Clamp for sewing machine shell machining

A sewing machine and casing technology, applied in the field of fixtures for sewing machine casing processing, can solve the problems of low production efficiency and high labor intensity of workers, and achieve the effects of improving processing quality, clamping quality, and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

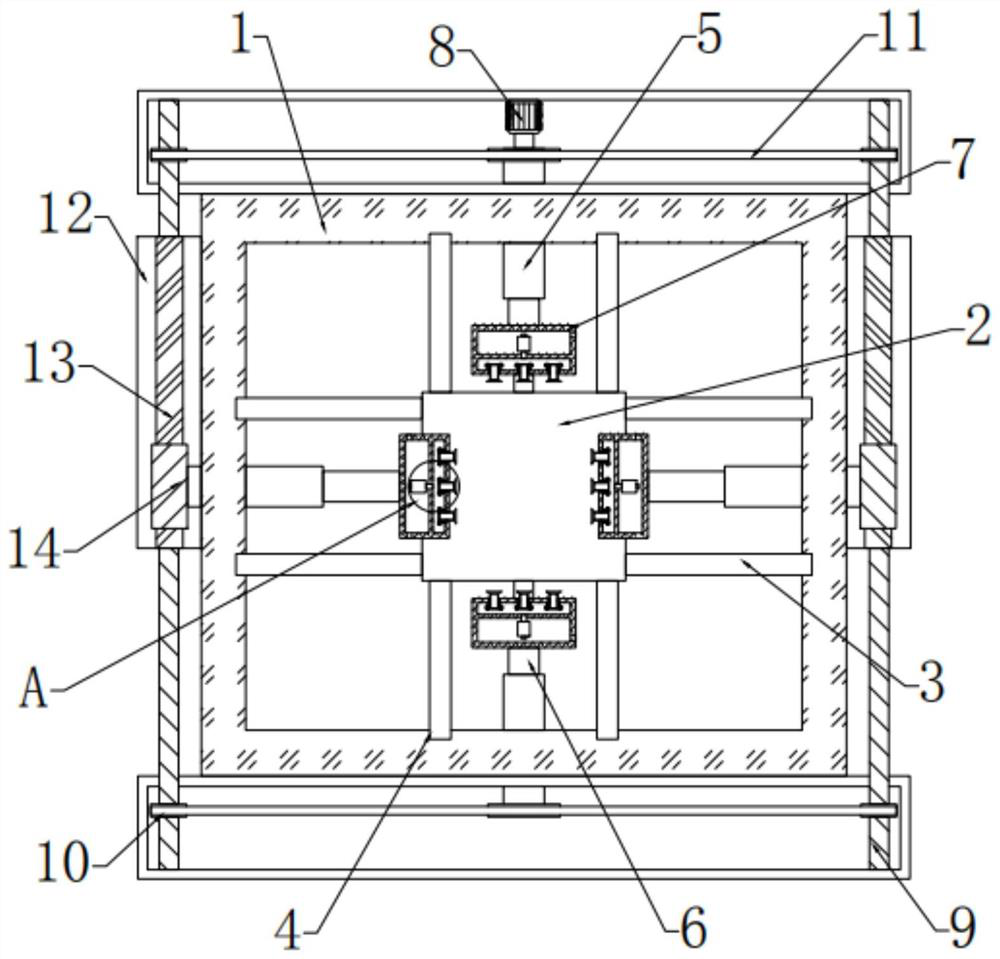

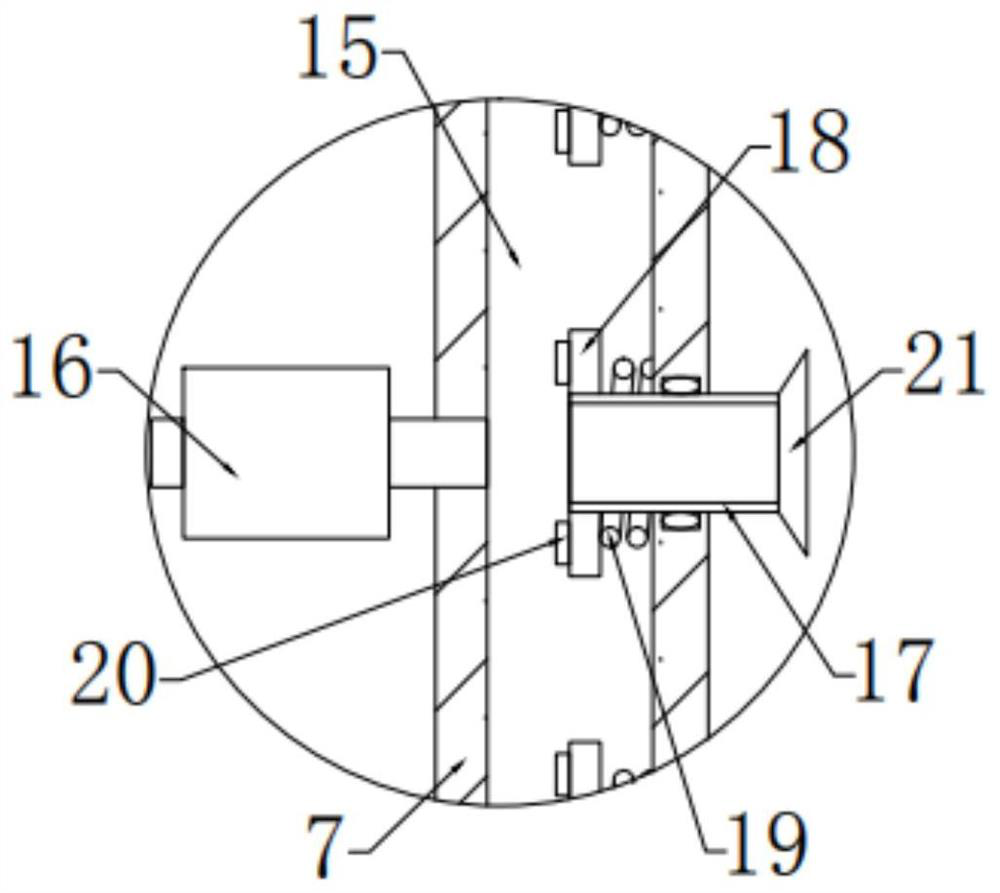

[0025] see Figure 1-4 , in an embodiment of the present invention, a clamp for sewing machine shell processing, including a processing table 1, the inner side of the processing table 1 is provided with a support mechanism for placing the shell, and the upper side of the support mechanism is provided with a clamp for fixing the shell Clamping mechanism, the clamping mechanism is connected with the driving mechanism arranged on the outside of the processing table 1.

Embodiment 2

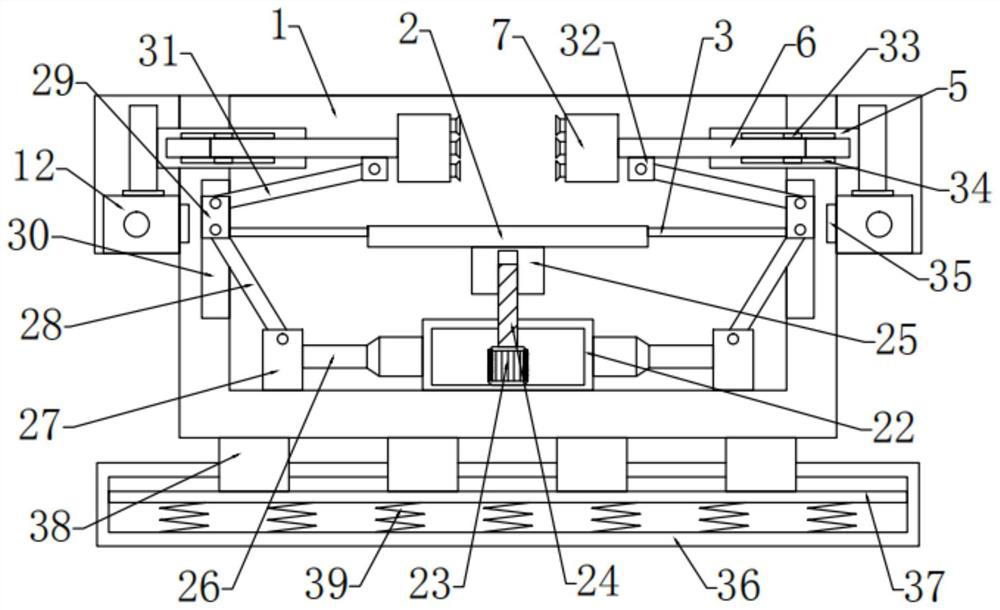

[0027] In this embodiment, the support mechanism includes a fixed block 22 fixedly connected to the inner bottom of the processing table 1, and the inner side of the fixed block 22 is bolt-connected with a second motor 23, and the output end of the second motor 23 is connected to the second The threaded rod 24 is connected, and the second threaded rod 24 is screwed with the fixed rod 25 fixedly connected to the bottom of the placement plate 2. The placement plate 2 is arranged on the upper side of the fixed block 2, and the outer side of the placement plate 2 is fixedly connected. There are several limit rods 3, and the limit rods 3 are slidably connected with the guide groove 4 arranged on the inner side of the processing table 1. By setting the supporting mechanism, it is convenient for people to take and place the shell.

[0028] In this embodiment, the clamping mechanism includes telescopic rods 26 that are fixedly connected to the four sides of the fixed block 22. block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com