Valve chamber cover cap structure capable of avoiding lubricating oil impact

A valve chamber and lubricating oil technology, which is applied to engine components, machines/engines, housings, etc., can solve the problems of inability to buffer impact force, large destructive force of the rubber coating, and easy damage to the rubber coating, so as to increase the life and ease Effect of processing and weakening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

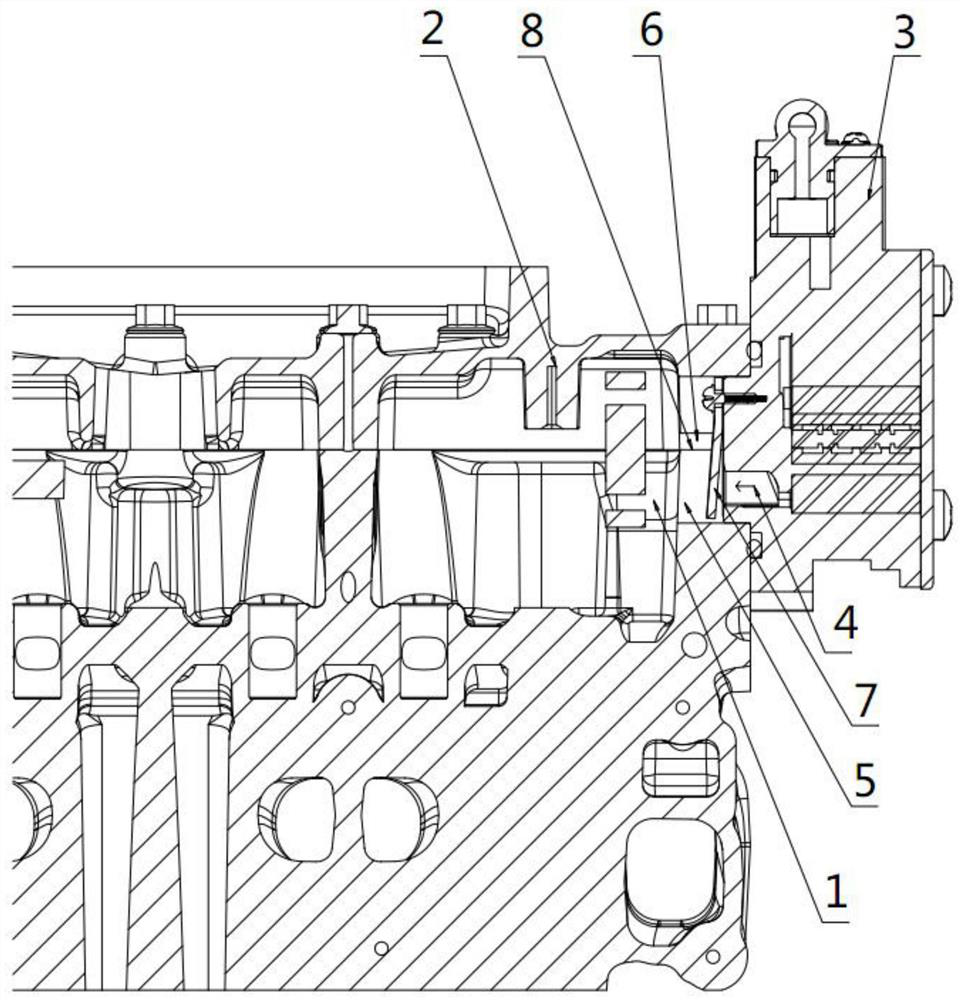

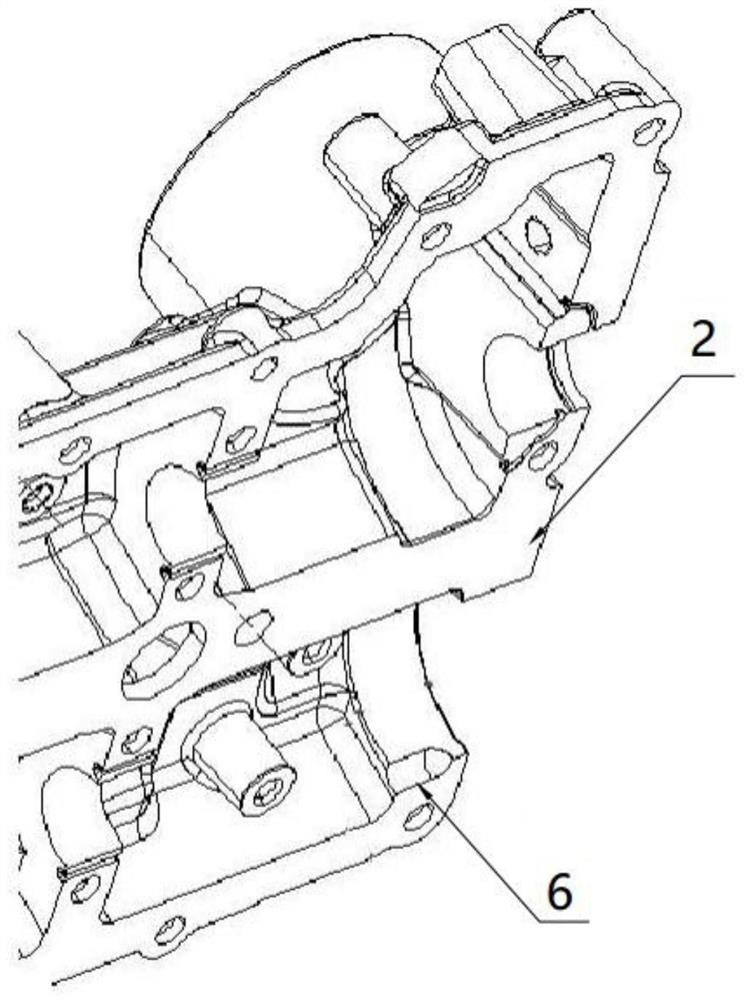

[0020] A valve chamber cover structure that avoids the impact of lubricating oil according to the specific implementation manner of this scheme, such as figure 1 , 3 As shown, it includes a valve chamber cover 2 covered on the upper end of the engine cylinder head 1, and the rear end surface of the valve chamber cover 2 is provided with an oil return port 5 connected to the oil outlet 4 of the vacuum pump 3. The oil outlet 4 extends into the oil return port 5 and enters the inner chamber of the valve chamber cover 2; an oil drain groove 6 is arranged on the inner edge of the bottom surface of the valve chamber cover 2 that cooperates with the engine cylinder head 1. The oil drain groove 6 is close to the oil return port 5 and extends along the direction of