Pouring method of concrete floors in housing construction

A pouring method and concrete technology, which are applied in the field of housing construction, can solve the problems of long concrete setting time and easy formation of construction joints, and achieve the effects of avoiding indwelling construction joints, connecting evenly and densely, and shortening the setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

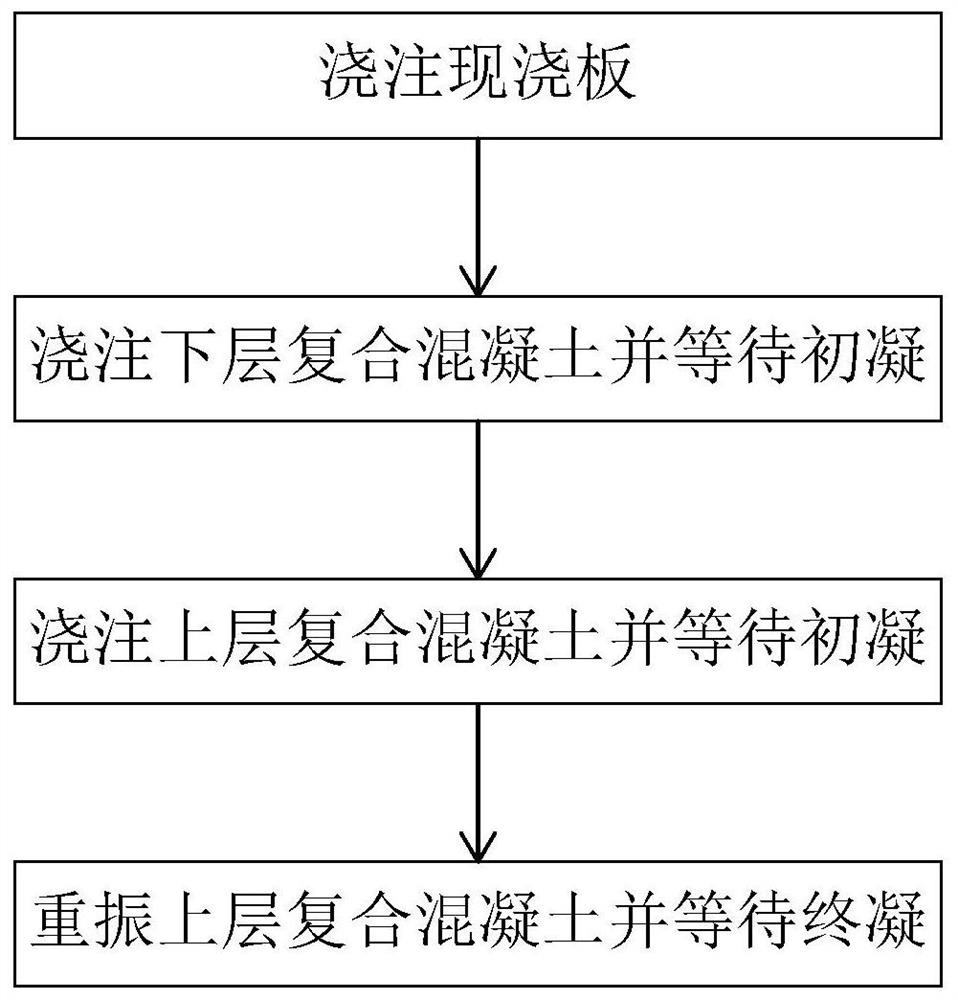

[0023] refer to figure 1 , which is a method for pouring concrete floor slabs for house construction disclosed by the present invention, comprising the following steps,

