Compressor supporting structure

A technology of supporting structure and compressor, applied in the field of compressors, can solve the problems of affecting the service life of the compressor, the influence of compressor work, deepening the vibration of the whole machine, etc., to achieve the effect of improving the service life, improving the inhibition effect, and reducing the operating vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

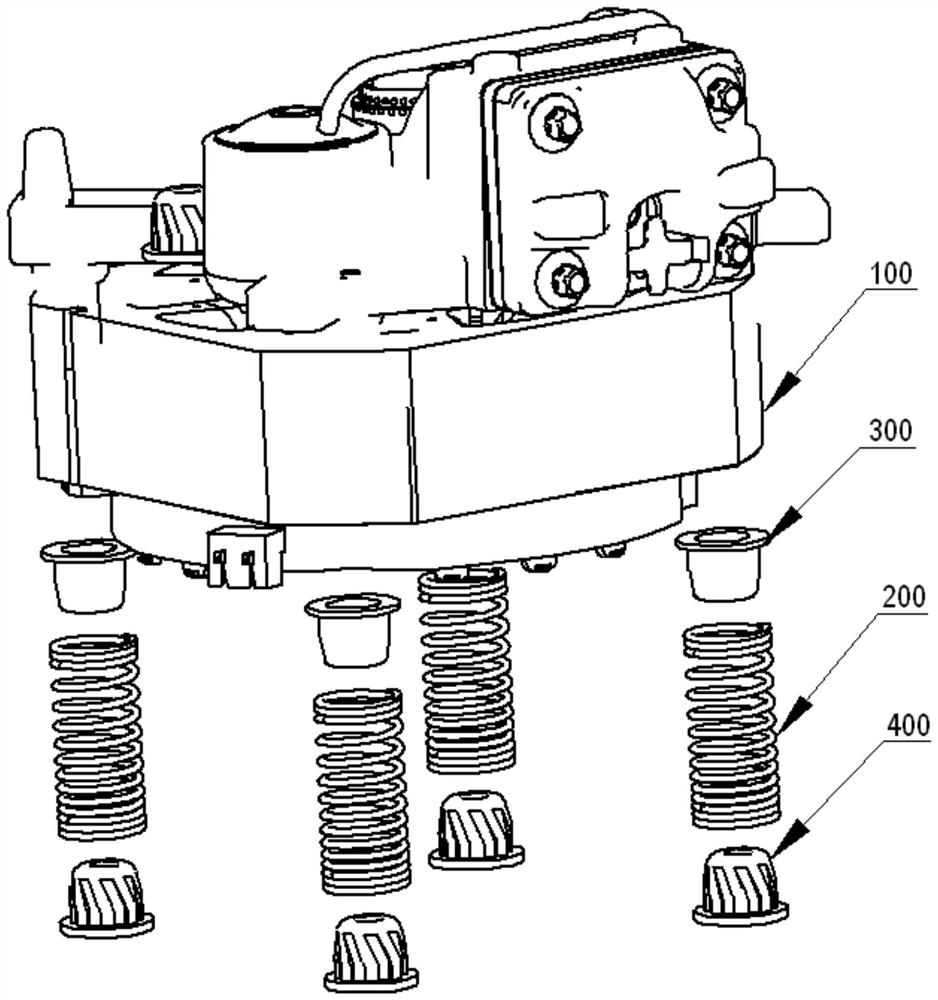

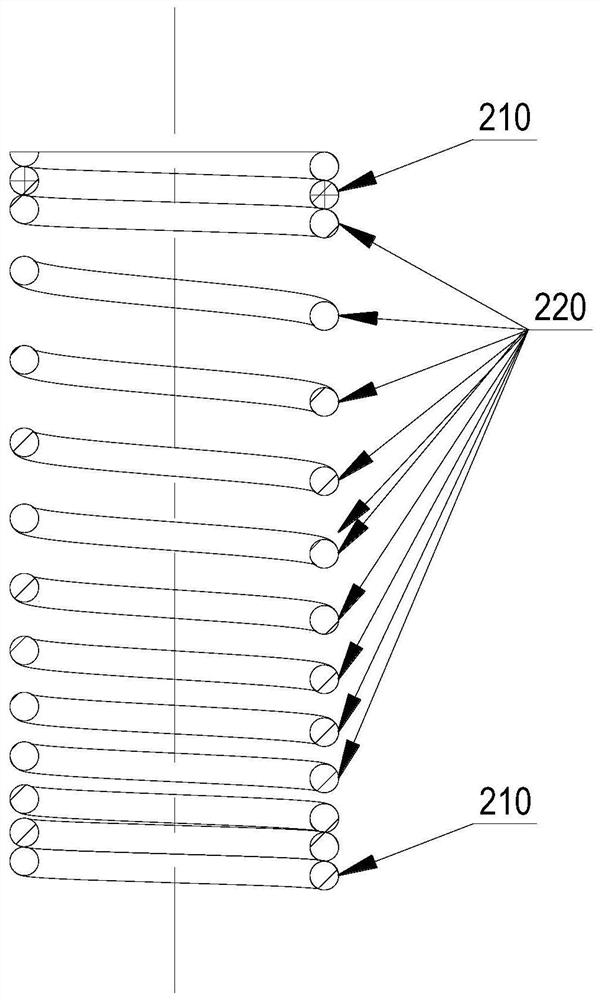

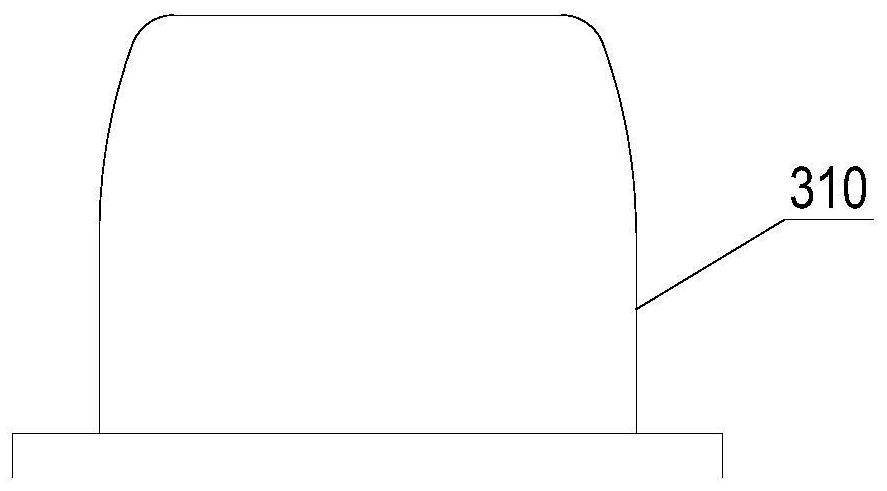

[0019] Such as figure 1 As shown, the compressor support structure of the present invention is provided with support components at the bottom of the compressor core 100, and the number of support components can be selected according to actual needs. In the present invention, in order to improve the stability of the compressor core 100, Four sets of support assemblies are adopted, and the four sets of support assemblies are evenly arranged on the bottom of the compressor core 100 in a rectangular shape. The support assembly is composed of a spring 200, an upper spring base 300 and a lower spring base 400; the upper spring base 300 is fixed on the bottom surface of the compressor core 100, and the lower spring base 400 is fixed on the support pin seat of the lower shell of the compressor core 100 , the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com