Gas transfer type stamping lower die easy to demold

A transfer type, easy demoulding technology, applied in the field of stamping dies, can solve the problems of small distance between stamping parts and the inner wall of the cavity, affecting the overall efficiency of stamping, and difficulty in demoulding, so as to reduce the difficulty of demoulding, not easy to skew, and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

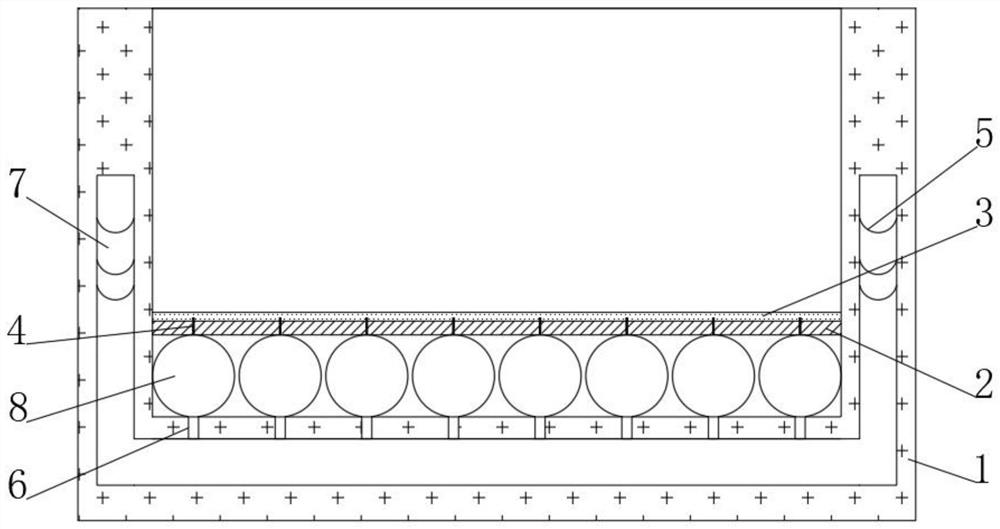

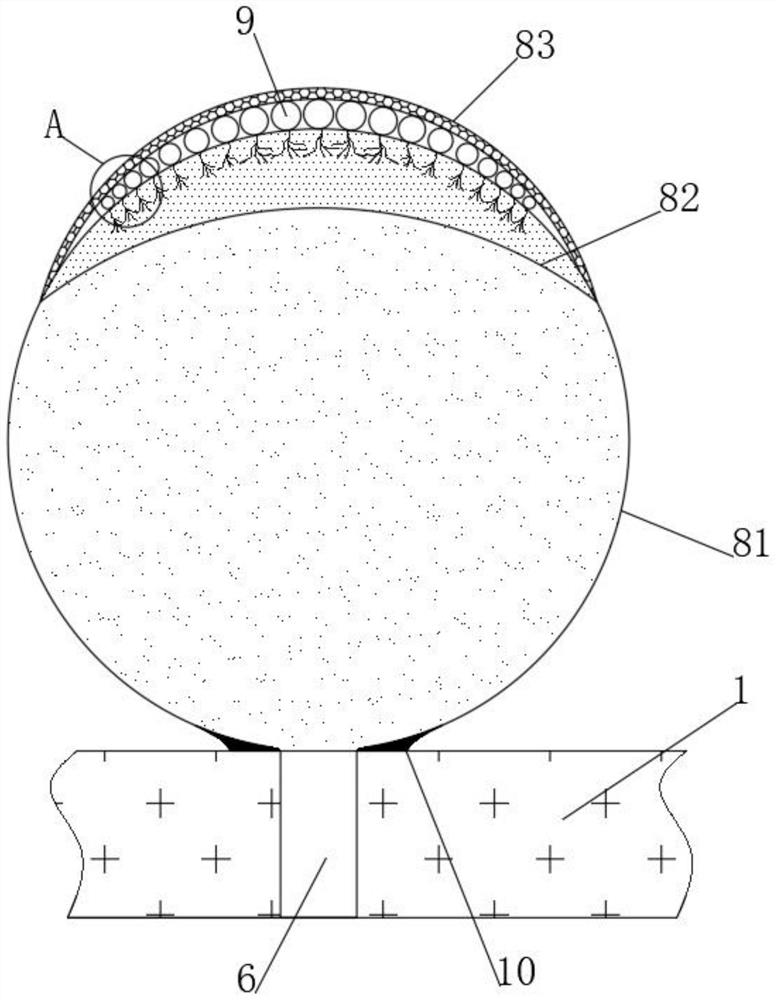

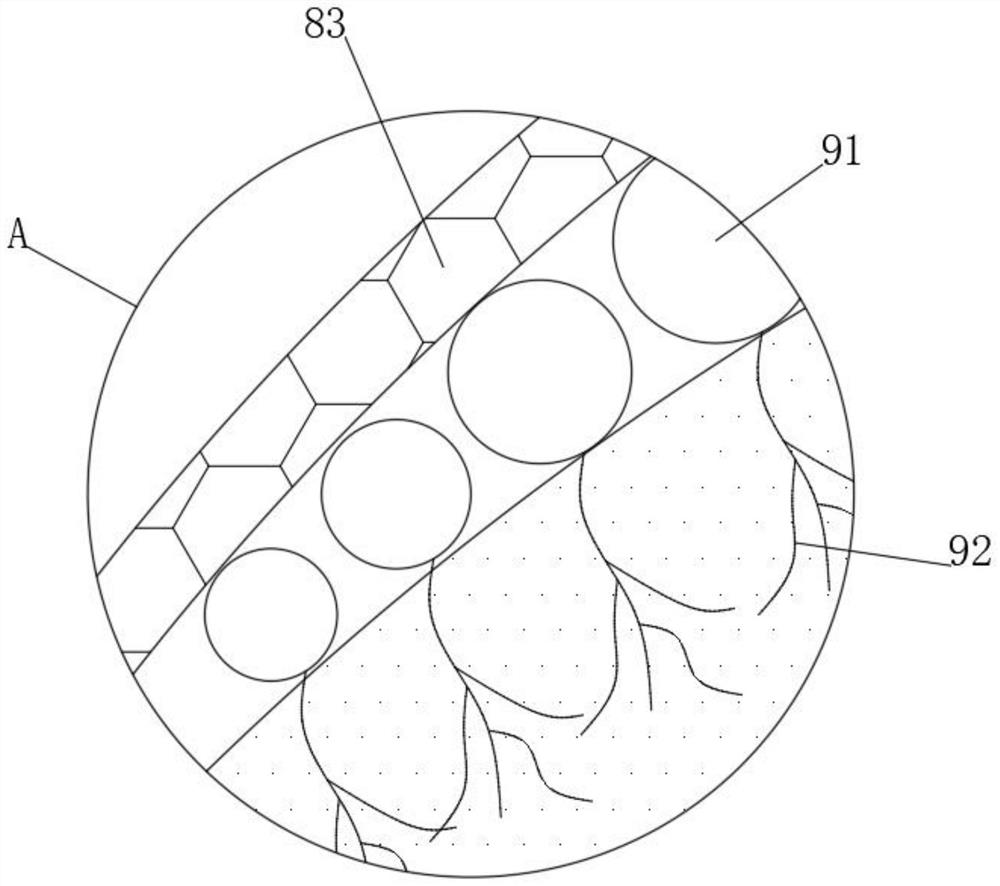

[0045] see figure 1 , a stamping lower mold with air transfer type and easy demoulding, comprising a lower mold body 1, an air removal cavity 7 is excavated inside the bottom of the lower mold body 1, and a plurality of inner push shrapnels 5 are fixedly connected to the inner wall above the air removal cavity 7, The cross-section of the inner push shrapnel 5 is a downwardly concave structure, and the distance between a plurality of inner push shrapnels 5 gradually decreases from top to bottom. When the inert gas is transferred into the gas removal chamber 7, the inner push shrapnel 5 deforms upward , after the stamping is completed, the extrusion effect of the punch is lost, and at this time, the inner pushing shrapnel 5 resumes deformation, thereby accelerating the transfer of the inert gas to the inner balloon 8, thereby making the bearing plate 2 return to its original position faster, In turn, the speed of jacking up the stamping parts is faster, thereby reducing the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com