Safe clamping mechanism for chemical raw materials

A technology of chemical raw materials and clamping mechanism, which is applied to manipulators, manufacturing tools, etc., can solve the problems of easy falling of raw materials, physical exertion, hidden dangers, etc., to achieve convenient position adjustment, convenient chemical experiments, and large position range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

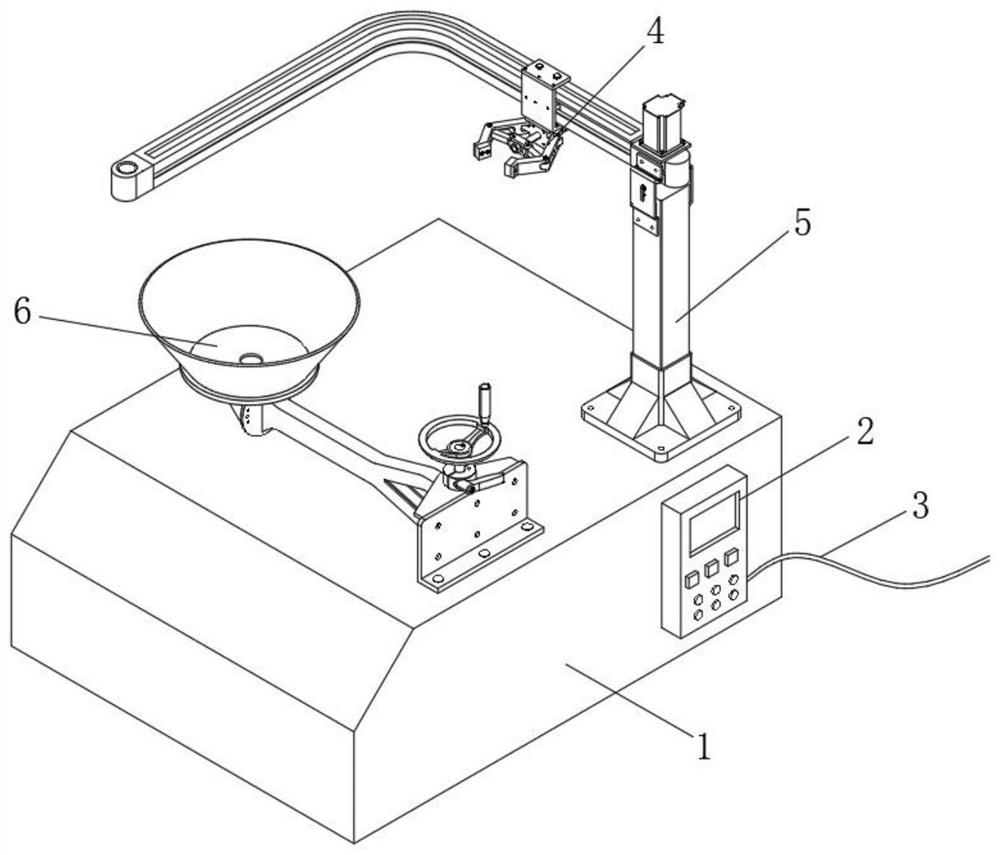

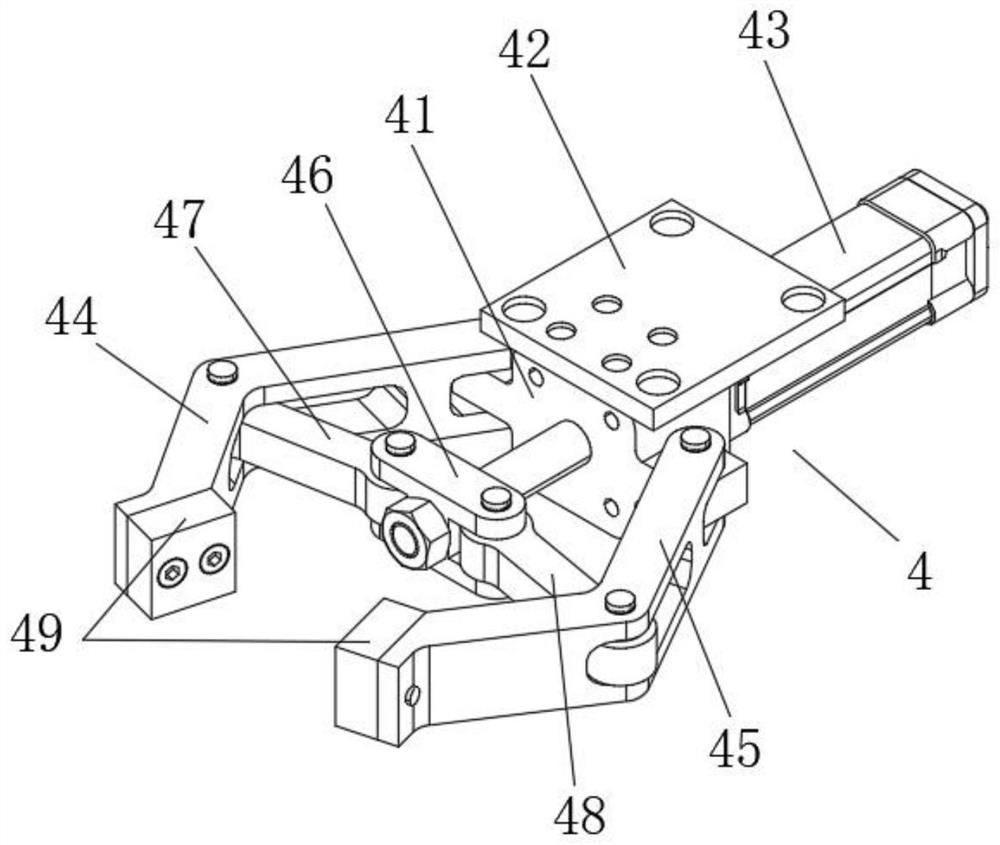

[0034] see Figure 1-2As shown, the present invention provides a safety clamping mechanism for chemical raw materials through improvement, including a test bench 1, a control panel 2, an external power cord 3, a clamping mechanism 4, a stable position adjustment device 5 and a scrap collection Device 6, a control panel 2 is set on the right side of the test bench 1, which is used to control the energized components to work. The control panel 2 is connected with an external power line 3, which can supply power to the energized components. The stable position adjustment device 5 is installed on the test bench 1. On the rear side of the upper end, the stable position adjustment device 5 is provided to adjust the position of the clamped chemical raw materials. The clamping mechanism 