Pouring device for alkyd resin production and processing

An alkyd resin and filling box technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve problems such as position movement, and achieve the effect of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

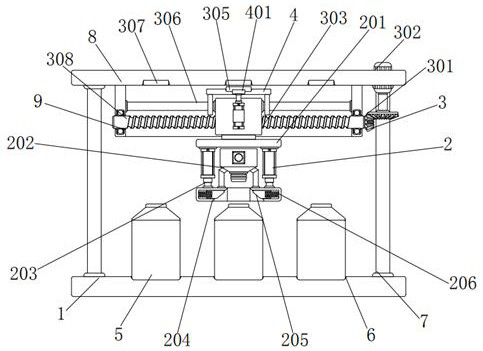

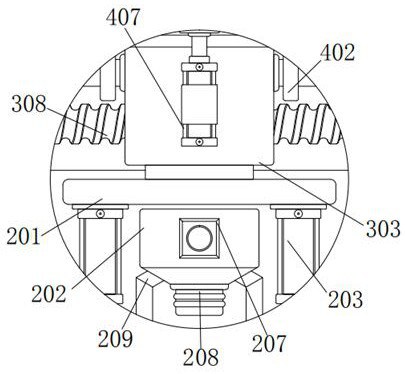

[0031] A pouring device for the production and processing of alkyd resin, including a bottom plate 1, a column 7 and a top plate 8, the four inner corners of the bottom plate 1 and the top plate 8 are fixedly connected with the columns 7, and the bottom plate 1 can be supported by the column 7 and the top plate 8 The lower end of the top plate 8 is fixedly connected with a pinch plate 9, and a drive assembly 3 is arranged inside the bottom of the pinch plate 9. The drive assembly 3 includes a first bevel gear 301, a motor 302, a slider 303, a first rotating shaft 304, an induction block 305, Guide rail 306, displacement sensor 307, threaded rod 308 and second bevel gear 309, motor 302 is affixed inside the right end of pinch plate 9, the model of motor 302 is the servo motor of MR-J2S-10A, the output shaft of motor 302 is affixed There is a first rotating shaft 304, the output shaft of the motor 302 can drive the threaded rod 308 to rotate through the first bevel gear 301 and t...

Embodiment 2

[0033] As an option, see figure 1 , 3, 4 and 5, the perfusion device used for the production and processing of alkyd resin, the lower end of the slider 303 is provided with a perfusion assembly 2, the perfusion assembly 2 includes a first horizontal plate 201, a perfusion box 202, an electric push rod 203, a second horizontal Plate 204, clamping block 205, spring 206, feed pipe 207, pouring port 208 and support 209, the first horizontal plate 201 is fixed on the lower end of slider 303, and slider 303 can drive the first horizontal plate 201 to move, the second The left and right sides of the lower end of a horizontal plate 201 are fixedly connected with electric push rods 203, the electric push rod 203 can control the lifting of the second horizontal plate 204, and the lower end of the internal push rod of the electric push rod 203 is fixedly connected with the second horizontal plate 204, The inner side of the upper end of the second horizontal plate 204 is fixedly connecte...

Embodiment 3

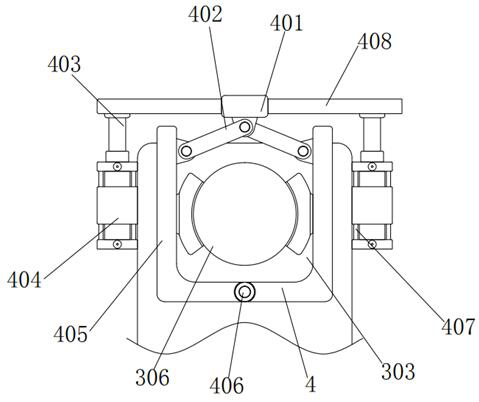

[0036] As an option, see Figure 1-4 , used for the perfusion device used in the production and processing of alkyd resin, the left and right sides of the outer wall of the slider 303 are provided with a positioning assembly 4, the positioning assembly 4 includes a pad 401, a support rod 402, a hydraulic rod 403, a sleeve 404, a splint 405, The second rotating shaft 406, the hydraulic cylinder 407 and the third horizontal plate 408, and the multiple hydraulic cylinders 407 are respectively fixed on the front and rear sides of the outer wall of the slider 303 through the sleeve block 404. The model of the hydraulic cylinder 407 is HOB light hydraulic cylinder, hydraulic The interior of the cylinder 407 is connected with a hydraulic rod 403. The hydraulic rod 403 can move inside the hydraulic cylinder 407 and ensure relative sealing during the movement. The upper ends of the hydraulic rod 403 are fixedly connected with the third horizontal plate 408. The hydraulic rod 403 403 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com