Automatic composite wallboard production device

A production device and composite wallboard technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems affecting the quality and uneven density of composite wallboards, and achieve the effects of avoiding air bubbles and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

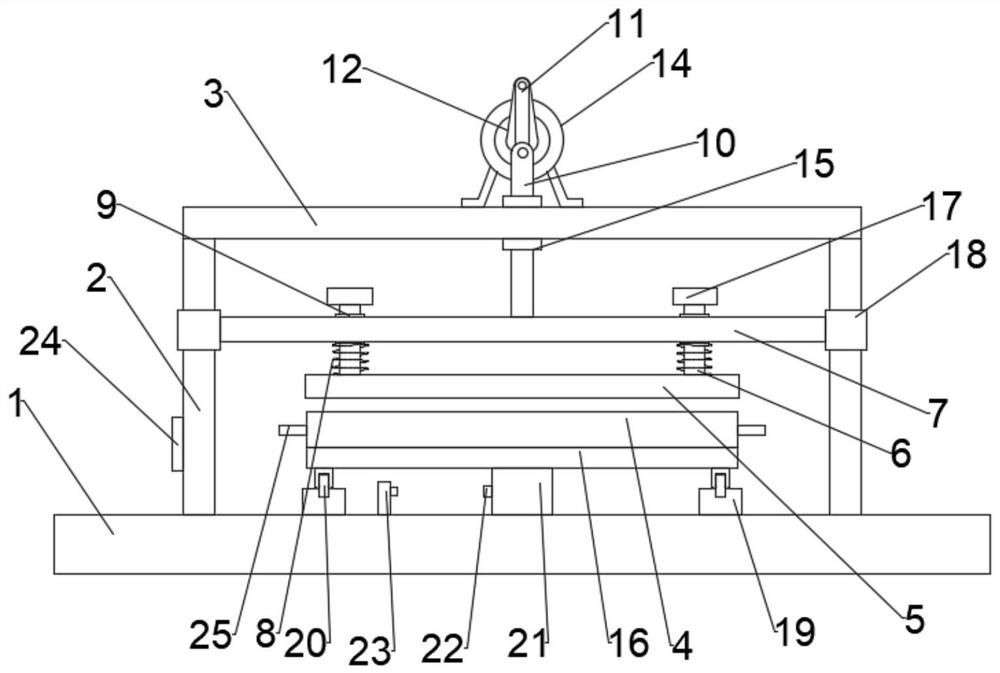

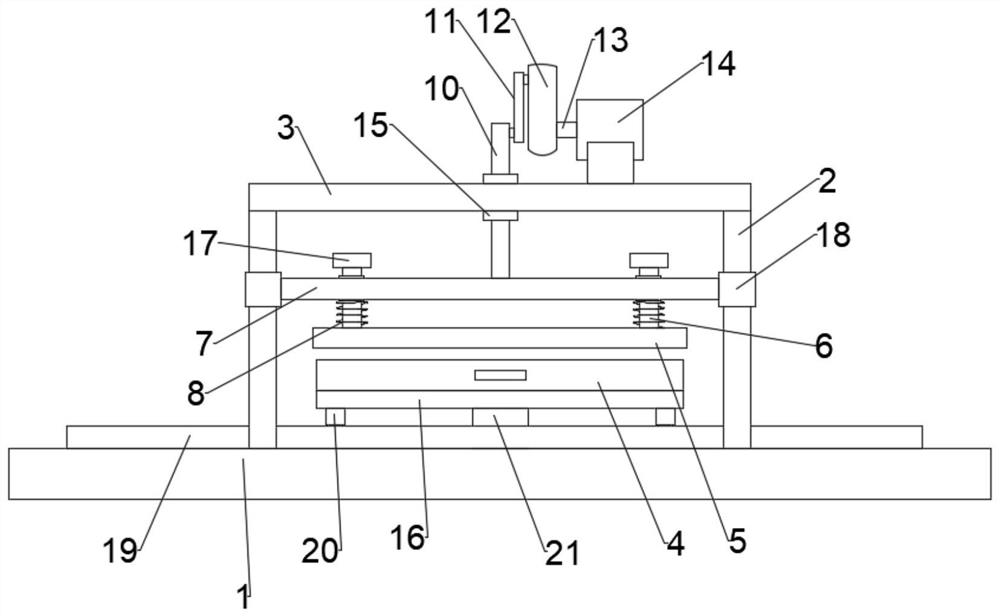

[0023] combine Figure 1-2 , an automatic composite wall panel production device, comprising a base 1, four support columns 2, a mounting plate 3 and a mold box 4, four support columns 2 are fixed on the upper end of the base 1, and the upper ends of the four support columns 2 are installed There is a mounting plate 3, the mold box 4 is arranged above the base 1, a motor 14 is installed on the upper end of the mounting plate 3, a rotating shaft 13 is installed on the output end of the motor 14, and a cam 12 is installed on the rotating shaft 13, so The front side of the cam 12 is rotatably connected with a second connecting rod 11 through a pin shaft, and the front side of the second connecting rod 11 is connected with a moving rod 10 through a pin shaft rotating shaft 13, and the moving rod 10 penetrates the mounting plate 3 and is connected with the mounting plate. 3 Sliding fit, the lower end of the moving rod 10 is fixed with a moving plate 7, and four first connecting rod...

