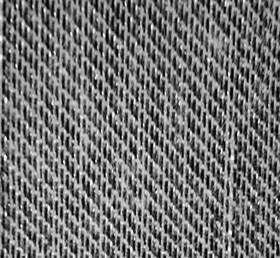

Weaving method of ribbon-like filament double-sided fabric

A technology of double-sided fabric and flat yarn, which is applied in the field of clothing fabric weaving, can solve the problems of many defects, and achieve the effect of not being easy to twist, reducing dark spots, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment includes the following steps:

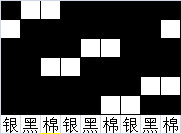

[0062] 1) Warping: Cotton yarn and flat yarn are warped separately; the flat yarn is warped as the lower weaving shaft, and the cotton yarn is warped for use; the cotton yarn warping speed is 200m / min, and the warping tension is 13g; the flat yarn warping speed is 10m / min, warping tension 35g;

[0063] 2) Cotton yarn sizing: the cotton yarn is sizing, sucking, and pressing, and then enters the dry splitting area to form an upper weaving shaft; the viscosity of the cotton fiber sizing tank is 8%, and the sizing rate is 9%; the size is polyvinyl alcohol 3g / L, starch 2.5g / L, acrylic acid 1g / L and water as solvent;

[0064] 3) Weaving: Air-jet upper and lower shaft looms are used for weaving. The upper loom and the lower loom are installed on the loom for drafting and weaving; Alternately pass through the split rods up and down; 3 split rods are arranged in parallel; the cross-section of the split rods is elliptical;

[0...

Embodiment 2

[0068] This embodiment includes the following steps:

[0069] 1) Warping: Cotton yarn and flat yarn are warped separately; the flat yarn is warped as the lower weaving shaft, and the cotton yarn is warped for use; the cotton yarn warping speed is 205m / min, and the warping tension is 12g; the flat yarn warping speed is 5 m / min, warping tension 34g;

[0070] 2) Cotton yarn sizing: After sizing, suction, and pressing, the cotton yarn enters the dry splitting area and is wound into an upper weaving shaft; the viscosity of the cotton fiber sizing tank is 6%, and the sizing rate is 8%; the size is polyvinyl alcohol 3g / L, starch 2.5g / L, acrylic acid 1g / L and water as solvent;

[0071] 3) Weaving: Air-jet upper and lower shaft looms are used for weaving. The upper loom and the lower loom are installed on the loom for drafting and weaving; Alternately pass through the split rods up and down; 4 split rods are arranged in parallel; the cross section of the split rods is circular;

...

Embodiment 3

[0075] This embodiment includes the following steps:

[0076] 1) Warping: Cotton yarn and flat yarn are warped separately; the flat yarn is warped as the lower weaving shaft, and the cotton yarn is warped as a spare; the cotton yarn warping speed is 190m / min, and the warping tension is 14g; the flat yarn warping speed is 10m / min, warping tension 32g;

[0077] 2) Cotton yarn sizing: After sizing, suction, and pressing, the cotton yarn enters the dry splitting area and is wound into an upper weaving shaft; the viscosity of the cotton fiber sizing tank is 7%, and the sizing rate is 8.6%; the size is polyvinyl alcohol 3g / L, starch 2.5g / L, acrylic acid 1g / L and water as solvent;

[0078] 3) Weaving: Air-jet upper and lower shaft looms are used for weaving. The upper loom and the lower loom are installed on the loom for drafting and weaving; Alternately pass through the split rods up and down; 3 split rods are arranged in parallel; the cross section of the split rods is circular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com