Graphite heat exchanger convenient to clean

A technology for graphite heat exchangers and heat exchangers, which is applied to cleaning heat transfer devices, lighting and heating equipment, flushing and other directions, can solve the problems of difficulty in graphite particles, reduced working efficiency of graphite heat exchangers, waste of workers' time, etc. The effect of reducing the cost of use, improving work efficiency and practicability, and saving workers' time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

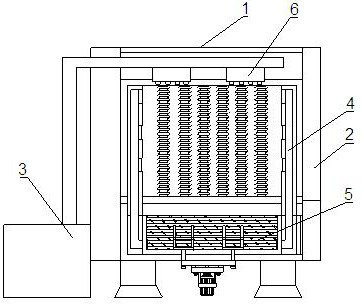

[0026] Such as Figure 1-5 As shown, the present invention provides a graphite heat exchanger that is easy to clean, including a graphite heat exchanger body 1, the graphite heat exchanger body 1 includes a heat exchanger shell 2, and the top of the inner cavity of the heat exchanger shell 2 is fixedly installed There is a washer 6, a water tank 3 is fixedly installed on the side bottom of the heat exchanger shell 2, a vacuum cleaner 4 is fixedly installed on the side of the inner cavity of the heat exchanger shell 2, and a water reservoir is fixedly installed on the bottom of the inner cavity of the heat exchanger shell 2 5. The washer 6 includes a connection seat 63, and the top of the connection seat 63 is fixedly connected to the top of the inner cavity of the heat exchanger shell 2. The bottom of the cavity is fixedly connected, and the top of the water tank 3 is fixedly equipped with a water pipe 31. One end of the water pipe 31 extends to the inside of the heat exchange...

Embodiment 2

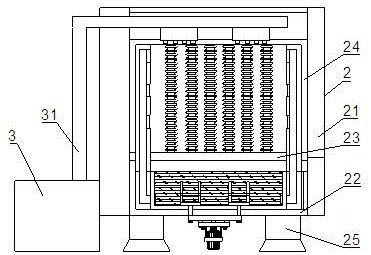

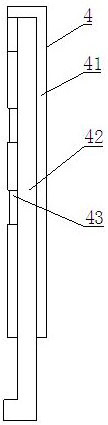

[0031] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the vacuum cleaner 4 includes a casing 41, the inside of the casing 41 is fixedly connected with a dust suction pipe 42, and the side of the casing 41 is provided with a suction port 43. One end of the suction pipe 42 extends to the inside of the pool 51 and is fixedly connected with the pool 51. The bottom end of the back of the pool 51 is fixedly connected with a drain pipe. The scattered graphite particles are absorbed and transported to the water pool 51 for treatment, which reduces the possibility of graphite particles escaping to the equipment and affecting the use of the equipment, and further improves the use effect and practicability of the equipment.

Embodiment 3

[0033] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner side of the shell 41 is fixedly connected with an inner baffle 23, and the upper surface of the inner baffle 23 is fixedly installed with a heat exchanger pipe, and the outer shell The outside of 41 is fixedly connected with an inner retaining wall 24, and one side of the inner retaining wall 24 is fixedly connected with the inner side of the outer baffle 21, and the four corners of the bottom surface of the base plate 22 are fixedly equipped with anti-seismic feet 25, and through the design of the inner baffle 23 and the inner retaining wall 24, The stability of the equipment is improved, and at the same time, the anti-seismic feet 25 transmit the force generated by the equipment to the ground, so that the working efficiency and service life of the equipment are further improved.

[0034] Let's talk about the working principle of the eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com