Robotic arm modular joint rapid electromechanical docking device

A technology of modular joints and docking devices, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of docking and locking failure, low connection strength, large weight, etc., and achieves high reliability, simple structure, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

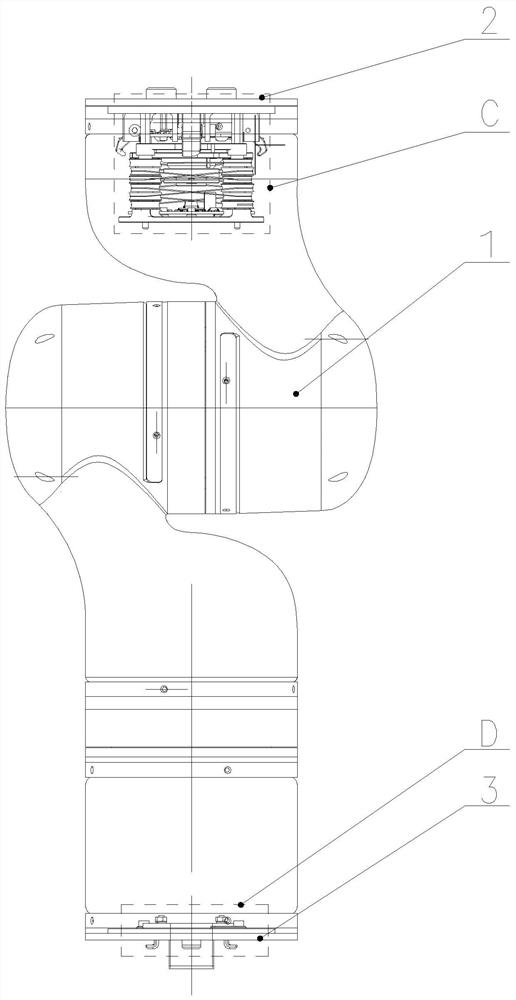

[0033] Specific implementation mode one: as figure 1 , Figure 8 and Figure 9 As shown, this embodiment discloses a fast electromechanical docking device for the modular joints of the manipulator, including the first connection module 3 and the second connection module 2 installed at both ends of the two manipulators 1 respectively, the first connection module 3 Cooperate with the second connection module 2 to realize the connection and disconnection between the two mechanical arms 1 .

