Servo quick pressure cylinder

A supercharged cylinder, fast technology, applied in the direction of fluid pressure converter, fluid pressure actuating device, belt/chain/gear, etc., can solve the problems of high failure rate, not very accurate positioning, affecting production, etc., to reduce Use requirements, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

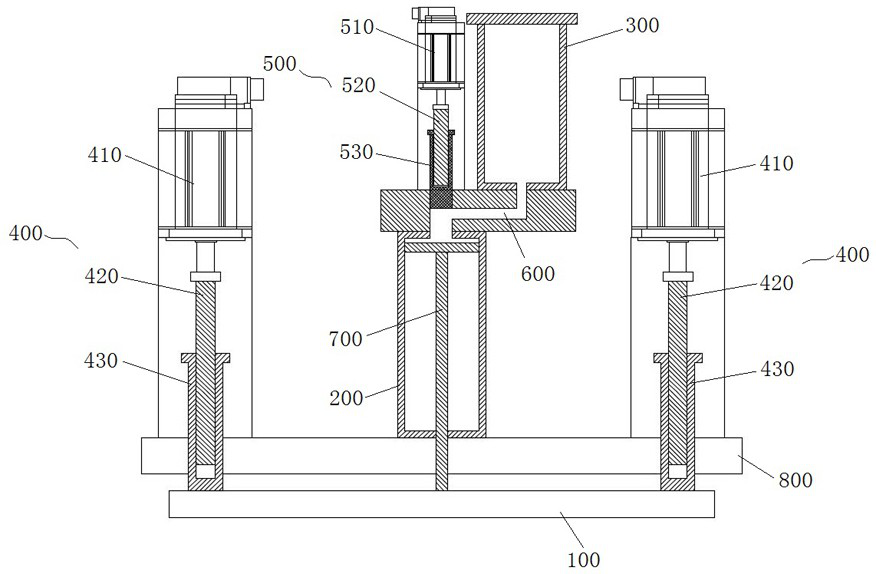

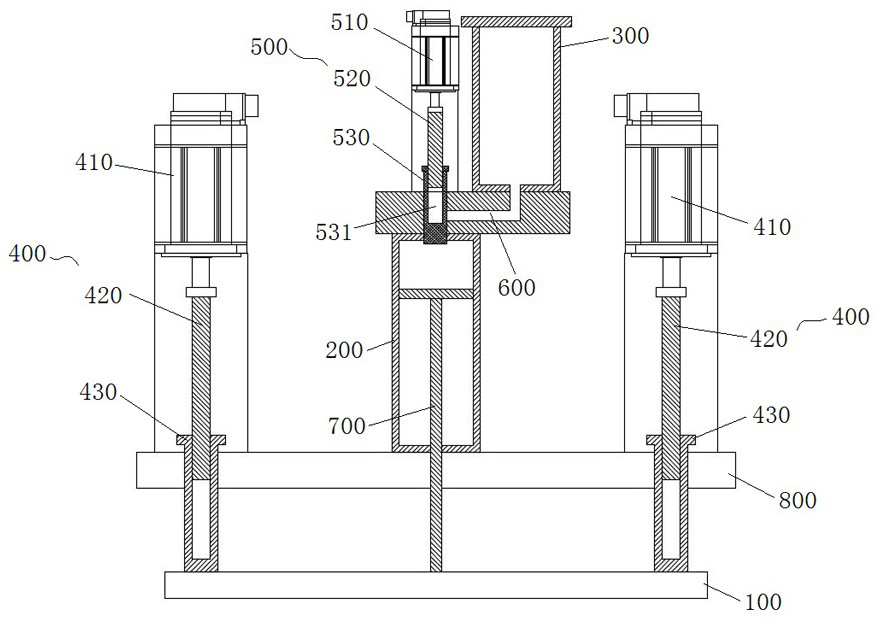

[0025] see figure 1 and figure 2 , a servo fast booster cylinder, including a connecting plate 100, a booster cylinder 200, an oil barrel 300, a first drive assembly 400 and a second drive assembly 500, the second drive assembly 500 is arranged on the booster cylinder 200 top, the bottom side of the oil barrel 300 is connected to the top side of the pressurized cylinder 200 to form an oil channel 600, the pressurized cylinder 200 is provided with a piston rod 700, and one end of the piston rod 700 increases The outer extension of the cylinder body 200 is connected to the middle of the connecting plate 100 , and the two ends of the connecting plate 100 are respectively connected with the first driving assembly 400 .

