Blowing and sucking machine

A blow-suction machine and machine head technology, which can be used in road cleaning, construction, cleaning methods, etc., can solve problems such as the inability to meet the needs of people of different heights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

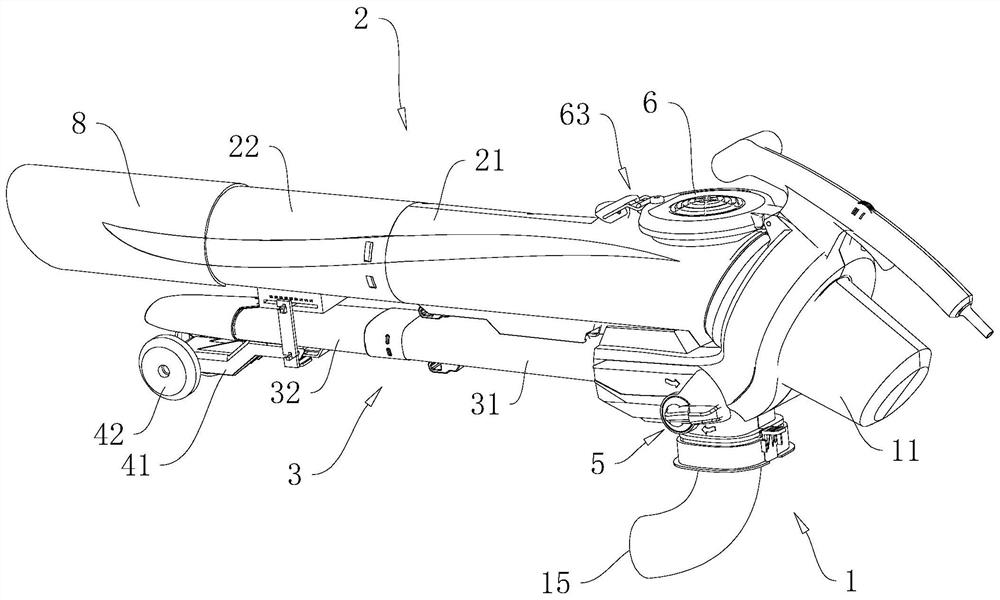

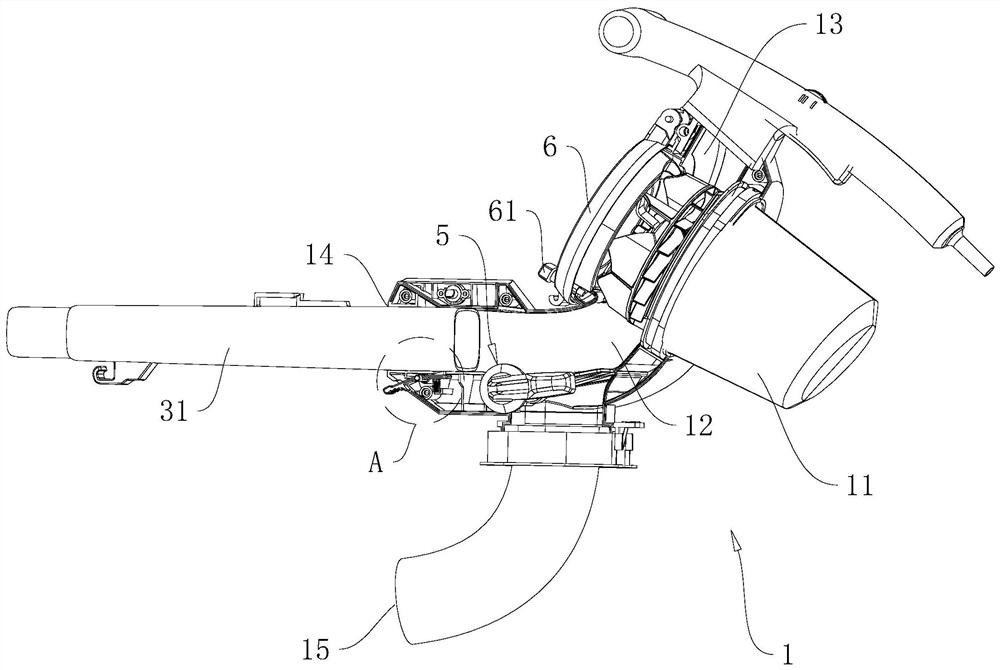

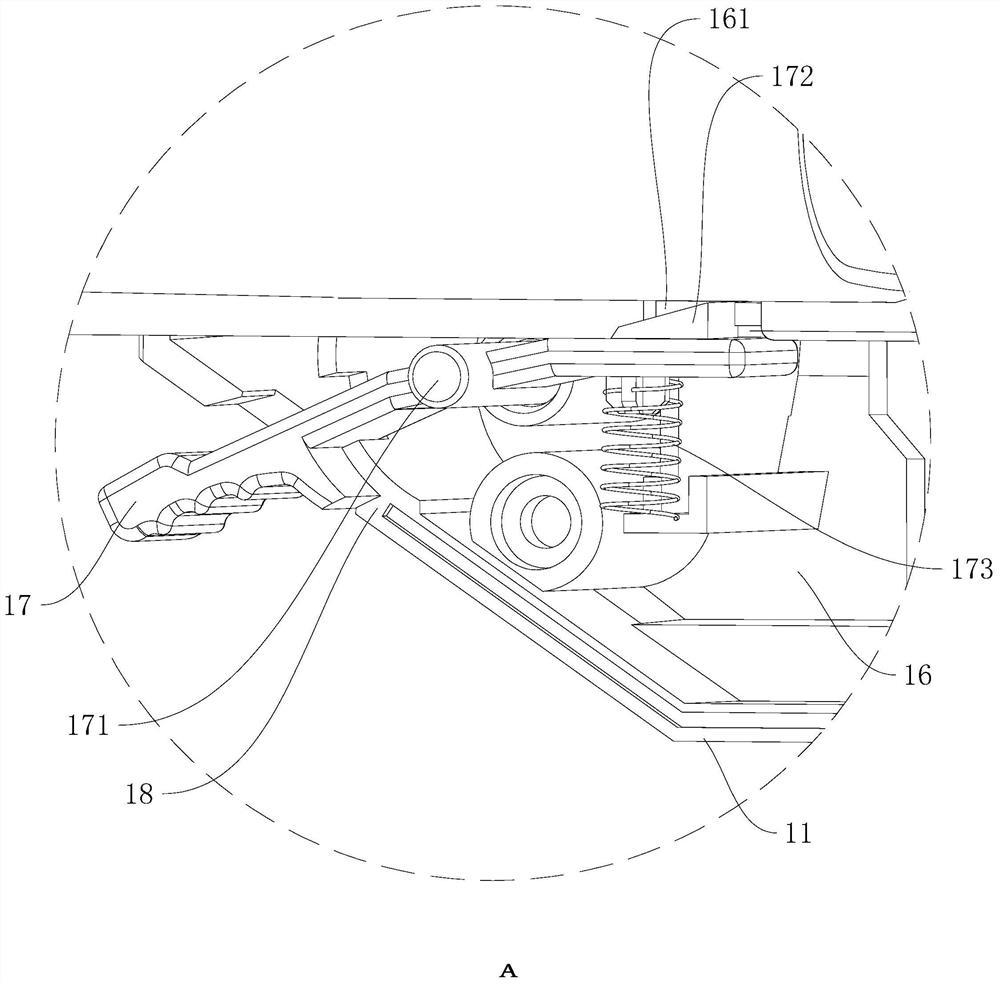

[0049] The following is attached Figure 1-15 The application is described in further detail.

[0050] The embodiment of the present application discloses a blowing and aspirating machine. refer to figure 1 and figure 2 , a blower, including a head 1, a suction pipe 2, a blower 3, a filter cover 6 and a mode switching switch 5, the head 1 includes a housing 11, and the cavity in the housing 11 is set as a flow chamber 12 , the housing 11 is provided with a suction port 13, a blowing port 14 and a discharge port 15, and a motor, a centrifugal fan blade and a crushing leaf mechanism are installed in the circulation chamber 12, and the centrifugal fan blade and the crushing leaf mechanism are driven by the motor at the same time, and the centrifuge The fan blade sucks the fallen leaves, and the fallen leaves sucked into the blower and aspirator are crushed into fine powder by the leaf crushing mechanism.

[0051] The blowing pipe 3 includes an upper blowing pipe 31 and a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com