Aquaculture waste collecting device

A technology for garbage collection and aquaculture, which is applied in water conservancy projects, open water surface cleaning, presses, etc., and can solve problems such as increasing the weight of the device, reducing the efficiency of garbage collection, and consuming energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

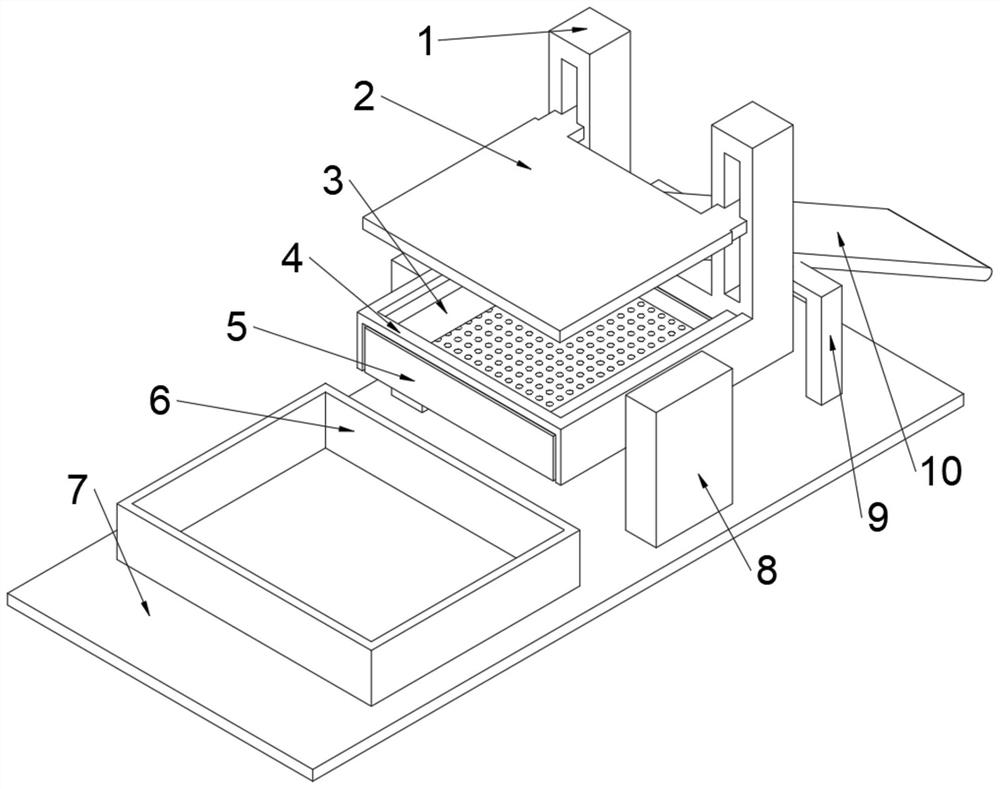

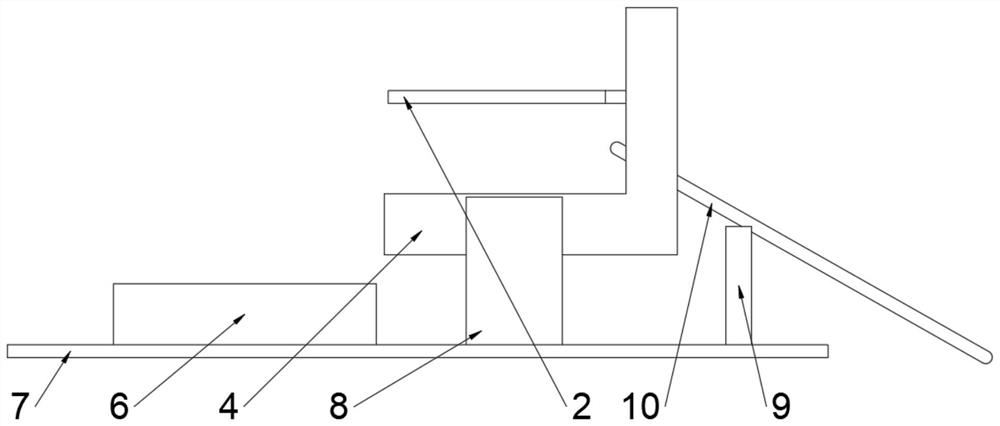

[0022] see Figure 1~5 , in embodiment 1 of the present invention, a kind of aquaculture garbage collecting device comprises main body 4, and the bottom of described main body 4 has leaking hole, and described main body 4 is slidably connected with two lateral compression arms 3, and described lateral compression The arm 3 is threadedly connected to the threaded rod 19, and the middle position of the threaded rod 19 is fixedly connected with a second gear 18, and the second gear 18 is meshed with the first gear 22, and the first gear 22 is fixedly connected to the second gear. On a rotating shaft 21, the first rotating shaft 21 is fixedly connected with the transverse compression motor 20, and the transverse compression motor 20 is fixedly connected with the main body 4, and the main body 4 is fixedly connected with two lifting platforms 1, and the lifting platform The inside of 1 is fixedly connected with the upper and lower compression motors 17, the upper and lower compress...

