High-strength electromagnetic shielding and heat-conducting pbt/pet nanocomposite material and preparation method

A nanocomposite material and electromagnetic shielding technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, complicated preparation process, and large amount of fillers, etc., to achieve inhibition Agglomeration, reduce solvent usage, improve dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

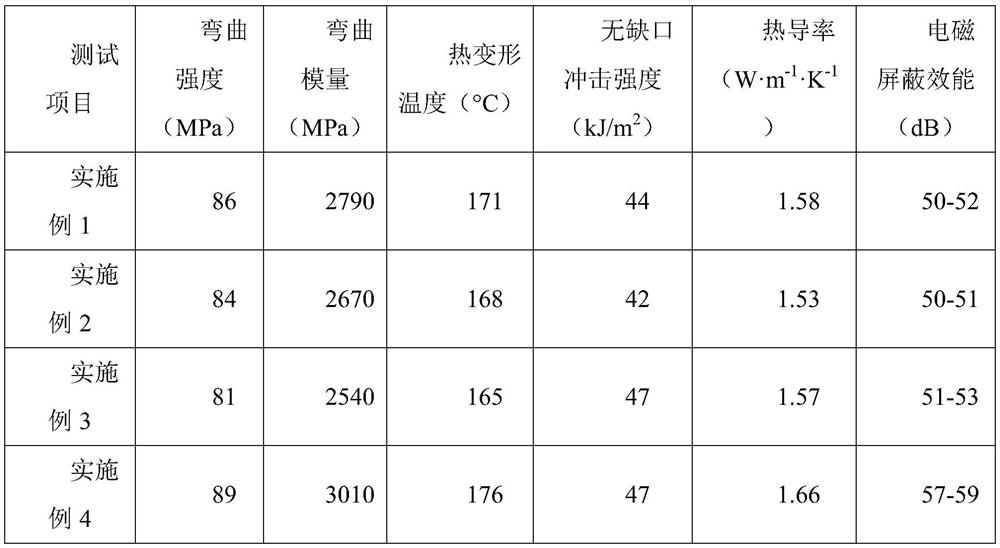

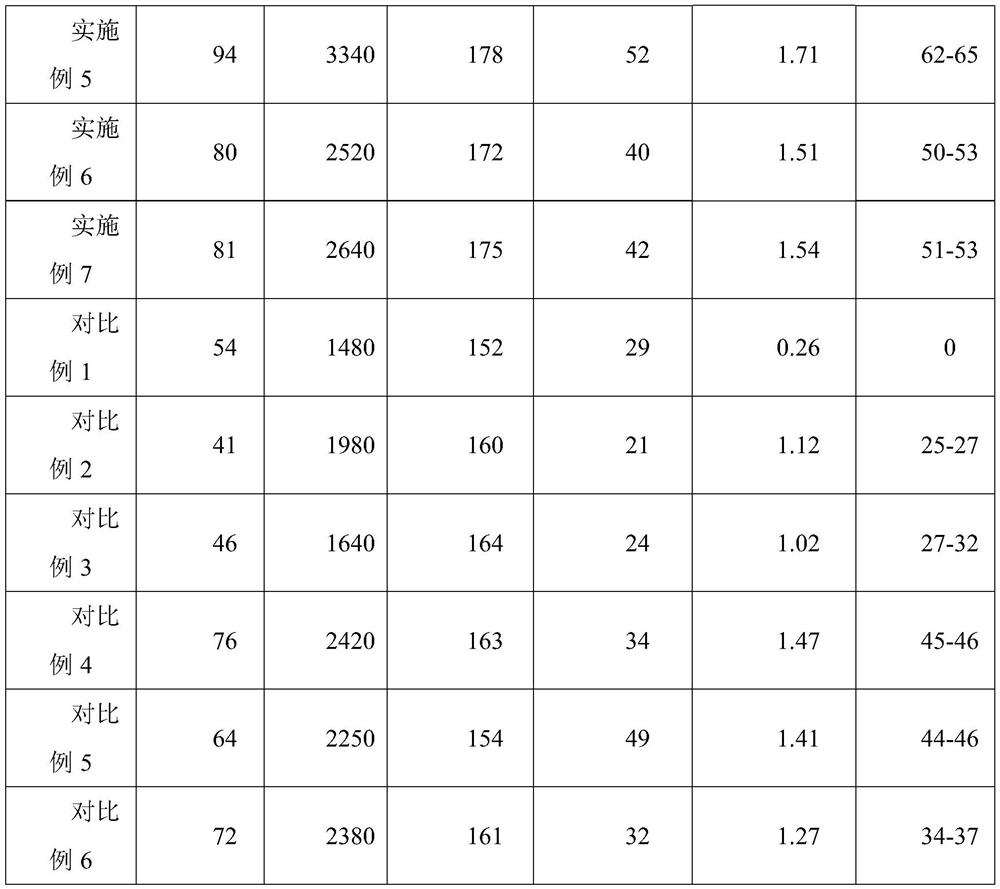

Examples

Embodiment 1

[0028] A high-strength electromagnetic shielding and heat-conducting PBT / PET nanocomposite material and a preparation method thereof, comprising the following components by weight: 70 parts of polybutylene terephthalate, 30 parts of polyethylene terephthalate Parts, 5 parts of glycidyl methacrylate grafted ethylene-octene copolymer, graphene-Fe 3 o 4Composite filler 5 parts, silane coupling agent KH560 0.5 part, antioxidant 10100.5 part, antioxidant 168 0.5 part.

[0029] The graphene-Fe 3 o 4 Composite filler, the specific preparation steps are as follows:

[0030] (1) the large-diameter graphene microsheets (thickness is 5-100nm, particle size D 50 90.0-130.0μm, number of layers > 10 layers), small diameter graphene microflakes (thickness 5-100nm, particle size D 50 10.0-14.0 μm, the number of layers > 10 layers) and sodium dodecylbenzenesulfonate are added to deionized water at a mass ratio of 2:1:3:350, ultrasonically dispersed for 3-5 hours to obtain a graphene dispe...

Embodiment 2

[0038] The method of the present embodiment is basically the same as the method of Example 1, the difference is that the addition of the polybutylene terephthalate is 80 parts, and the addition of the polyethylene terephthalate is 20 parts .

Embodiment 3

[0040] The method of this embodiment is basically the same as that of Example 1, except that the addition amount of the glycidyl methacrylate grafted ethylene-octene copolymer is 10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com