4 is installed on the stable position adjustment device 5. The clamping mechanism 4 is used for fast and stable clamping For chemical raw materials, a debris collection device 6 is installed on the rig...

Embodiment 2

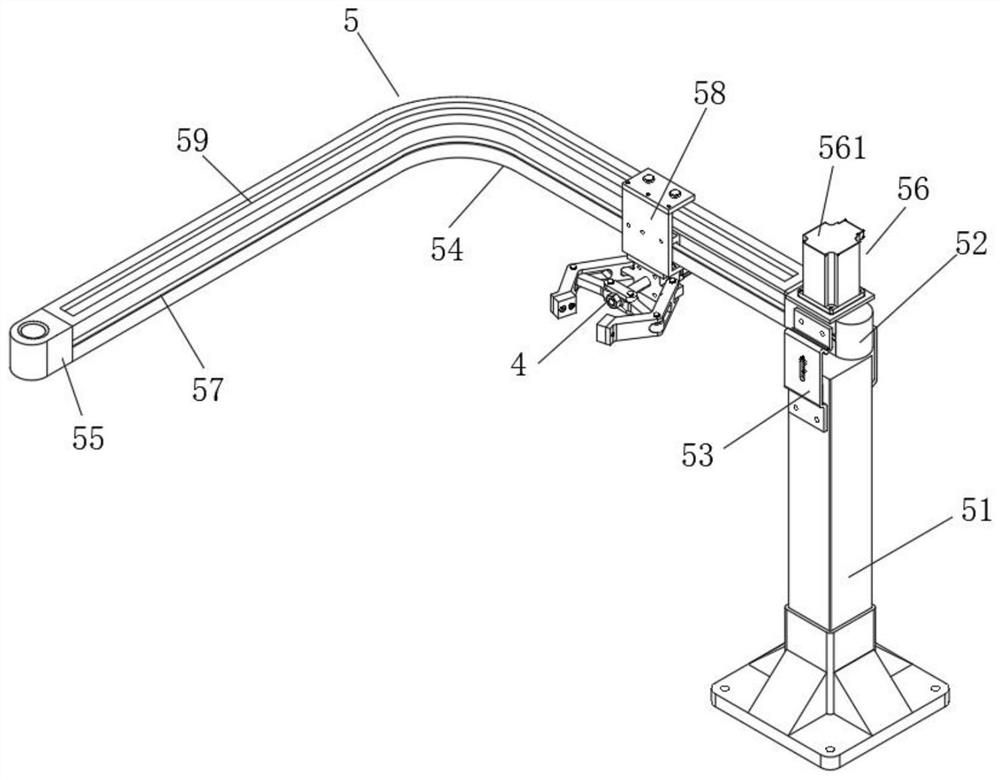

[0041] The present invention provides a kind of safe clamping mechanism that is used for chemical raw material through improvement here, and the first wheel seat 52, the fixed horizontal frame 54 and the second wheel seat 55 all communicate with each other inside, so that the transmission belt 565 can be connected from the fixed horizontal frame 54 Pass through the first wheel seat 52 and the second wheel seat 55 to drive and connect with the main runner 562 and the driven wheel 563 inside the two, the transmission belt 565 is arranged inside the fixed horizontal frame 54, the limit pulley 584 and the limit slideway 59 The inner side is slidingly connected so that the limit pulley 584 can slide inside the limit slideway 59, ensuring the stability of the slide mechanism 58 when sliding. The slideway 59 will not be stuck when sliding to the corner, so as to ensure smooth sliding of the sliding mechanism 58. The outer side of the rotating shaft 622 is fixedly connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com