Electric impact wrench with current PID control

An electric impact wrench and electric current technology, applied in the direction of wrenches, motor tools, manufacturing tools, etc., can solve the problems of bolt loosening and falling off, bolt damage, etc., and achieve the effect of high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better illustrate the technical solutions and innovative features of the present invention, the present invention will be further described below in combination with the accompanying drawings and embodiments.

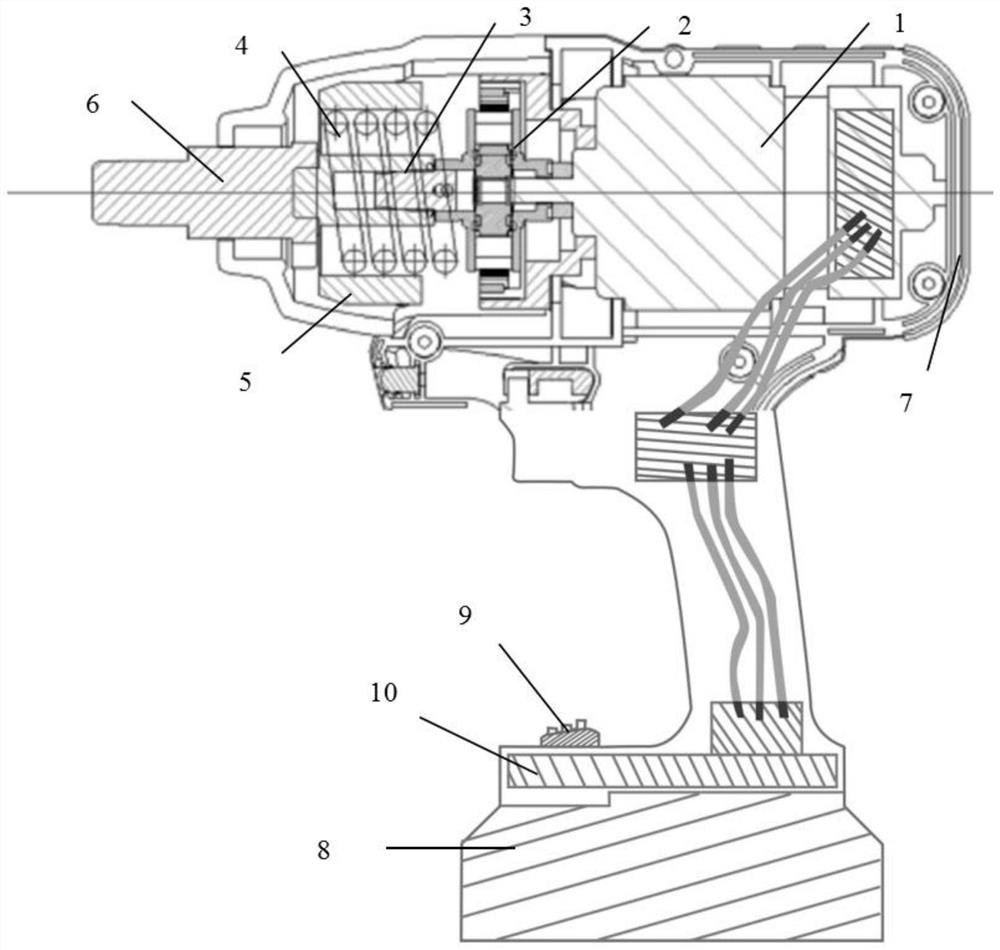

[0025] Such as figure 1 As shown, an electric impact wrench controlled by current PID includes a brushless DC motor 1, a planetary gear reducer 2, a main shaft 3, a main pressure spring 4, an active block 5, a driven block 6, a casing 7, a power supply 8, Display device 9 and control system 10 . The kinetic energy generated by the brushless DC motor 1 built into the wrench is partially transformed into the kinetic energy driving the active block 5 to rotate through the planetary gear reducer 2, and partially transformed into the potential energy compressed and stored by the main pressure spring 4, and part of the energy is converted into thermal energy and mechanical loss. The form disappears. The potential energy stored in the compression of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com