Automatic hoistway climbing device and working method thereof

A working method and hoistway technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve problems such as insufficient bearing capacity, shortened construction time, and small support force arm, so as to improve bearing capacity and improve Efficiency and reliability, the effect of increasing the support arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

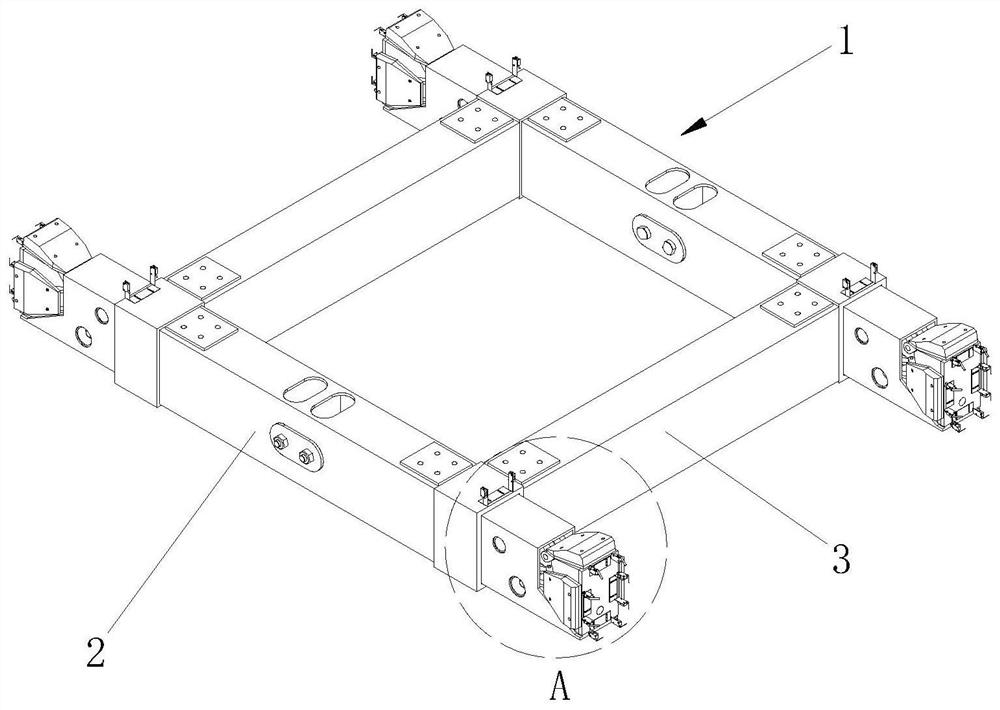

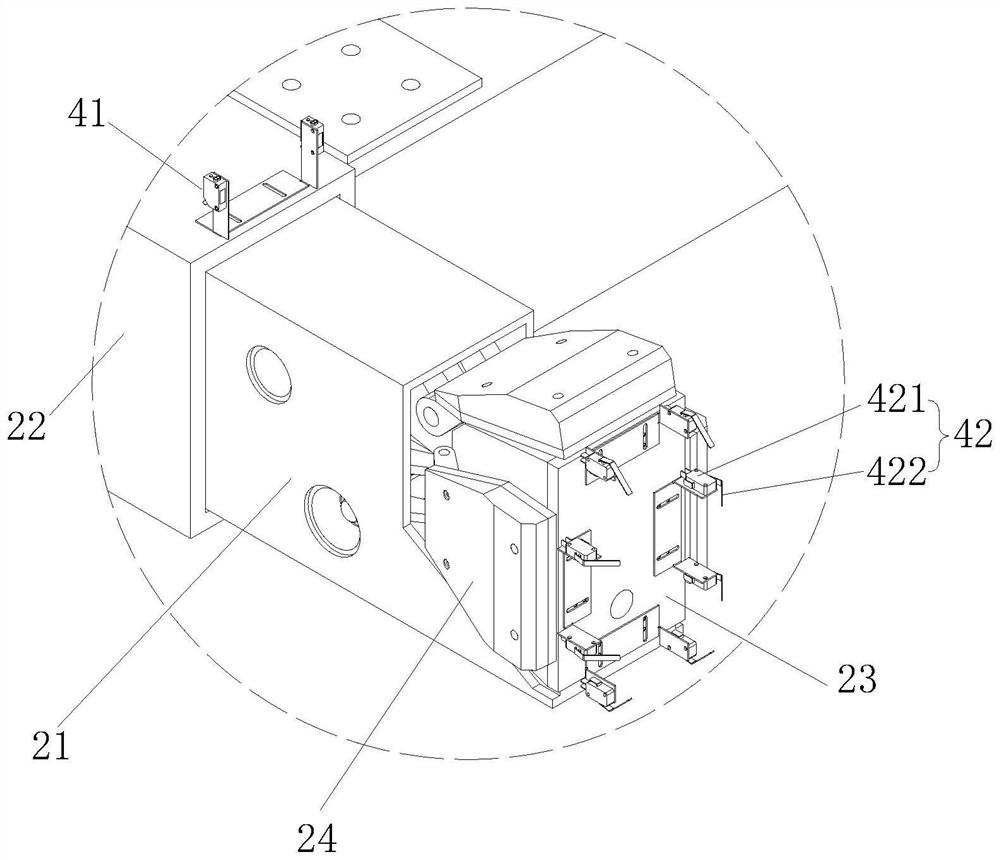

[0089] like Figure 1-Figure 3 As shown, this embodiment provides a support mechanism 1 for an automatic hoistway climbing device 12. The support mechanism 1 includes a support leg 2, a detection assembly and a connecting rod 3, wherein the support leg 2 is fixed on the climbing frame, and the climbing frame is supported by The legs 2 are fixed to the reserved holes 14, and the detection assembly is used to detect the reserved holes 14 arranged on the inner wall 13 of the hoistway, and the two supporting legs 2 and the two connecting rods 3 form a well-shaped structure and are fixed to each other. The supporting mechanism 1 has a well-shaped structure, which is convenient to be fixed on the outside of the climbing frame, and has good fixing and supporting effects.

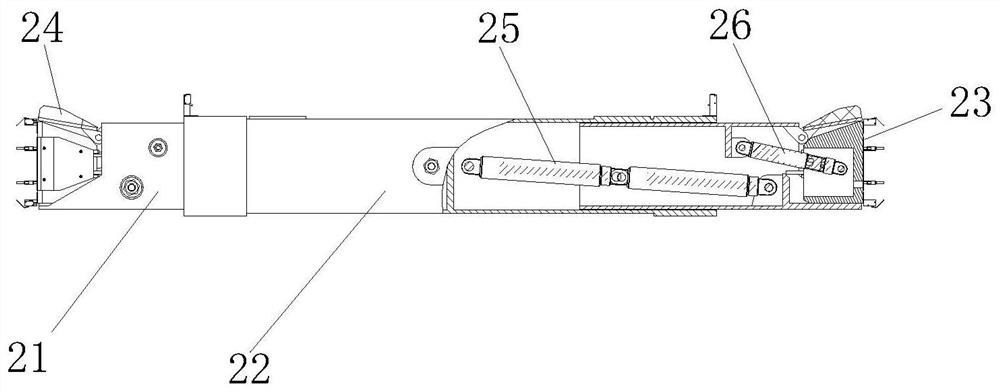

[0090] Further, as image 3 As shown, the supporting leg 2 includes a telescopic skeleton, a tension plate 24 and a tension drive assembly, wherein the telescopic skeleton includes an outer cylinder 22, an inner c...

Embodiment 2

