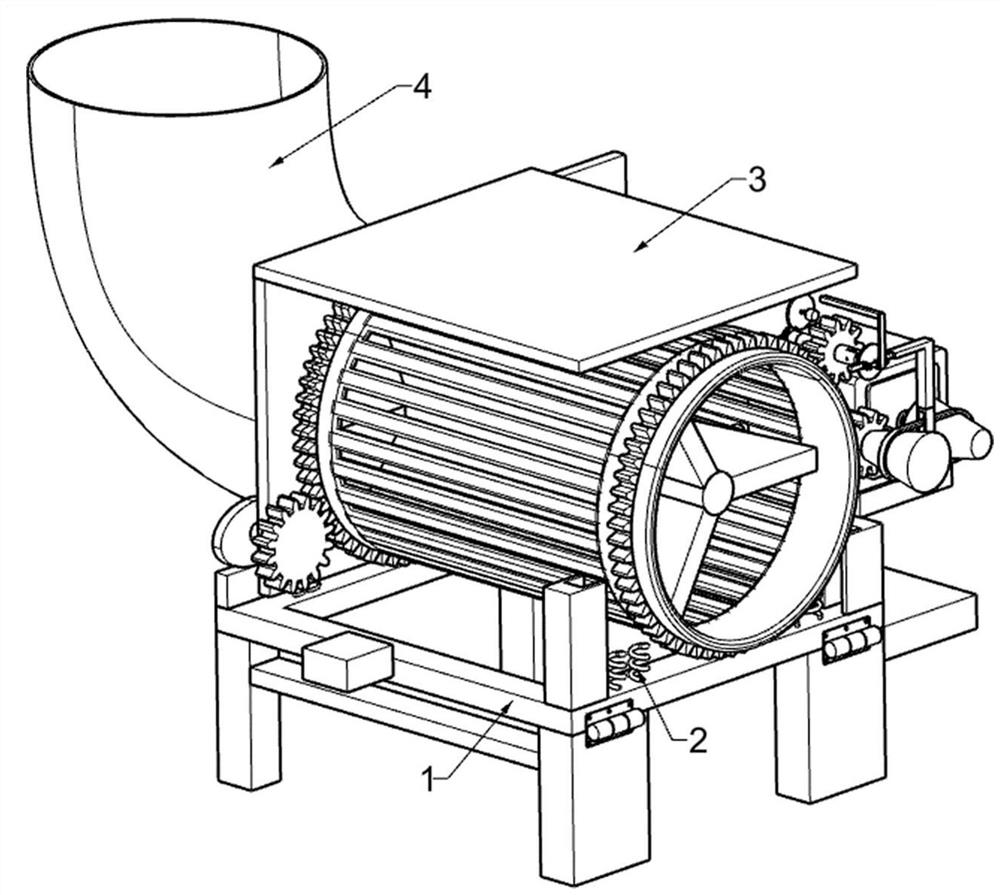

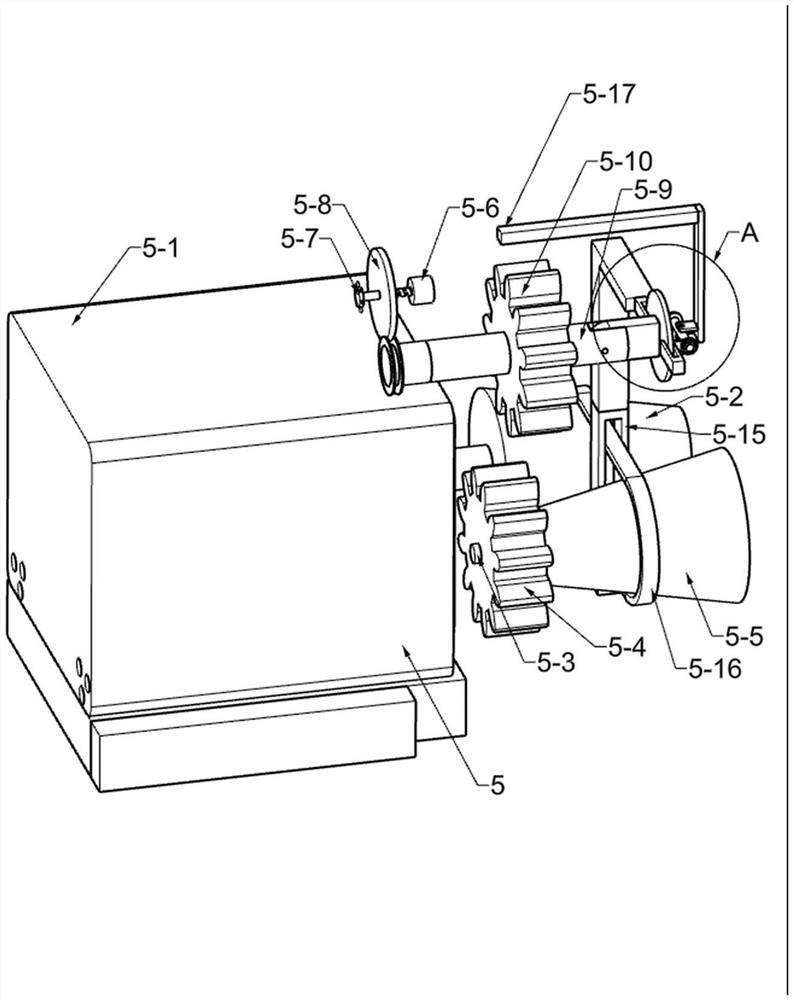

[0024] A rotary vibration type mussel meat shell separator, such as Figure 1-9 As shown, it includes a support frame 1, a support spring 2, a U-shaped support suspension plate 3, a feed pipe 4, a variable speed output assembly 5, a mussel meat throwing assembly 6, a vibration assembly 7 and a dumping assembly 8. On the support frame 1 Four groups of supporting springs 2 are fixedly arranged, and the upper ends of the four groups of supporting springs 2 are fixedly provided with a U-shaped supporting hanging plate 3, and the feeding pipe 4 for transporting mussels is fixedly arranged on one side of the U-shaped supporting hanging plate 3, and the speed change The output assembly 5 is arranged on the U-shaped support suspension plate 3, and the mussel meat throwing-out assembly 6 is arranged on the U-shaped support suspension plate 3 and is connected with the variable speed output assembly 5, and the variable speed output assembly 5 and the mussel meat throw-off assembly 6 can ...

Embodiment 2

[0030] On the basis of Example 1, such as Figure 5-7 As shown, the vibration assembly 7 used to drive the U-shaped support suspension plate 3 and the grooved circular roller 6-1 to vibrate up and down includes a third spur gear 7-1, a third transmission shaft 7-2 and a first cam 7-3 , the lower end of the U-shaped support suspension plate 3 is provided with two symmetrical third transmission shafts 7-2 through bearings, and one end of the third transmission shaft 7-2 