Mine water spraying treatment method

A technology of water spraying and mine, applied in drainage, mining equipment, earth-moving drilling and other directions, can solve the problem of increasing the cost of mine construction, achieve good governance effect, reduce waste and reduce cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

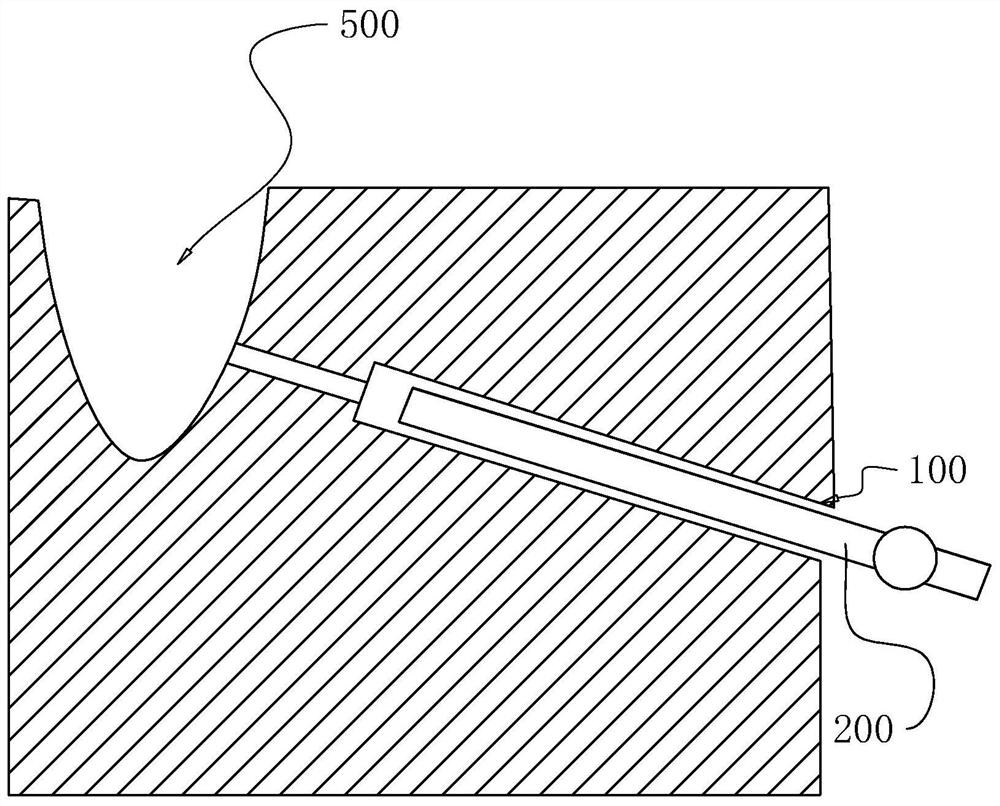

[0037] refer to figure 1 , the mine water spraying control method adopts the deep hole control water spraying step, S110, open the first deep hole 100 outside the water spraying range of the mine side wall along the direction close to the water outlet point, and insert the first casing 200 into the first deep hole 100 , continue to drill the first deep hole 100 until the first deep hole 100 communicates with the water outlet point 500 . In the present embodiment, the first deep hole 100 is processed by a drill bit with a diameter of 130 mm, and the hole depth is 4.5 m; the first sleeve pipe 200 with a diameter of 108 mm is inserted into the first deep hole 100, and the length of the first sleeve pipe 200 is 2 m. -4m, when the well wall to be drilled is marble, the length of the first casing 200 is 2m, and when the well wall to be drilled is skarn, the length of the first casing 200 is 4m. After inserting the first casing 200, use a drill bit with a diameter of 90 mm to insert...