the oil outlet 4. The inner cavity of the oil drain groove 6 is an arc surface, and the inner side of the arc surface faces the valve chamber cover 2. Inner cavity; the oil return port 5 is provided with a blocking plate 7;...

Embodiment 2

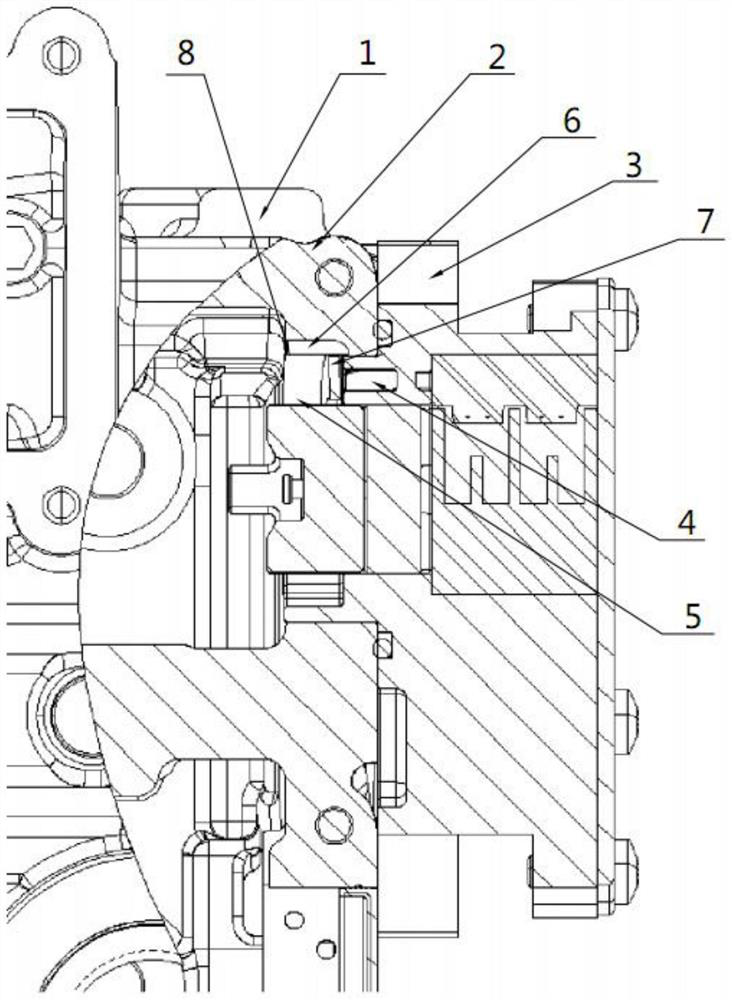

[0023] Such as figure 2 As shown, on the basis of Embodiment 1, one end of the oil drain groove 6 in this embodiment extends toward the oil return port 5 and at least partially surrounds the outer surface of the oil outlet 4 . When the engine starts to run, the engine oil flowing through the vacuum pump 3 comes out from the position of the baffle 7 and flows to the left and right sides. As the engine speed increases, the oil flow rate increases and the impact force becomes stronger. The piece 7 flows into the oil return port 5, a part of which is blocked by the baffle piece 7, rushes to the joint surface of the valve chamber cover 2 and the cylinder head, and washes the glue layer on the joint surface, and then flows into the oil return port 5. By extending the oil drain groove 6 to the periphery of the oil outlet 4, the impact of engine oil on the rubber coating layer 8 at the end of the oil outlet 4 is further reduced.

[0024] As a preferred technical solution of this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com