A kind of foam mattress production method

A production method and sponge technology, applied in the field of mattresses, can solve problems such as lack of air circulation, affecting sleep and human health, and waste cannot be dissipated in time, so as to achieve the effect of comfortable sleeping experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

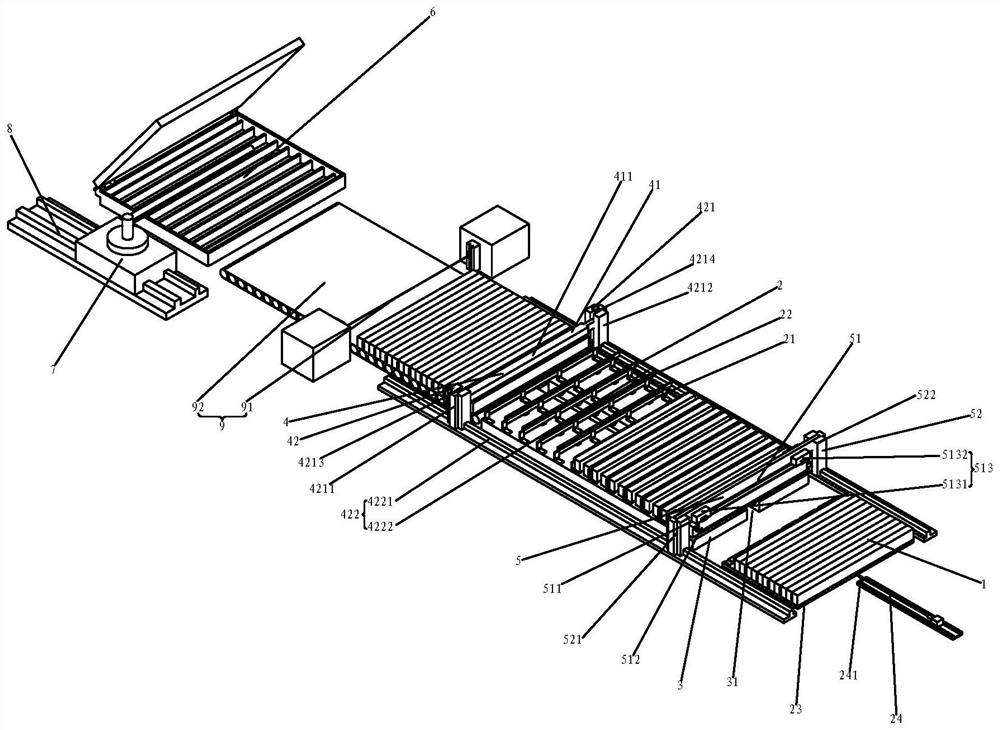

[0088] like Figure 1 to Figure 8 As shown, a method for producing a sponge mattress of the present invention comprises the following steps:

[0089] (1) Process the sponge mattress 1;

[0090] (2) processing the sponge mattress 1 into a plurality of sponge monomers 11;

[0091] (3) Assembling the sponge monomer 11 on the heat sink 2;

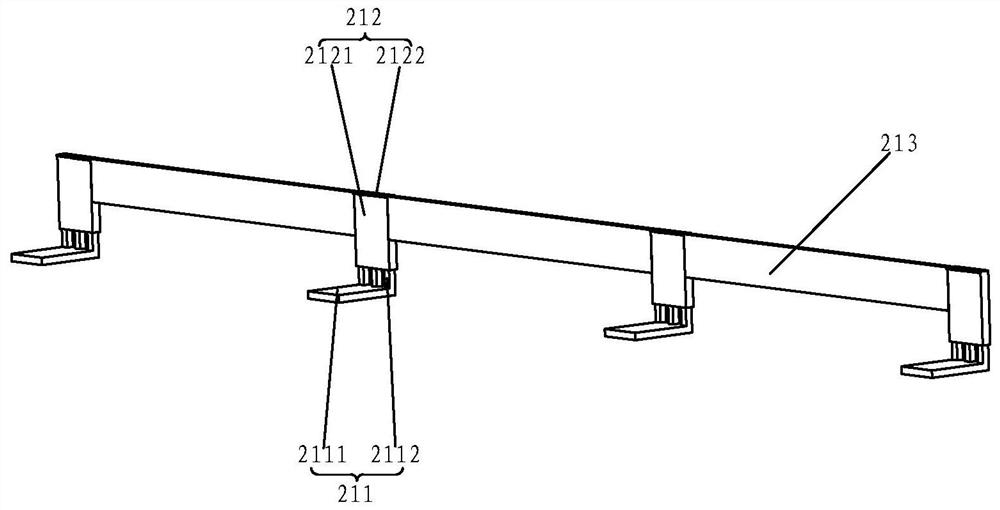

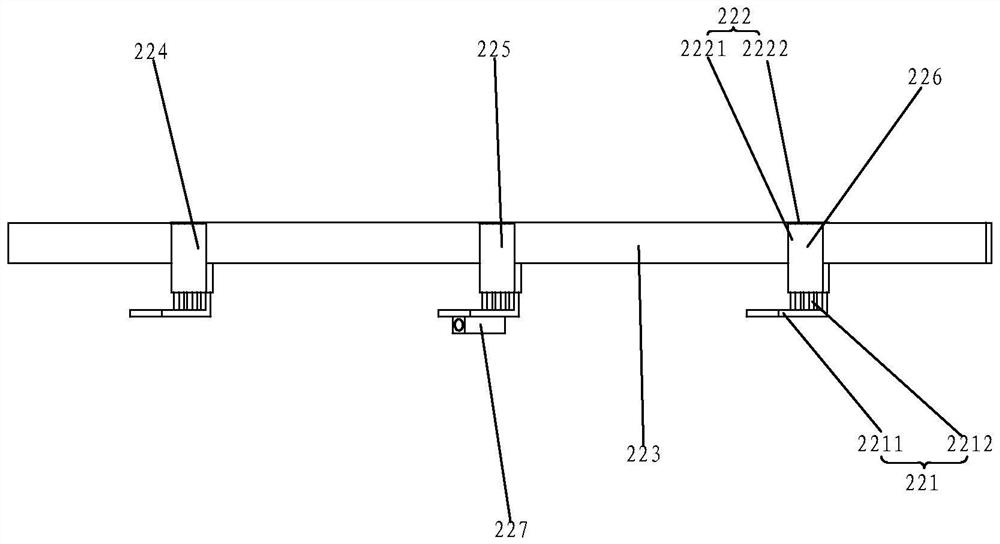

[0092] In step (3), the heat dissipation device 2 includes a plurality of fixing parts 21 that carry the sponge cells 11 and fix the sponge cells 11 , and the plurality of supporting the sponge cells 11 and drive the sponge cells 11 to the adjacent fixing parts 21 moves the extruded sliding part 22 , and the heat sink 23 that assembles the fixed part 21 and the sliding part 22 .

[0093]In this way, after the foam mattress 1 is processed into a plurality of foam cells 11, each foam cell 11 is ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com