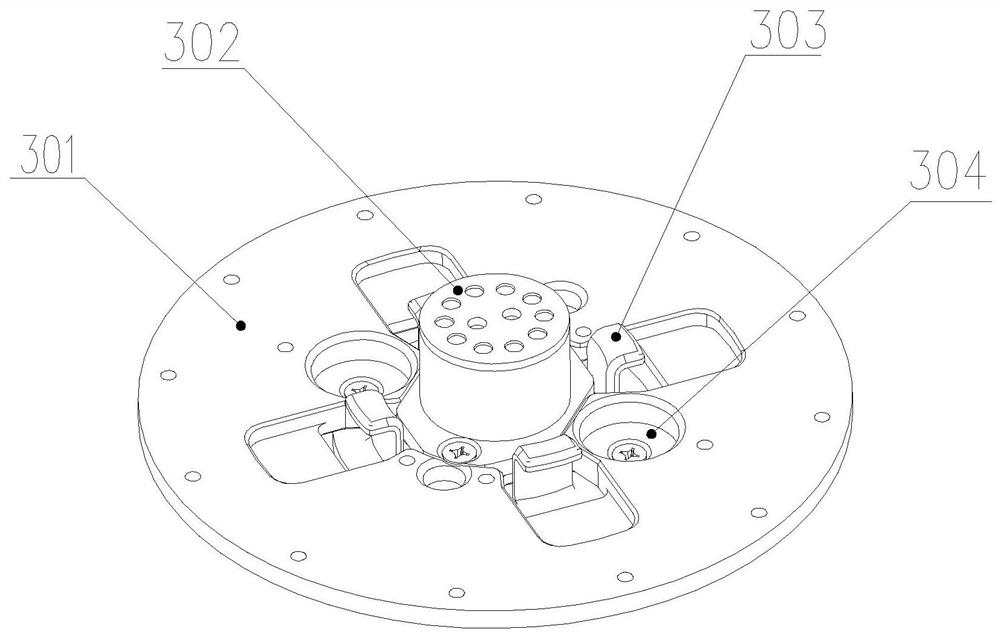

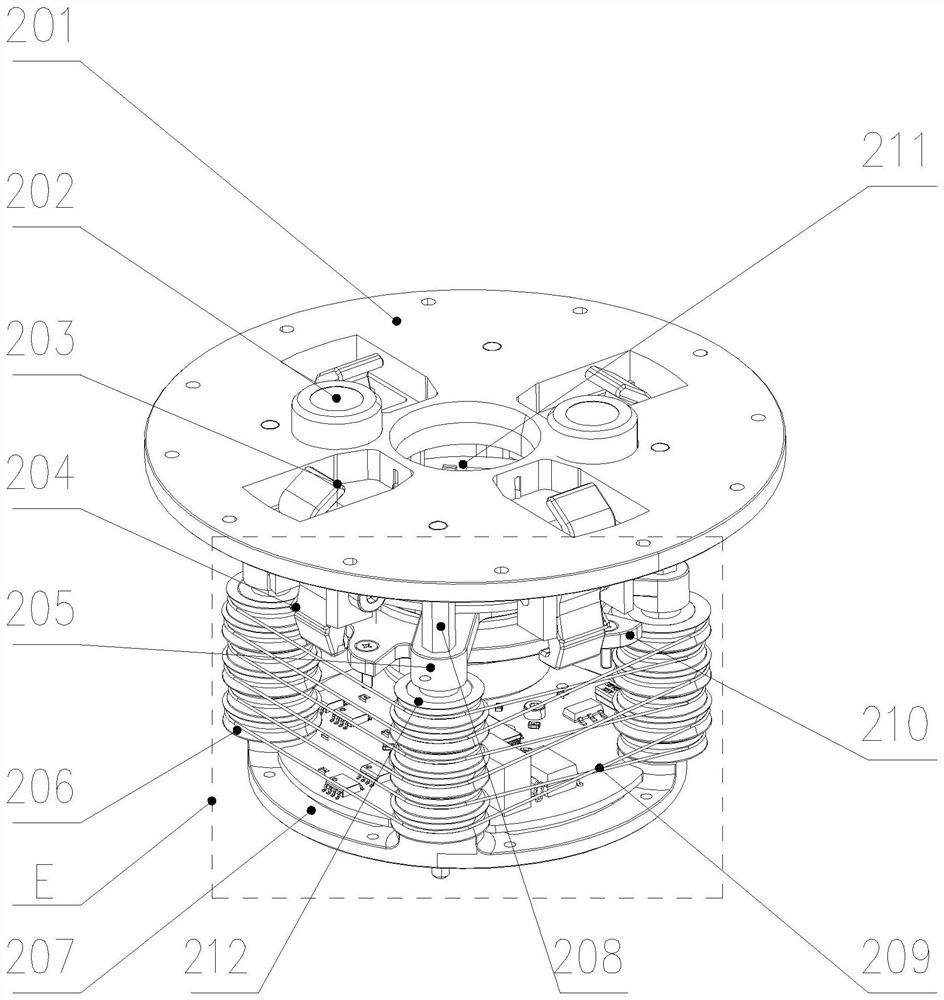

[0034] Further: if Figure 1-Figure 15 As shown, the first connection module 3 includes a first docking module body 301 (circular), an electrical connection contact 302, a hook seat and two magnetic seats 304; the first docking module body 301 is provided with Four grooves one through its thickness, the four grooves one is arranged symmetrically with respect to the center of the first docking module body 301, the hook seat is fixedly connected with one side of the first docking module body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com