Broken road pipeline laying device

A pipeline laying and laying device technology, applied in pipeline laying and maintenance, mechanical equipment, transportation and packaging, etc., can solve the problems of slow project progress, labor-intensive, and large manpower consumption, and achieve high work efficiency and convenient laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

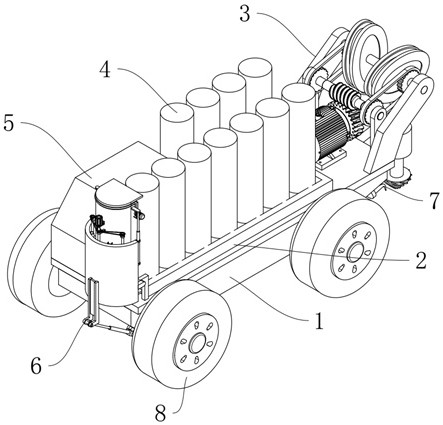

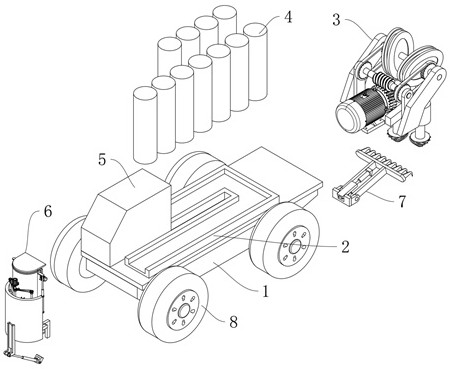

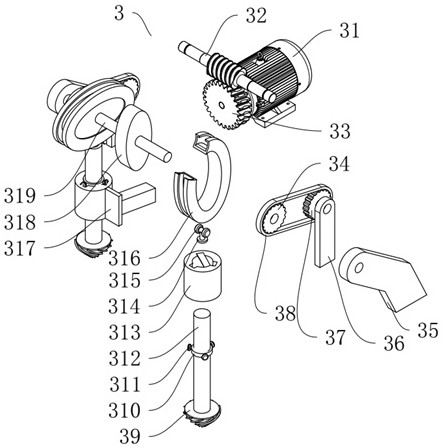

[0025] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 The shown road-breaking pipeline laying device includes a car body 1, a conveyor belt 2, a crushing device 3, a buried pipe 4, a driver's cab 5, a dumping and laying device 6, and a road surface breaking rake assembly 7.

[0026] The pulverizing device 3 includes: a beating motor 31; the dumping and laying device 6 includes: a swivel seat 612; the road surface destruction rake assembly 7 includes: a rake seat 71; A conveyor belt 2 is arranged near the center of the top of the car body 1. Several buried pipes 4 are placed inside the conveyor belt 2. Wheels 8 are arranged on the left and right sides of the car body 1 and near the front and back. Fixedly connected to the central position on the back of the top of the car body 1, two swivel seats 612 are fixedly connected to the front of the top of the car body 1 and near the right side, and the top of the rake seat 71 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com