Movable culvert cleaning device and cleaning method

A cleaning device and technology for culverts, applied in the field of culverts, can solve the problems that cannot be cleaned with culverts, difficult to meet the requirements, and manual cleaning is inconvenient, and achieve the effects of increasing the spraying range, easy operation, and reducing the consumption of manpower, material resources and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

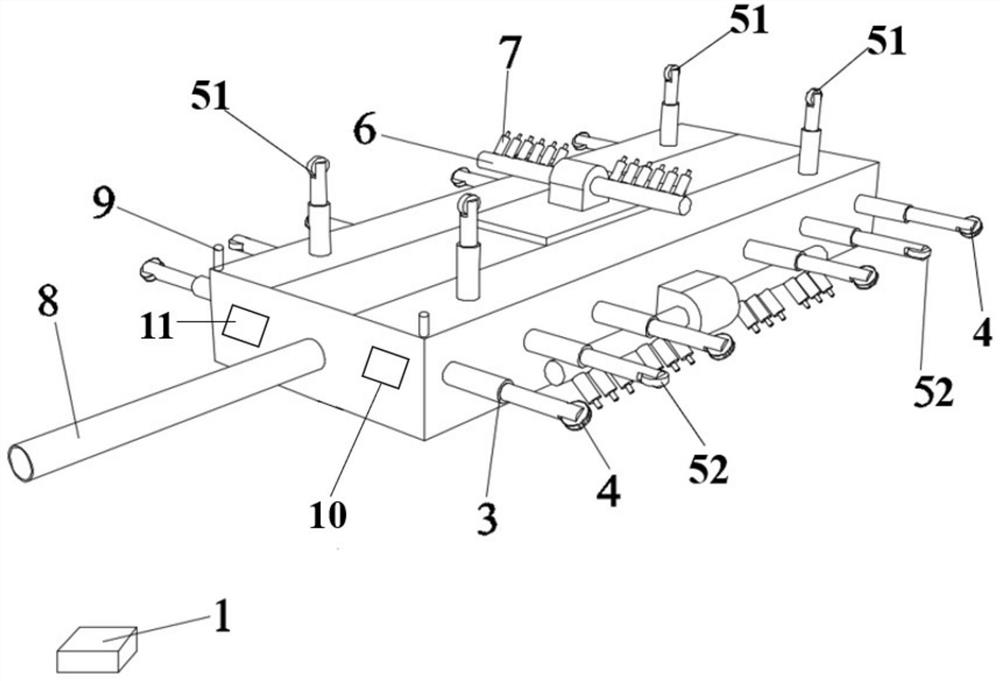

[0042] Such as figure 1 As shown, a movable culvert cleaning device includes a bottom plate and a water spray mechanism and a moving mechanism arranged on the bottom plate; the water spray mechanism includes a liquid storage tank 2 and a water sprayer 7 arranged in the bottom plate, and the liquid storage The tank 2 is connected with the sprinkler 7 through a pipeline, and the liquid storage tank 2 is connected with an external water source through a pipeline. Such as Figure 5As shown, the top surface and the bottom surface of the base plate are respectively equipped with a rotating wheel shaft 6, and the sprinkler 7 is installed on the rotating wheel shaft 6, and the rotating wheel shaft 6 is electrically connected with a second motor 61; the moving mechanism includes a telescopic unit and a rotating unit, telescopic The unit is arranged on the side wall of the bottom plate. The telescopic unit includes a telescopic shaft 3 and a first motor 31 electrically connected to the...

Embodiment 2

[0044] Except for the following content, all the other contents are the same as in Example 1.

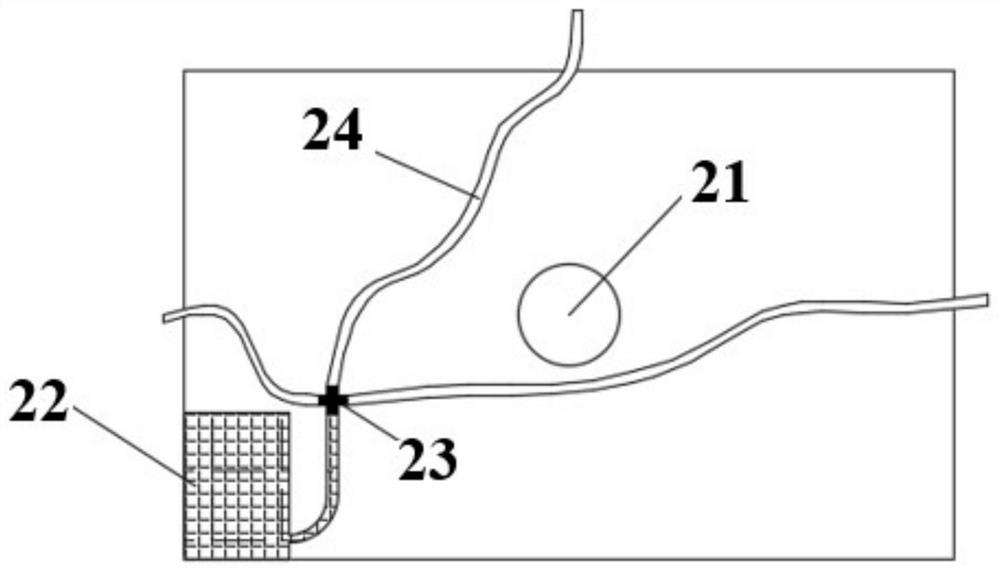

[0045] Such as figure 2 As shown, the liquid storage tank 2 is provided with a water inlet 21, and the water inlet 21 is connected to an external water source through the water inlet pipe 8 to fill the liquid storage tank 2 with water, and the water pump 22 passes the water in the liquid storage tank 2 through the water diversion valve 23 is shunted to outlet pipe 24, and water is sprayed by the rotatable ball nozzle 71 on the sprinkler 7 again.

Embodiment 3

[0047] Except for the following content, all the other contents are the same as in Example 1.

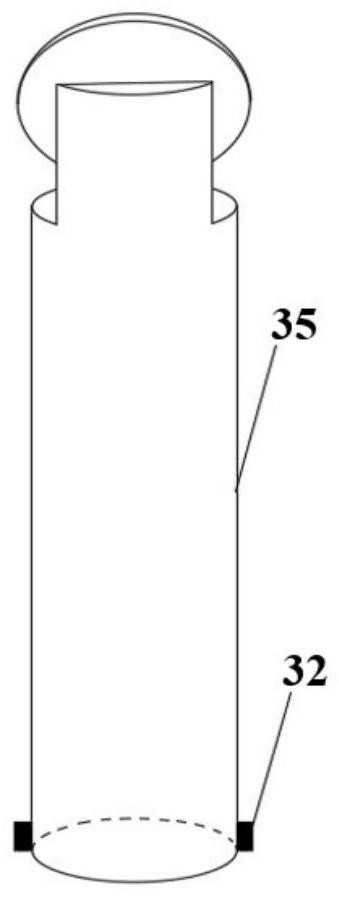

[0048] Such as Figure 3-1 and 3-2 As shown, the length of the telescopic shaft 3 can be adjusted according to the type of culvert to be cleaned, so that the cleaning device is suitable for various types of culverts. Wherein the lifter 33 is connected with the inner column 35, and the telescopic length of the telescopic shaft is adjusted by controlling the lifting of the lifter 33 by the controller 10. At the same time, a card slot 31 is set on the outer cylinder 34, and a stopper 32 is set on the inner column 35. The slot 31 and the block 32 work together to control the telescopic range of the telescopic shaft 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com