Data conversion method based on pipeline three-dimensional model

A 3D model and pipeline technology, applied in the field of data conversion, can solve the problems of inconsistency in ISO drawings output by SPOOLGEN, increased workload, etc., and achieve the effect of improving design efficiency, improving consistency, and solving communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the examples.

[0022] The data conversion method based on the pipeline three-dimensional model of the present invention comprises the following steps:

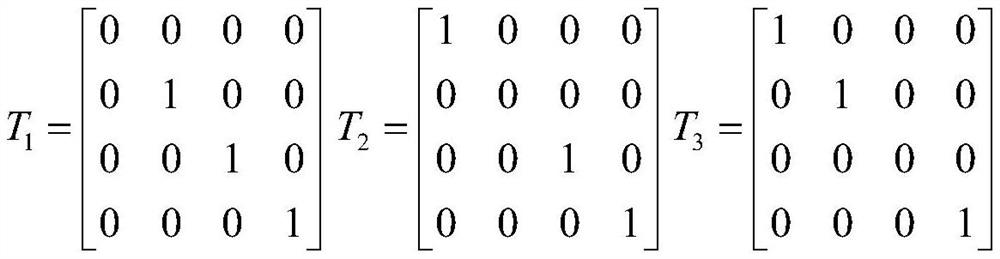

[0023] Step 1. Project the three-dimensional model of the pipeline in the E3D software to the YOZ plane along the X-axis direction of the model coordinate system in the E3D to a two-dimensional figure (using the projection transformation matrix T 1 ), recorded as group A graphics and saved as A.drw file, and projected to the XOZ plane along the Y-axis direction of the model coordinate system in E3D as two-dimensional graphics (using the projection transformation matrix T 2 ), recorded as group B graphics and saved as B.drw file, projected along the Z-axis direction of the model coordinate system in E3D to the XOY plane as two-dimensional graphics (using the projection transformation matrix T 3 ), recorded as group C graphics and saved as C.drw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com