[0026] In this embodiment, the first drive assembly 400 includes a first servo motor 410, a first screw 420 and a main shaft 430, one end of the first screw 420 is connected to the first servo motor 410, and the other end is covered with It is installed in the ...

Embodiment 2

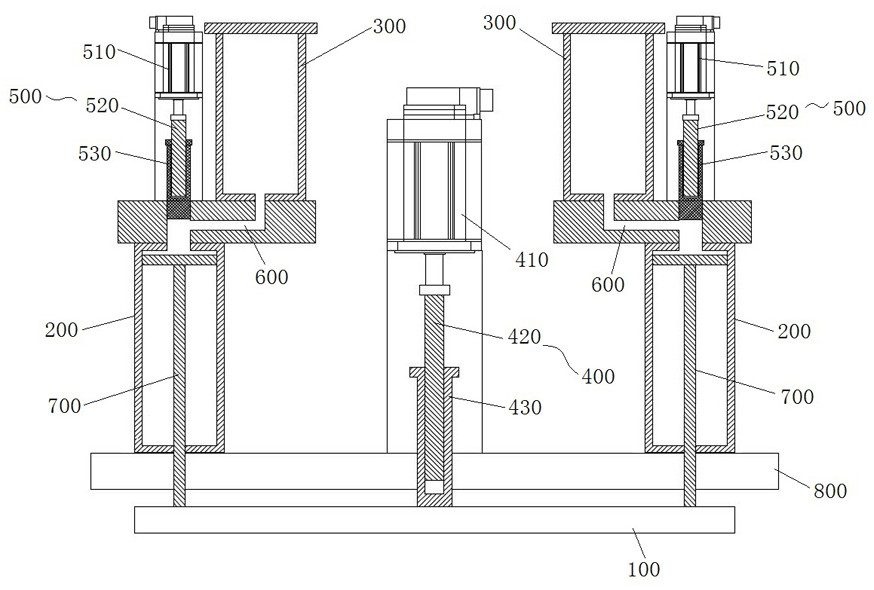

[0032] see image 3 and Figure 4 , the servo fast booster cylinder includes a connection plate 100, a booster cylinder 200, an oil barrel 300, a first drive assembly 400 and a second drive assembly 500, and the booster cylinder 200, the oil barrel 300 and the second drive There are two sets of assemblies 500 respectively, the second drive assembly 500 is arranged on the top of the pressurized cylinder 200, the bottom side of the oil barrel 300 is connected to the top side of the pressurized cylinder 200, and forms an oil channel 600, Piston rods 700 are arranged in the two groups of pressurized cylinders 200, and one end of the two groups of piston rods 700 extends to the outside of the pressurized cylinders 200, and is respectively connected to both ends of the connecting plate 100, and the ends of the connecting plate 100 The middle part is connected with a first driving assembly 400 .

[0033] The structure of the pressurized cylinder in this embodiment is basically the ...

Embodiment 3

[0035] see Figure 5 and Figure 6 , the servo fast booster cylinder includes a booster cylinder 200, an oil barrel 300, a first drive assembly 400 and a second drive assembly 500, the bottom side of the oil barrel 300 is connected to the top side of the booster cylinder 200, And form an oil channel 600, the second drive assembly 500 is connected to the oil channel 600, the inside of the pressurized cylinder 200 is provided with a piston rod 700, and the two ends of the piston rod 700 are respectively connected to the pressurized cylinder 200 The outside extends, and one end thereof is provided with a piston rod counterbore 710 , and the first drive assembly 400 is connected to one end of the piston rod 700 provided with the piston rod counterbore 710 .

[0036] In this embodiment, the first drive assembly 400 includes a first servo motor 410 and a first screw rod 420, one end of the first screw rod 420 is connected to the first servo motor 410, and the other end is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com