Repeated crushing device for plastic particle materials

A plastic particle and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of inconvenient crushing effect and inconvenient multi-angle crushing, etc., and achieve the effect of improving work efficiency and practicability, and multi-angle crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

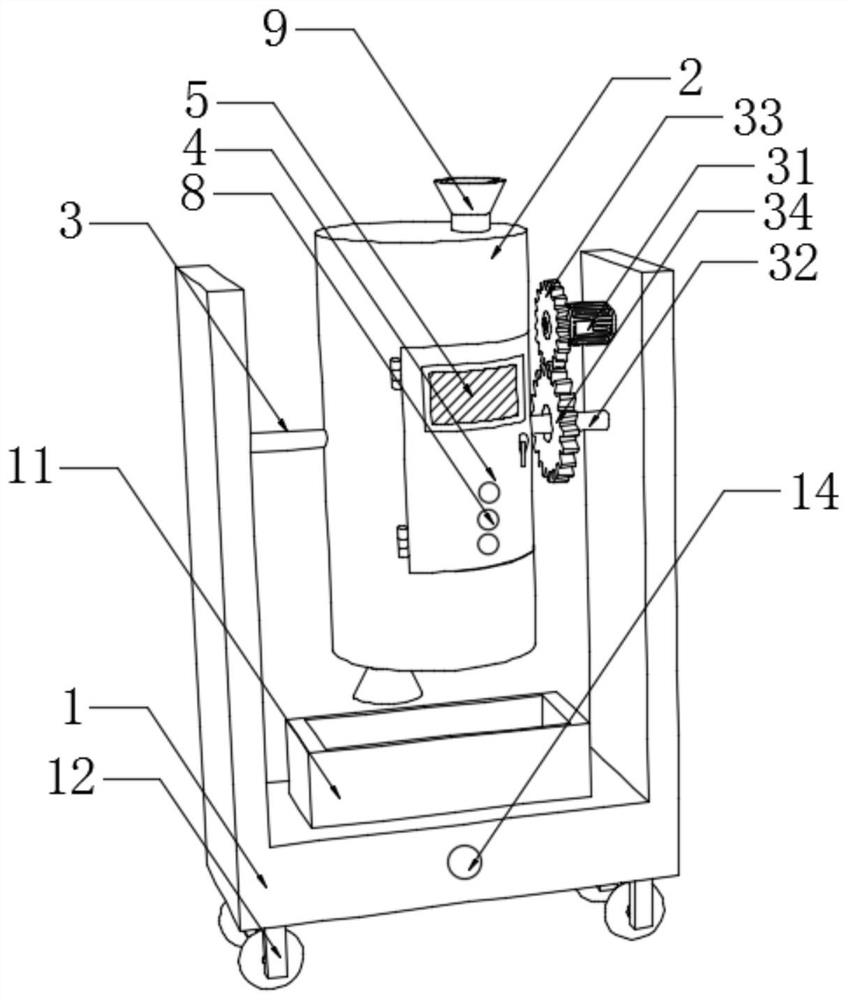

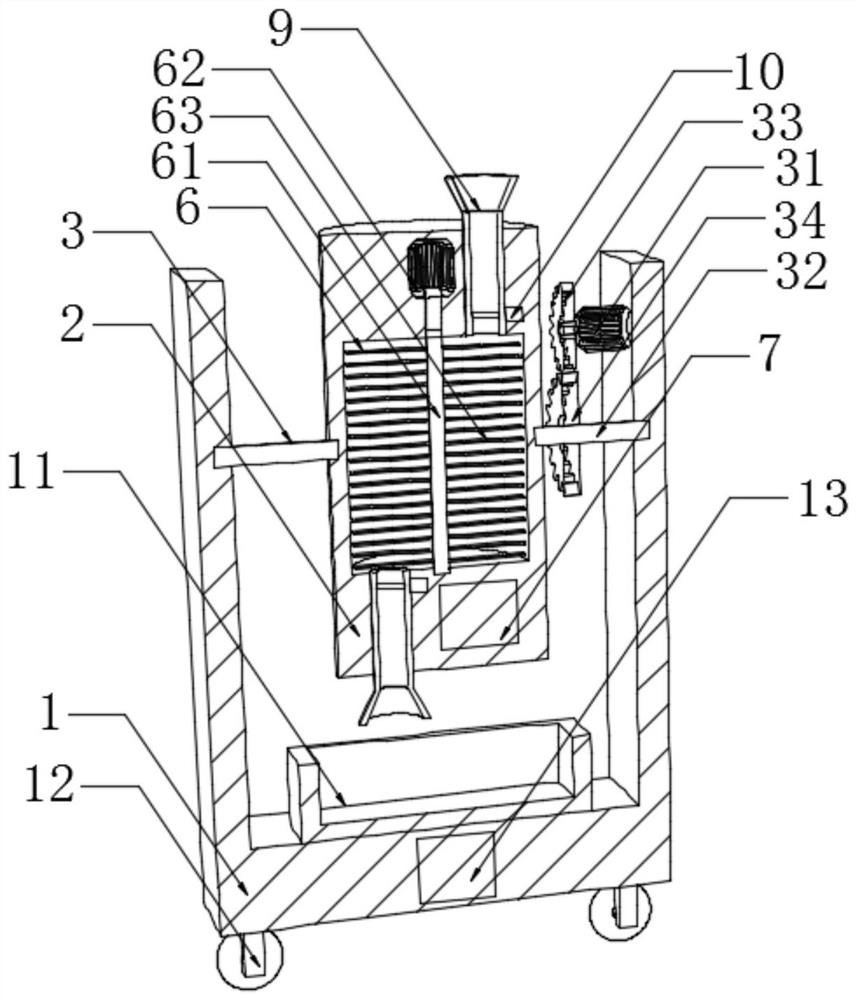

[0021] see Figure 1-4 , the present invention provides a multiple crushing device for plastic granular materials, including a U-shaped frame 1 and a cylinder body 2, the cylinder body 2 is arranged inside the U-shaped frame 1, and the top of the inner wall of the U-shaped frame 1 is provided with an angle adjustment assembly 3. There is a crushing assembly 6 inside the cylinder body 2, the top side of the cylinder body 2 and the other side of the bottom end are fixedly connected with the inlet and outlet hoppers 9, and the middle part of the bottom end of the inner wall of the U-shaped frame 1 is fixedly provided with a material storage box 11, The four corners at the bottom of the U-shaped frame 1 are fixed with universal wheels 12;

[0022] The sides of the cylinder body 2 are hinged with a sealing inspection and cleaning door 4 through two hinges, and the top of the sealing inspection and cleaning door 4 is fixedly provided with an observation window 5 .

Embodiment 2

[0024] The angle adjustment assembly 3 includes a servo motor 31 and two supporting shafts 32, the servo motor 31 is fixedly arranged on the top of one side of the inner wall of the U-shaped frame 1, and the two supporting shafts 32 are respectively fixedly arranged One end of the support shaft 32 is respectively