[0097] like Figure 4-Figure 6 As shown, the present embodiment provides a hoistway automatic climbing device 12. The hoistway automatic climbing device 12 is arranged in the hoistway and includes a climbing frame, a jacking assembly and the support mechanism 1 described in Embodiment 1. The top of the climbing frame can be installed with a load , the supporting mechanism 1 is fixedly connected with the climbing frame, and the jacking component is fixedly connected with the climbing frame, and is used to drive the climbing frame to go up and down. The setting of the support mechanism 1 can improve the efficiency and reliability of fixing the hoistway automatic climbing device 12 to the hoistway.

[0098] Further, as Figure 4 and Figure 5 As shown, the climbing frame includes a first frame 5 and a second frame 6 arranged longitudinally, a part of the first frame 5 is sleeved in the second frame 6 , and the first frame 5 is arranged above the second frame 6 . Both the first...

Embodiment 3

[0108] This embodiment provides an automatic hoistway climbing device, including two hoistway automatic climbing devices 12 described in Embodiment 3 respectively arranged in different climbing shafts, and the upper ends of the support members 9 in the two hoistway automatic climbing devices 12 pass through The beam is connected, and a mounting plate is welded in the middle of the beam for installing the load. Specifically, the load is installed on the mounting plate in the middle of the beam, and the load is evenly shared on the hoistway automatic climbing devices 12 arranged in two different hoistways, so that the support is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com