Embodiment 2

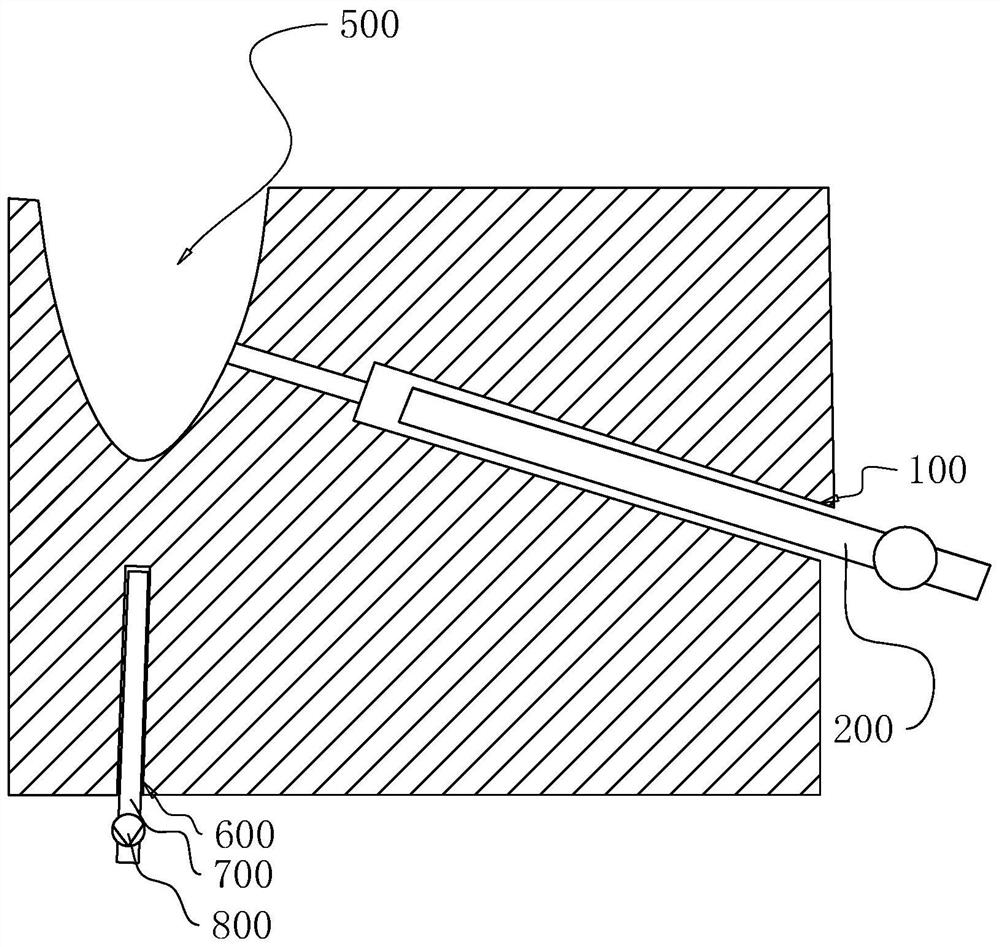

[0041] refer to figure 2 , the difference between this embodiment and the first embodiment is that: a third hole 600 is drilled near the water outlet point 500, and the third hole 600 is spaced apart from the water outlet point 500, and a drain pipe 700 is inserted in the third hole 600, and the drain pipe 700 is far away from One end of the third hole 600 communicates with the water pump 800, so that when the water pump 800 is running, a negative pressure is formed in the third hole 600, so that the water at the outlet point 500 and its vicinity flows toward the third hole 600. When the first slurry seeps out of the hole 600, the water pump 800 is stopped.

[0042] The implementation principle of a mine water spraying treatment method in this embodiment is as follows: start the water pump 800 to generate negative pressure at the third hole 600; open the first deep hole 100 and insert the first casing into the first deep hole 100 200, and seal the gap between the first casin...

Embodiment 3

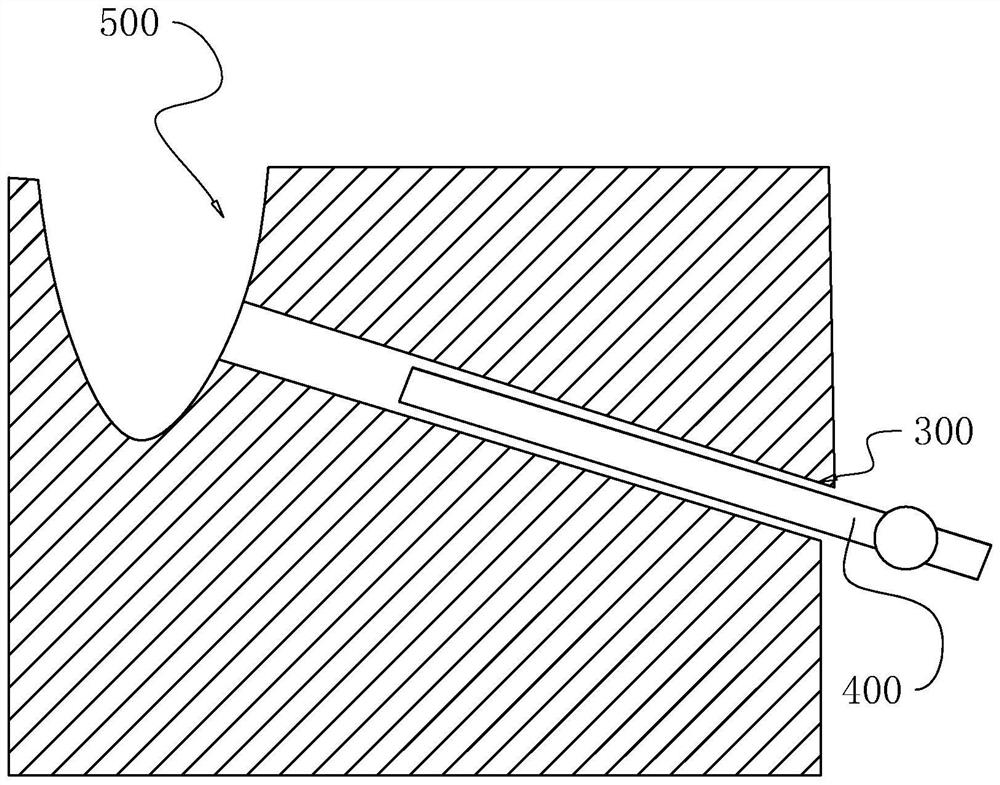

[0044] refer to image 3 , the mine water spraying treatment method is the shallow hole treatment water spraying step, S210, open the first shallow hole 300 in the direction of the mine side wall water spraying area, until the first shallow hole 300 is connected with the water outlet point 500, and the second casing 400 is inserted in the first shallow hole 300; in the present embodiment, the first shallow hole 300 is processed by a drill bit with a diameter of 40mm, and generally the processing depth of the first shallow hole 300 is 0-4m. When the depth of the first shallow hole 300 exceeds 4m After that, change another position and start drilling again. In other embodiments, the first shallow hole 300 can be processed with drill bits of other diameters; the second casing 400 with a diameter of 38mm is inserted in the first shallow hole 300, and the second set of The length of the pipe 400 is 0.5 m, and the depth of the first shallow hole 300 is greater than the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com