High-voltage direct-current supporting capacitor shell accessory welding tool clamp

A welding jig and high-voltage DC technology, applied in the field of welding jig, can solve the problems of single position limitation, poor position, unable to meet the welding requirements of lifting lug accessories, etc., and achieve the effect of preventing position movement and saving adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

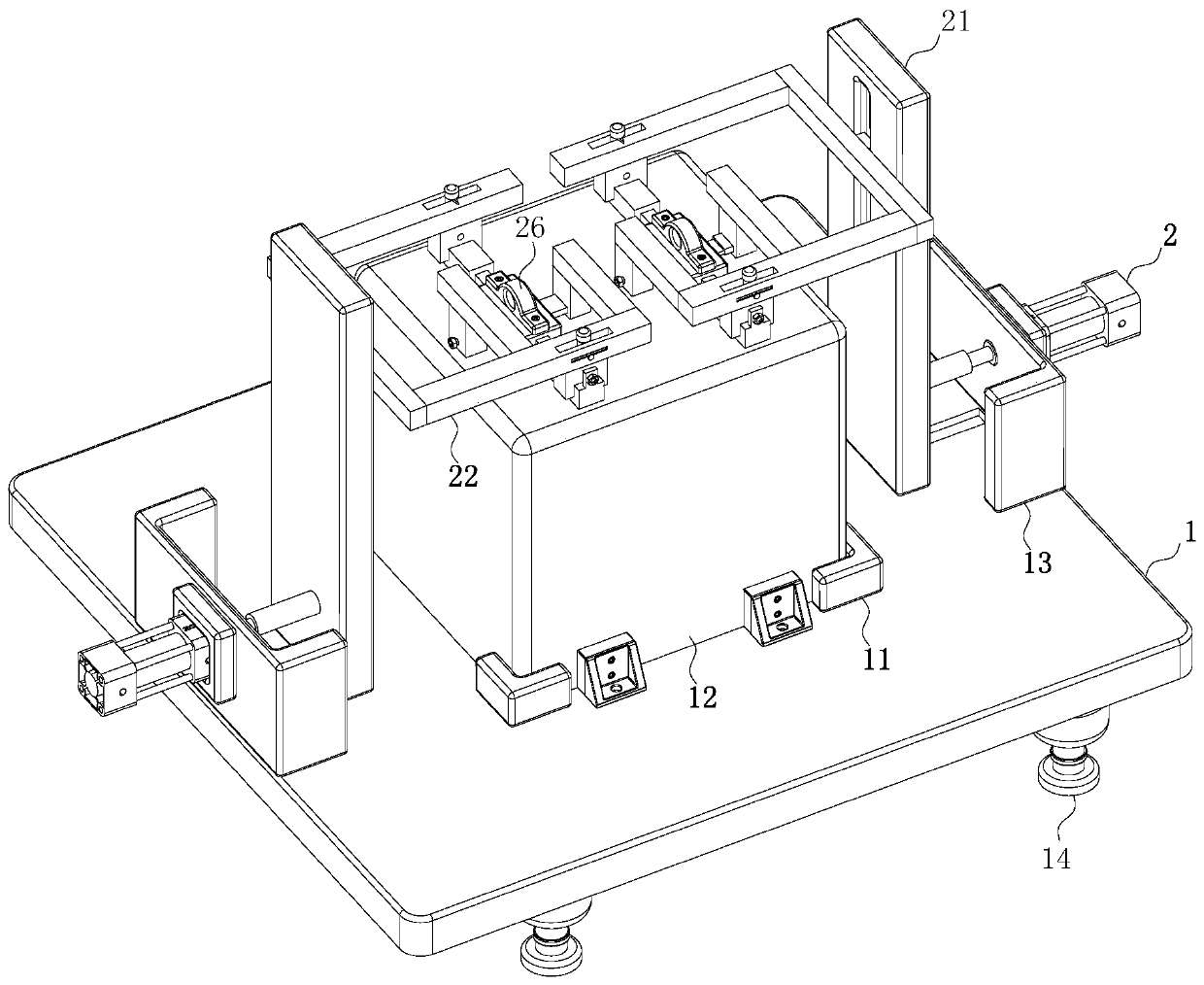

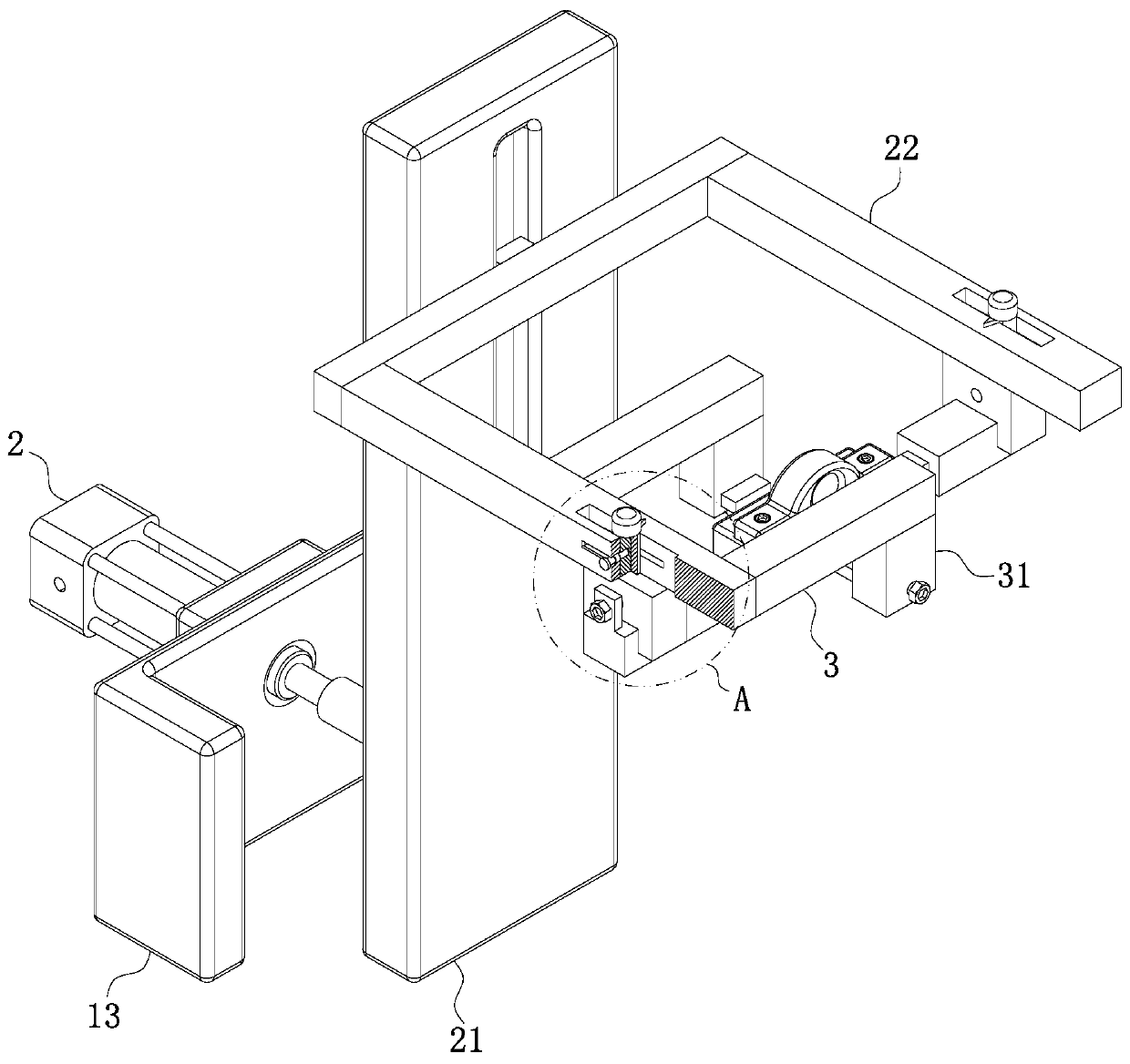