Embodiment 2

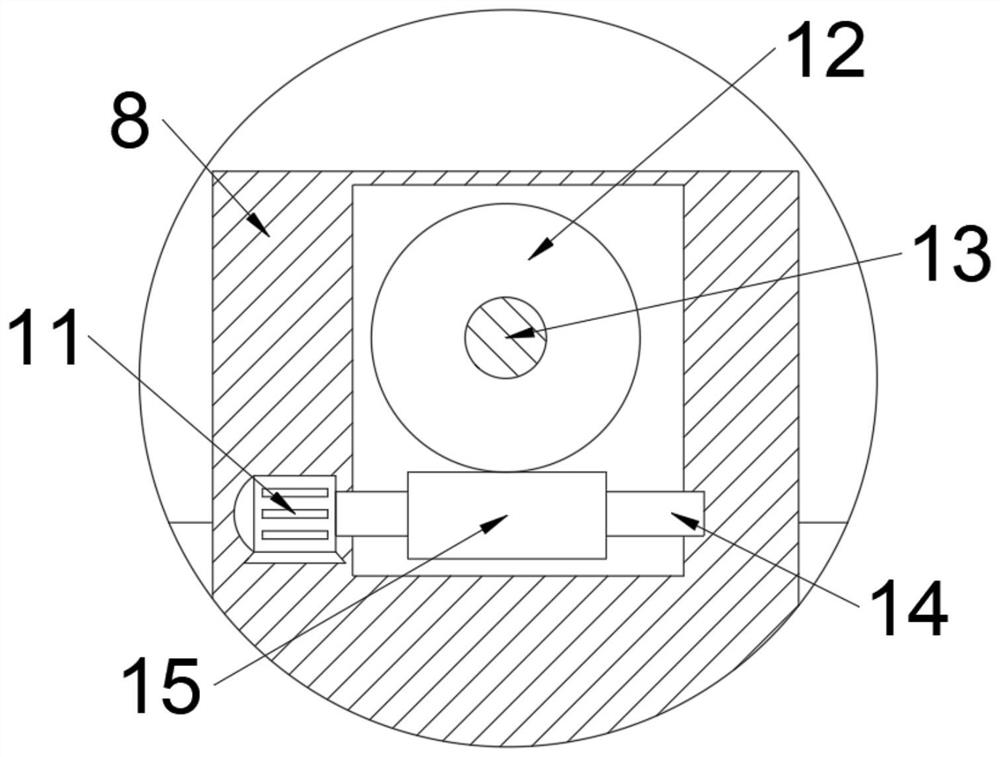

[0027] see Figure 1~5 , the main body 4 is rotatably connected to the support seat 8, the support seat 8 is fixedly connected to the bottom plate 7, the second rotating shaft 14 is fixedly connected inside the support seat 8, and the worm 15 is fixedly connected to the second rotating shaft 14 , the worm 15 is meshed with the worm gear 12 through gears, the worm gear 12 is fixedly connected to the third rotating shaft 13, the third rotating shaft 13 is rotatably connected to the support base 8, and the third rotating shaft 13 is fixedly connected to the main body 4 .

[0028] Wherein, a valve 5 is rotatably connected to the main body 4 .

[0029] The working principle of the present invention is: when the user operates the aquaculture garbage collection device of the invention, firstly start the conveyor belt 10, the conveyor belt 10 transports the garbage in the water to the main body 4, and then starts the up and down compression motor 17, and the up and down compression m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com