Embodiment 2

[0030] combine Figure 1-4 , an automatic composite wallboard production device, this embodiment further defines the present invention on the basis of embodiment 1.

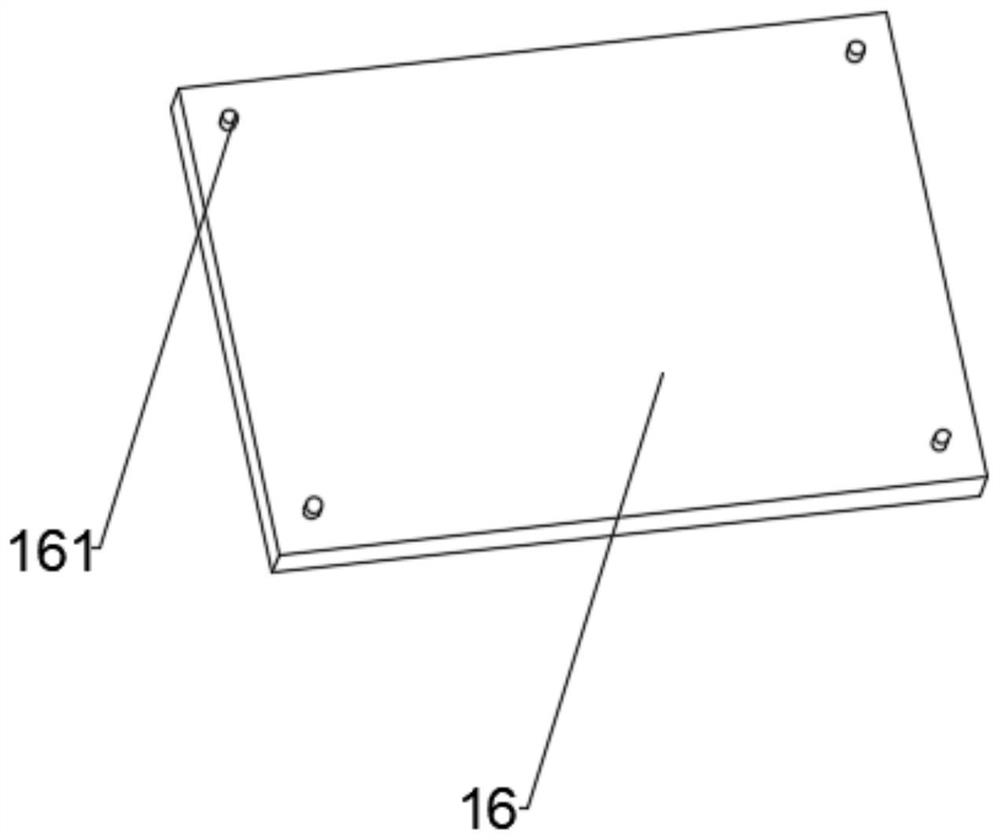

[0031] The lower end of the mold box 4 is connected with a supporting plate 16, the lower end of the supporting plate 16 is equipped with a driving device 21, the four corners of the lower end of the supporting plate 16 are equipped with rollers 20, the upper end of the base 1 is provided with a guide rail 19, and the rollers 20 and the guide rail 19 are rolled and matched, and an infrared receiver 22 is arranged on one side of the driving device 21, an infrared emitter 23 is installed on the upper end of the base 1, and a controller 24 is installed on the support column 2 on the front side. The controller 24 is wirelessly connected with the driving device 21 and the infrared receiver 22 .

[0032] Specifically, by setting the supporting plate 16 and the lower end of the supporting plate 16 is equipped with a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com