Ultrasonic separator

A separator and ultrasonic technology, applied in the field of separators, can solve the problems of silicon powder mixed with iron powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

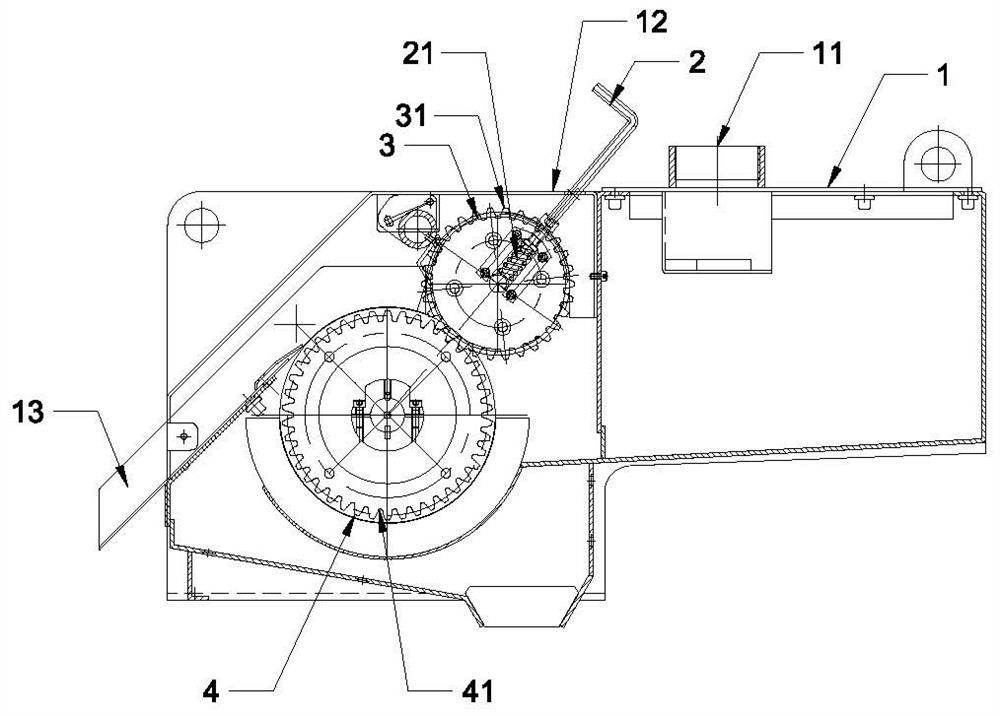

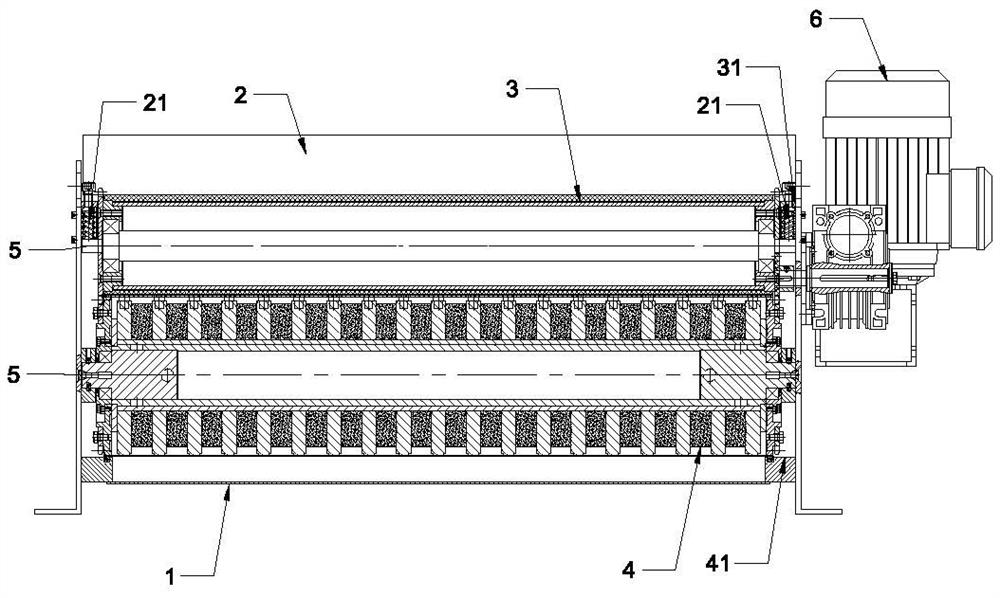

[0011] An ultrasonic separator, which includes a housing 1, a feed inlet 11 is provided on the top surface of the rear side of the housing 1, an iron powder outlet 12 is provided at the upper position of the front side, and a silicon powder outlet 13 is provided at the lower position of the front side; The front side of the housing 1 is arranged obliquely from top to bottom in sequence with a scraper 2, a magnet roller 3, and an ultrasonic drum 4 that are attached to each other. One of the ends is respectively equipped with a first gear 31 and a second gear 41 meshing with each other, the first gear 31 is fixedly installed on the shaft of the motor 6, and the motor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com