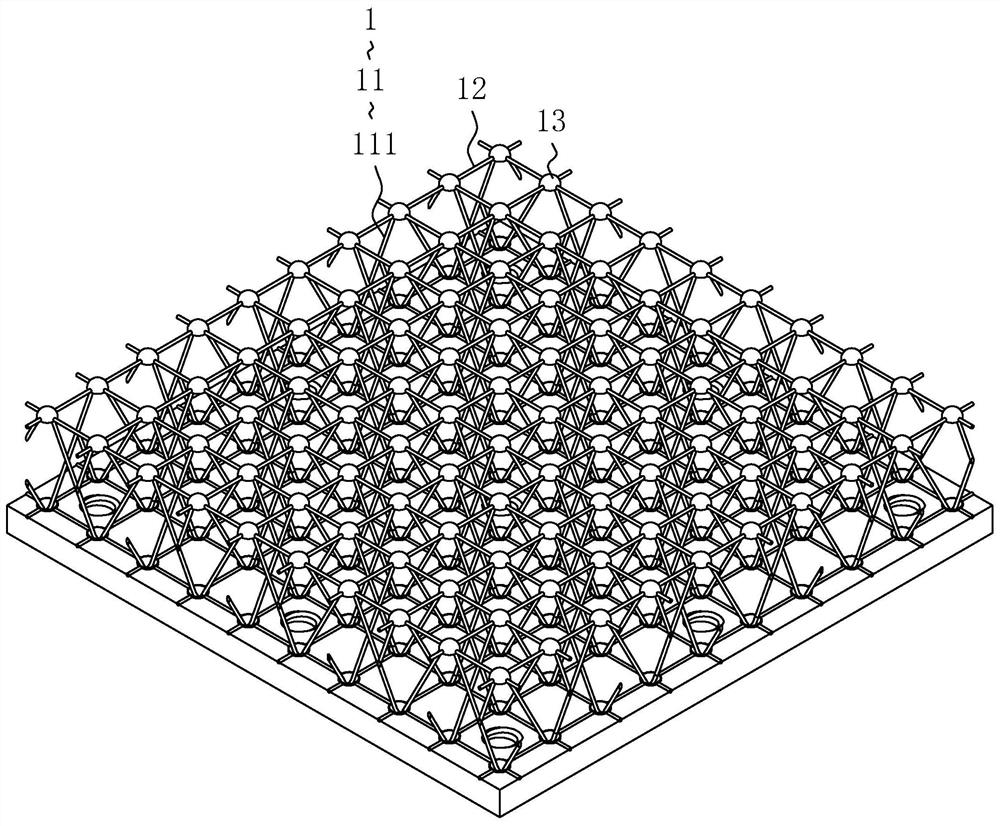

[0024] S1 prefabricated reinforcement mesh 11 component 1, prepare 1500 parts of Portland concrete, mix 1000 parts of composite concrete;

[0025] S2 First place the bottom plate with mesh grooves on the vibrating table, then place the prefabricated mesh 11 component 1 on the bottom plate and fit it with the mesh groove, and wrap around the mesh 11 component 1 Formwork, then pour the Portland concrete into the cavity formed by the formwork, and stop pouring when the Portland concrete submerges the formwork to three-fifths of the height and is lower than the upper steel mesh 12 of the reinforcement mesh 11 component 1;

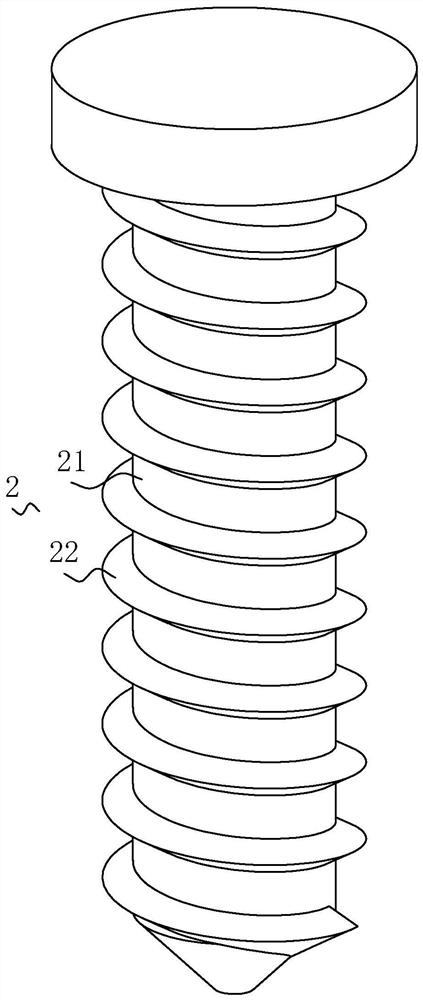

[0026] S3 Insert a plurality of embedded parts 2 into the opening of the reinforcement mesh 11 assembly 1, and make the lower end of the embedded parts 2 collide with the bottom plate, and fi...

Embodiment 2

[0037] Embodiment 2: A pouring method for a concrete floor slab for building construction. The difference from Embodiment 1 is that the components and parts by weight in the composite concrete are shown in Table 1.

Embodiment 3

[0038] Embodiment 3: A pouring method for a concrete floor slab for building construction. The difference from Embodiment 1 is that the components and parts by weight in the composite concrete are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com