connected with the tops on both sides of the inner wall of the U-shaped frame 1 through rotation, and one of the support shafts 32 is arranged on the bottom of the servo motor 31, and the output shaft of the servo motor 31 is fixedly sleeved with a pinion 33, one of which supports The fixed sleeve on the shaft 32 is provided with a large gear 34 meshing with the pinion 33;

[0025] A lithium battery 13 is fixedly embedded in the middle of the bottom end of the U-shaped frame 1;

[0026] The bottom of the side of the U-shaped frame 1 is fixed with an angle adjustment switch button 14, and the servo motor 31 is electrically connected to the lithium battery 13 through th...

Embodiment 3

[0029] The crushing assembly 6 includes an installation shaft 61 and a drive motor 62, the installation shaft 61 is rotatably arranged inside the cylinder body 2, the drive motor 62 is fixedly embedded in the middle part of the top of the cylinder body 2 inner wall, the output shaft of the drive motor 62 and the installation shaft 61 The top is fixedly connected, and the middle part of the installation shaft 61 is fixedly provided with several crushing blades 63;

[0030] Electromagnetic valves 10 are fixed on the two inlet and outlet hoppers 9, and a battery 7 is fixedly embedded on the bottom of one side of the cylinder body 2;

[0031] The bottom of the sealed inspection and cleaning door 4 is fixed with three processing switch buttons 8, and the drive motor 62 and the two solenoid valves 10 are electrically connected to the battery 7 through the three processing switch buttons 8 respectively;

[0032] Specifically, such as figure 1 , figure 2 , image 3 As shown, at fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com