A self-cleaning equipment for uniform heating of a coal-fired heat-conducting oil furnace

A heat-conducting oil furnace and uniform heating technology, which is applied to lighting and heating equipment, heat storage heaters, fluid heaters, etc., can solve the problems of low efficiency and manpower consumption, and achieve guaranteed efficiency, improved cleaning efficiency, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

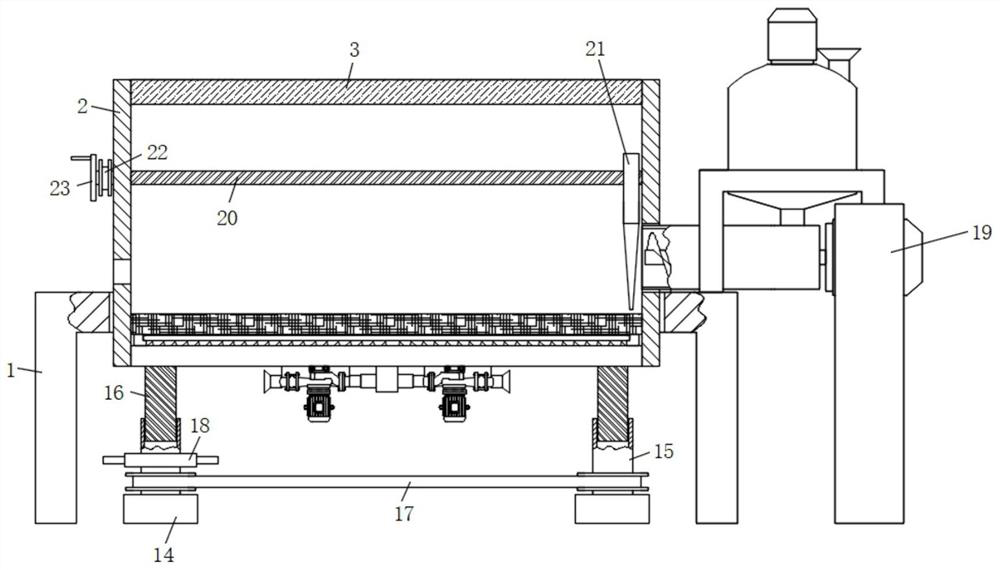

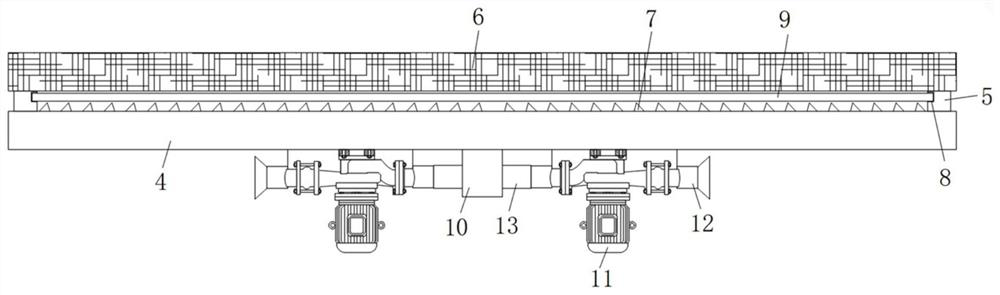

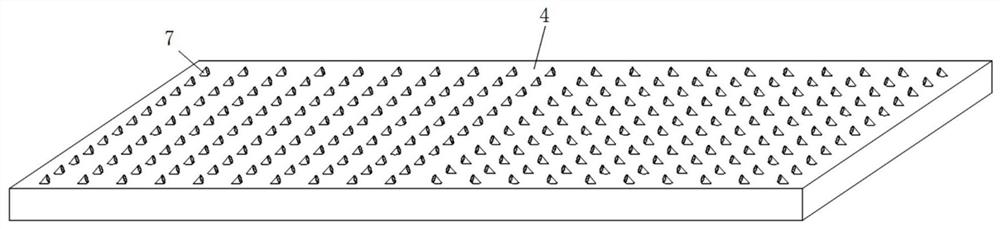

[0029] refer to Figure 1-5 , a self-cleaning equipment for uniform heating of a coal-fired heat-conducting oil furnace, including a mounting frame-1, a cylindrical hole is opened on the top surface of the mounting frame-1, the inner wall of the cylindrical hole is fixed with a heating chamber 2 through screws, and the inner wall of the heating chamber 2 is fixed on the top side A heat transfer plate 3 is connected, and a combustion assembly is arranged on the lower side of the inner wall of the heating chamber 2. The combustion assembly includes a hollow dish 4, and a support plate 5 is fixed on both sides of the top surface of the hollow dish 4 through screws, and a support plate 5 is fixed on the top of the support plate 5 through screws. The combustion net 6 and the top surface of the hollow dish 4 are also connected with an air injection pipe 7, and the two support plates 5 are provided with a chute 8 at one end close to each other. An air intake pipe 10 is connected, and...

Embodiment 2

[0032] Such as figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bulk material assembly 21 includes a mounting plate 211, and a threaded hole 212 is opened through the front and rear sides of the upper end of the mounting plate 211, and the screw rod 20 is screwed into the threaded hole 212. , the bottom surface of the mounting plate 211 is also fixedly connected with a dispersing rod 213 .

[0033] Multiple dispersing rods 213 are provided and evenly distributed on the bottom surface of the mounting plate 211 , and the front and rear sides of the mounting plate 211 are attached to the inner wall of the heating chamber 2 .

[0034] In this embodiment, by rotating the screw mandrel 20 to move a plurality of dispersing rods 213 in the heating chamber 2 to realize the dispersing operation of the coal, so that the coal can fully contact with the air, thereby ensuring the combustion rate of the coal.

Embodiment 3

[0036] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, an ignition port is provided at the lower end of the heating chamber 2 .

[0037] In this embodiment, an ignition port is provided at the lower end side of the heating chamber 2, so as to facilitate the ignition operation during combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com