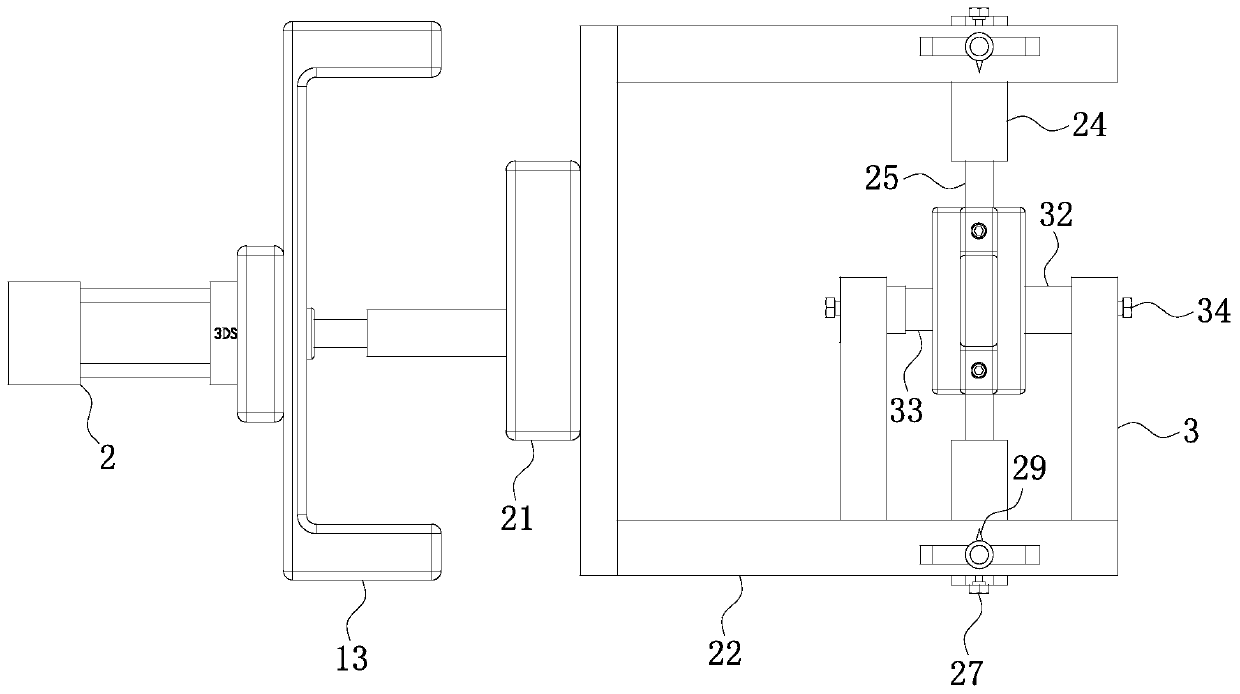

[0023] As an embodiment of the present invention, the lower surface of the base 1 is fixedly connected with evenly arranged support bases 14; When working, when the capacitor 12 needs to weld the lifting lug 26 accessories, in order to further improve the position accuracy of the lifting lug 26 welding, the support base 14 that is evenly arranged is fixed on the lower surface of the base 1, and then the support base 14 is placed on a relatively flat workbench, and then the adjusting ring is twisted manually or with a wrench, so that the adjusting ring is rotated up and down, and then the height of the support seat 14 is adjusted, so that the base 1 is completely horizontally placed, so it is effective This reduces the machining accuracy of the workbench and the accuracy requirements for horizontal placement, and further improves the accuracy of welding the lifting lug 26 on the surface of the capacitor 12 .

[0024] As an embodiment of the present invention, the first limit bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com