Glass substrate jacking mechanism

A glass substrate and jacking mechanism technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of glass substrate movement, force concentration of glass substrate, friction damage, etc., to avoid friction damage, avoid position movement, improve The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

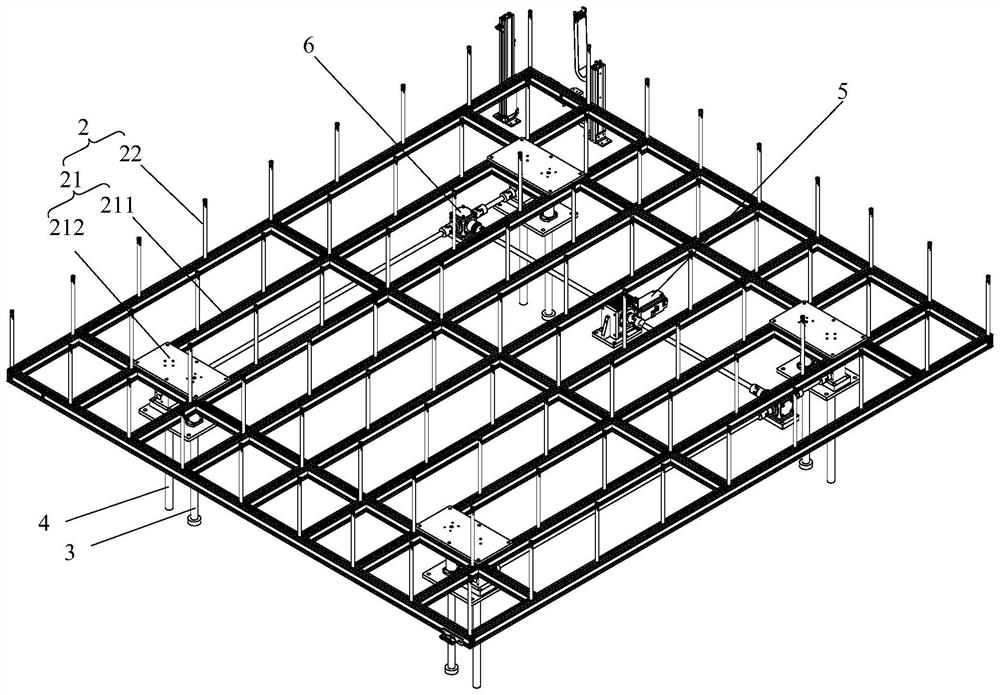

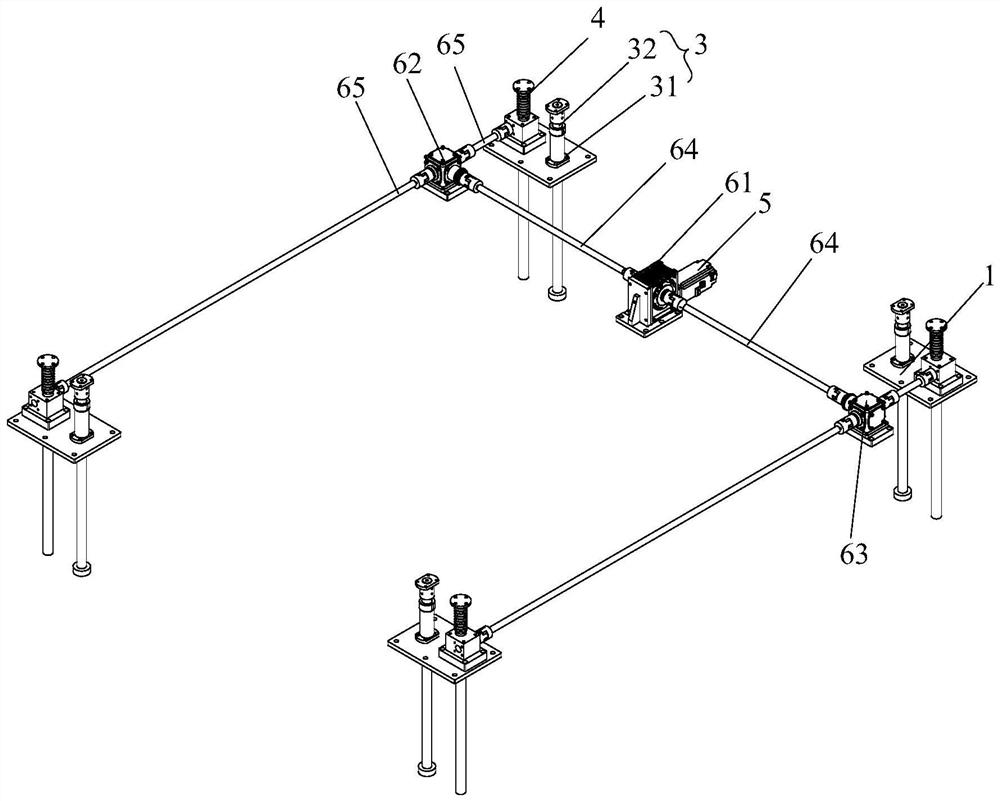

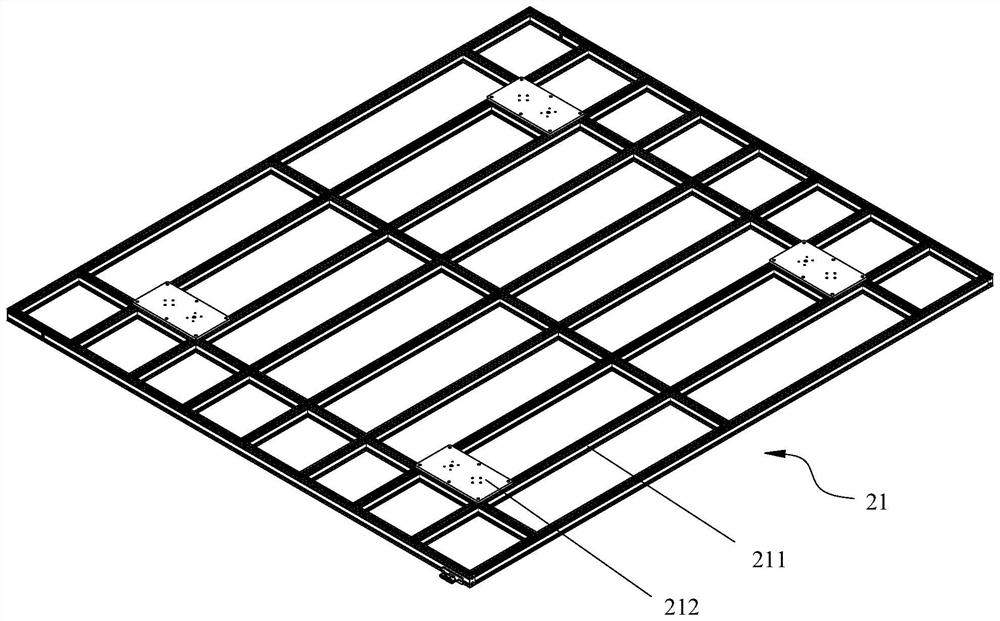

[0050] This embodiment provides a glass substrate lifting mechanism, which is especially suitable for lifting large-sized glass substrates. Specifically, such as Figure 1-4 As shown, the glass substrate lifting mechanism includes a frame body, a support assembly 2, a guide assembly 3, a plurality of lifting rods 4, a driving source 5 and a transmission assembly 6, wherein the support assembly 2 is used to horizontally carry the glass substrate, and the guide assembly 3 The fixed end is set on the frame body, the movable end is connected with the support assembly 2, the fixed end is slidably matched with the movable end, a plurality of jacking rods 4 are arranged in parallel and respectively connected to the support assembly 2, the input of the driving source 5 and the transmission assembly 6 The transmission assembly 6 includes a plurality of output ends, and the plurality of output ends are connected to the plurality of jacking rods 4 in a one-to-one correspondence, and can ...

Embodiment 2

[0061] The difference between this embodiment and the first embodiment is that the second transmission shaft 65 is not connected to the corresponding jacking rod 4 through a gear set. Specifically, the jacking rod 4 is provided with a rack portion extending in the vertical direction, and the transmission assembly 6 also includes four spur gears, which are respectively connected to the other four second transmission shafts 65 in one-to-one correspondence. At one end (that is, the end not connected with the T-shaped spiral bevel gear commutator), the four spur gears mesh with the four rack parts in one-to-one correspondence. In this embodiment, through the cooperation of the gear and the rack portion of the jacking rod 4, the rotational movement of the second transmission shaft 65 along the horizontal axis is converted into the linear motion of the jacking rod 4 in the vertical direction, the structure is simpler, and it is beneficial to reduce the overall The cost of the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com