is fixedly provided with the third spur gear 7-1 and the third spur gear 7- 1 meshes with another spur gear 6-2, and the end of the third transmission shaft 7-2 close to the feed pipe 4 is fixed with a first cam 7-3 and the first cam 7-3 is in contact with the support frame 1.

[0031] Slotted circular roller 6-1 can drive two third spur gears 7-1 and two third transmission shafts 7-2 to rotate through another spur gear 6-2, and two third transmission shafts 7-2 can drive two first The cam 7-3 rotates, and when ...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 7-8 As shown, the pouring assembly 8 for enabling the mussel shells in the slotted circular roller 6-1 to be poured out includes a slotted hole spur gear 8-1, an octagonal transmission shaft 8-2, a first helical gear 8- 3. The fourth transmission shaft 8-4, the second helical gear 8-5, the second cam 8-6, the slotted bump 8-7, the tumbler switch body 8-8, the reed 8-9, the return spring 8- 10. The supporting block 8-11, the connecting plate 8-12 and the connecting spring 8-13, the connecting plate 8-12 are slidably arranged on the U-shaped supporting hanging plate 3, and the connecting plate 8-12 and the U-shaped supporting hanging plate 3 A connection spring 8-13 is connected between them, the octagonal transmission shaft 8-2 is arranged on the connecting plate 8-12 through a bearing, and the slotted hole spur gear 8-1 is rotatably arranged on the U-shaped support suspension plate 3 and connected with it A third spur gear 7-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com