Magnetic regulation and control wire stripping device for communication cable

A communication cable and wire stripping device technology, which is applied in the direction of circuits, electrical components, recycling technology, etc., can solve the problems of low flexibility, inconvenient operation, etc., and achieve the effects of reducing wear, convenient operation, and convenient stripping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

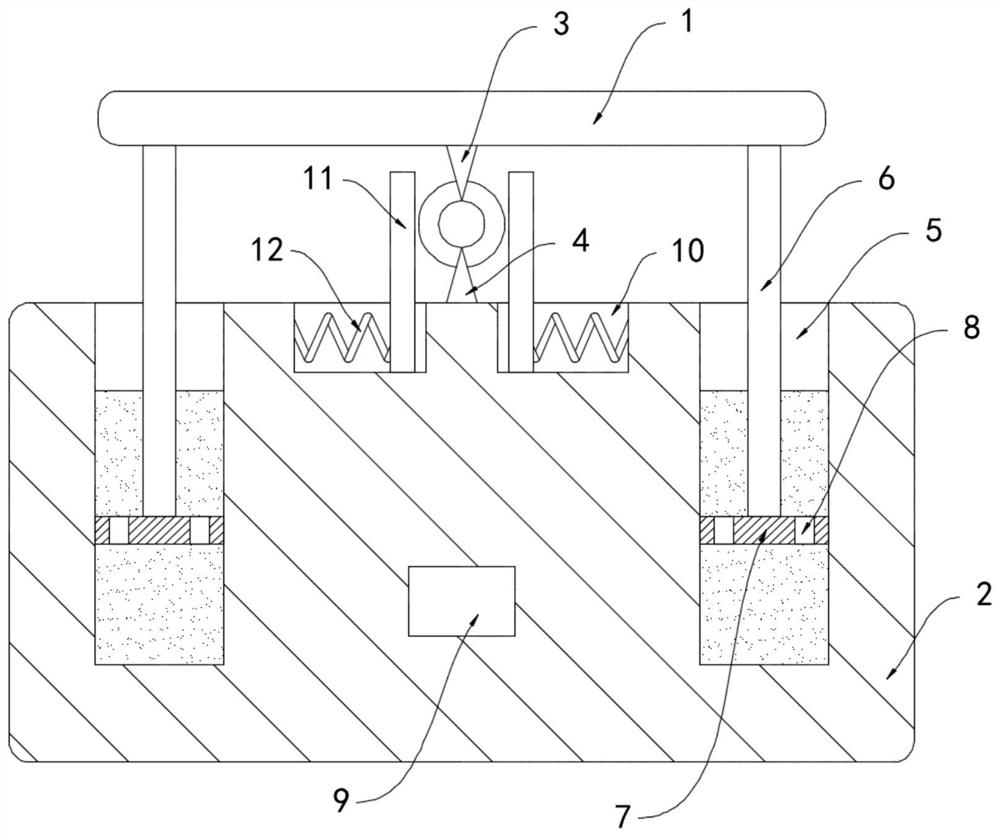

[0020] Such as figure 1 As shown, a magnetically controlled stripping device for communication cables includes an upper base 1 and a lower base 2, the upper base 1 and the lower base 2 are respectively equipped with a facing upper cutter 3 and a lower cutter 4, and the lower base 2 There are two chutes 5 on the upper surface, and the chutes 5 are filled with magnetorheological fluid, which is a mixture of tiny soft magnetic particles with high magnetic permeability and low magnetic hysteresis and non-magnetic permeable liquid. Suspension, the lower surface of the upper substrate 1 is fixedly connected with two sliding rods 6 matching the chute 5, and the lower end of the sliding rods 6 is fixedly connected with a lifting plate 7, and a plurality of guide holes 8 are arranged in the lifting plate 7, and the lifting The plate 7 is slidingly connected to the side wall of the chute 5, and the lower base 2 is provided with a storage battery 9, and the two ends of the storage batter...

Embodiment 2

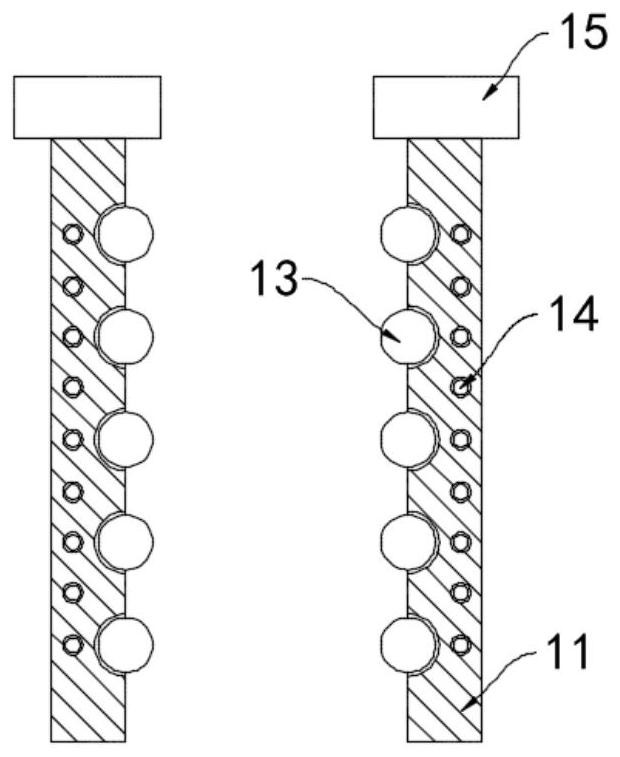

[0025] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a plurality of balls 13 are embedded on the opposite side walls of the two limiting plates 11, the balls 13 are made of permanent magnets, and the limiting plates 11 are embedded with The closed coil 14 is helically wound and the winding direction is perpendicular to the rolling direction of the ball 13 . An electromagnet 15 is installed on the upper end of the limit plate 11 , and the electromagnet 15 is coupled to both ends of the closed coil 14 .

[0026] In this embodiment, when the communication cable slides between the two limiting plates 11, the balls 13 can roll freely on the limiting plates 11, reducing the wear on the surface of the communication cable and the limiting plates 11, and the communication cable during stripping. The ball 13 is driven to roll, and the closed coil 14 continuously cuts the magnetic lines of the ball 13 to generate an induced current, which sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com