Plate levelness detection device for mechanical manufacturing

A technology of mechanical manufacturing and detection device, applied in the field of plate levelness detection device, can solve problems such as troublesome operation process, and achieve the effect of avoiding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

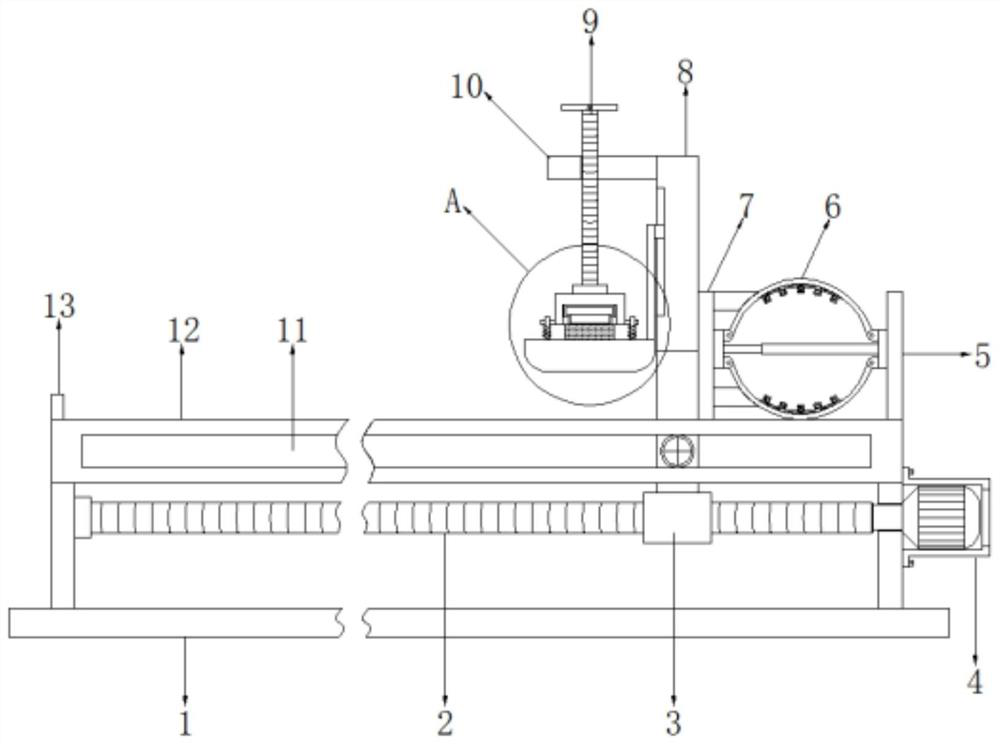

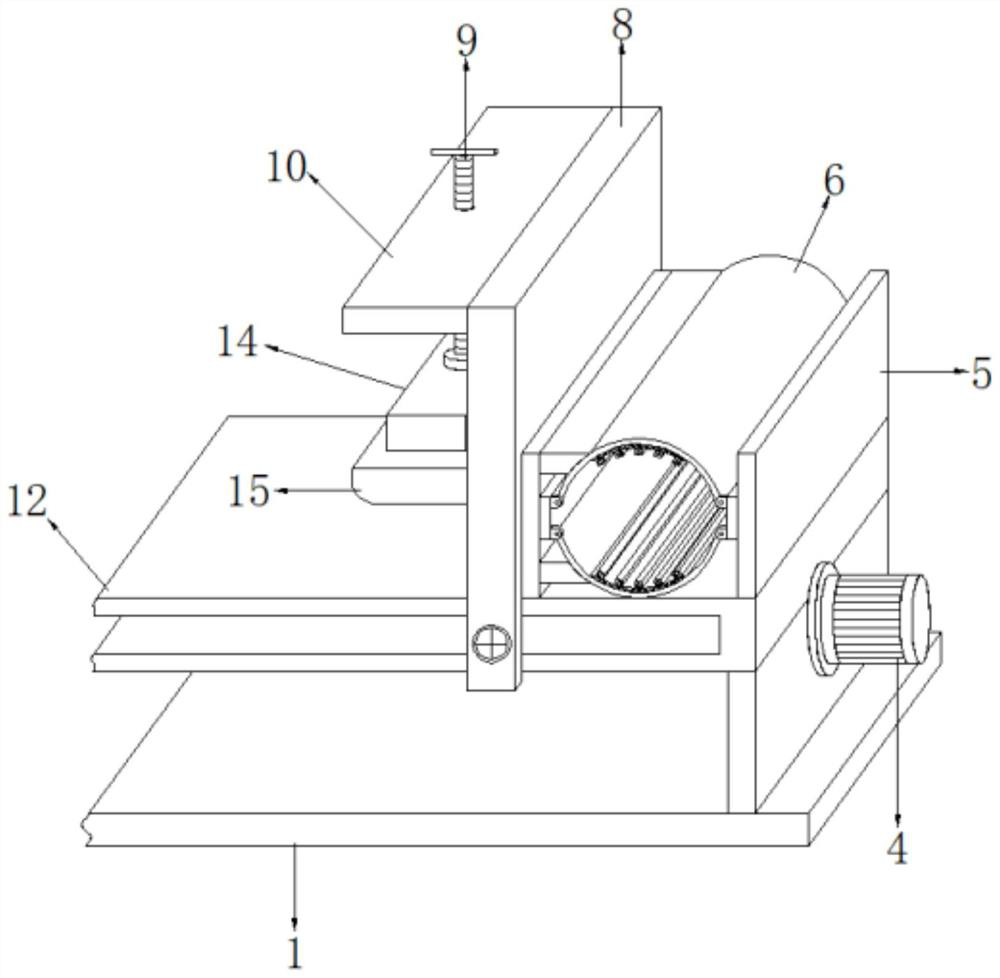

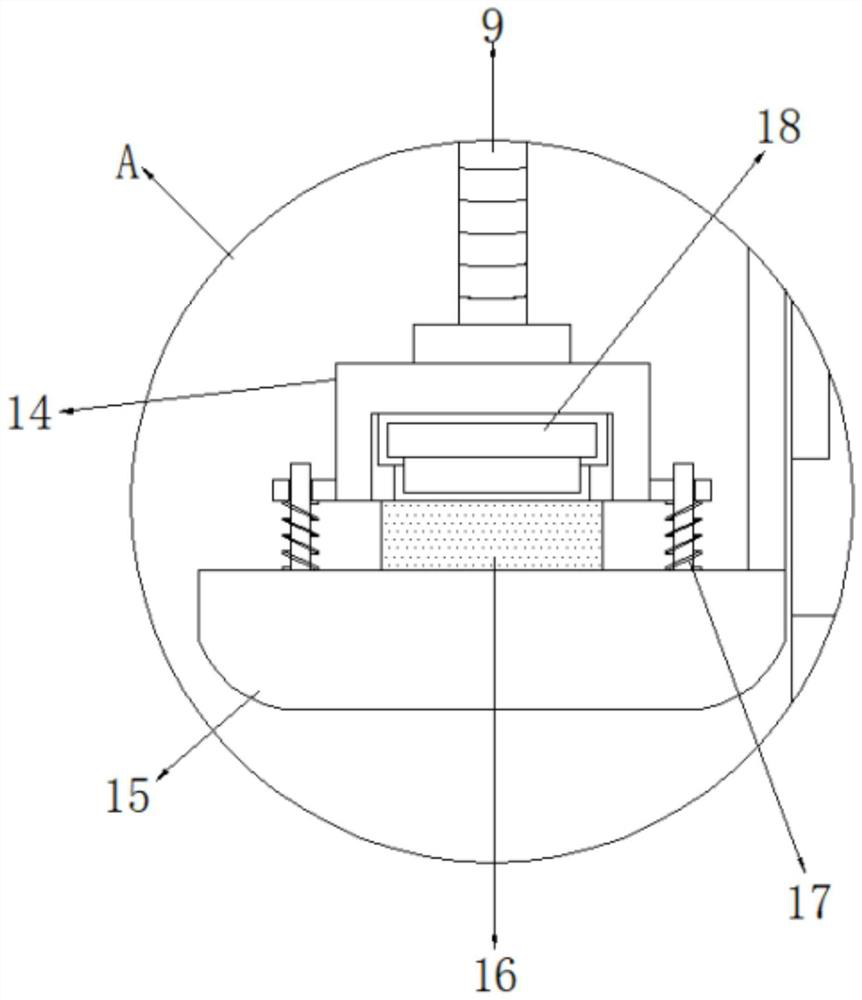

[0031] refer to Figure 1-5 , a plate levelness detection device for mechanical manufacturing, comprising a support platform 12, the outer wall of the support platform 12 is sleeved with a movable plate 8, and a top plate 10 is welded on the top of one side of the movable plate 8, and the top of the top plate 10 is There is a threaded hole on the side, and the inner wall of the threaded hole is threadedly connected with a threaded rod 9. The bottom of the threaded rod 9 is set as a detection mechanism. Plate 13, a clamping plate 7 is placed on one side of the top of the support platform 12, and a side of the clamping plate 7 and a side of the fixed plate 5 are welded with a connecting seat 19, and a side top of the connecting seat 19 and a U-shaped seats 20 are welded between the side bottoms, and steel sheets 6 are connected between the inner walls on both sides of the corresponding U-shaped seats 20 through pin shaft rotation, and rubber pads are welded in the middle of the ...

Embodiment 2

[0041] refer to Image 6 , a plate levelness detection device for mechanical manufacturing. Compared with Embodiment 1, this embodiment replaces the forward and reverse motor 4 and the threaded screw 2 with a hydraulic cylinder 28 and a connecting rod 29, and the hydraulic cylinder 28 It is connected to one side of the support plate by bolts, and the connecting rod 29 is connected between the piston end of the hydraulic cylinder 28 and one side of the movable sleeve 3 by bolts.

[0042] Working principle: Connect the hydraulic cylinder 28 to the hydraulic system, directly use the hydraulic cylinder 28 to adjust the position of the connecting rod 29 and the movable sleeve 3, so that the movable plate 8 moves on the support table 12, replacing the forward and reverse motor 4 and the threaded screw 2 Displacement operation, to avoid the impact of vibration generated when the forward and reverse motor 4 is working, and to maintain the stability of the movement of the movable plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com