Inspection robot for measuring pavement flatness and method

A technology for inspection robots and flatness, applied in the direction of measuring inclination, measuring devices, instruments, etc., can solve the problems of road surface data loss, small amount of data, and prone to large deviations, etc., achieve fast detection speed, reduce costs, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

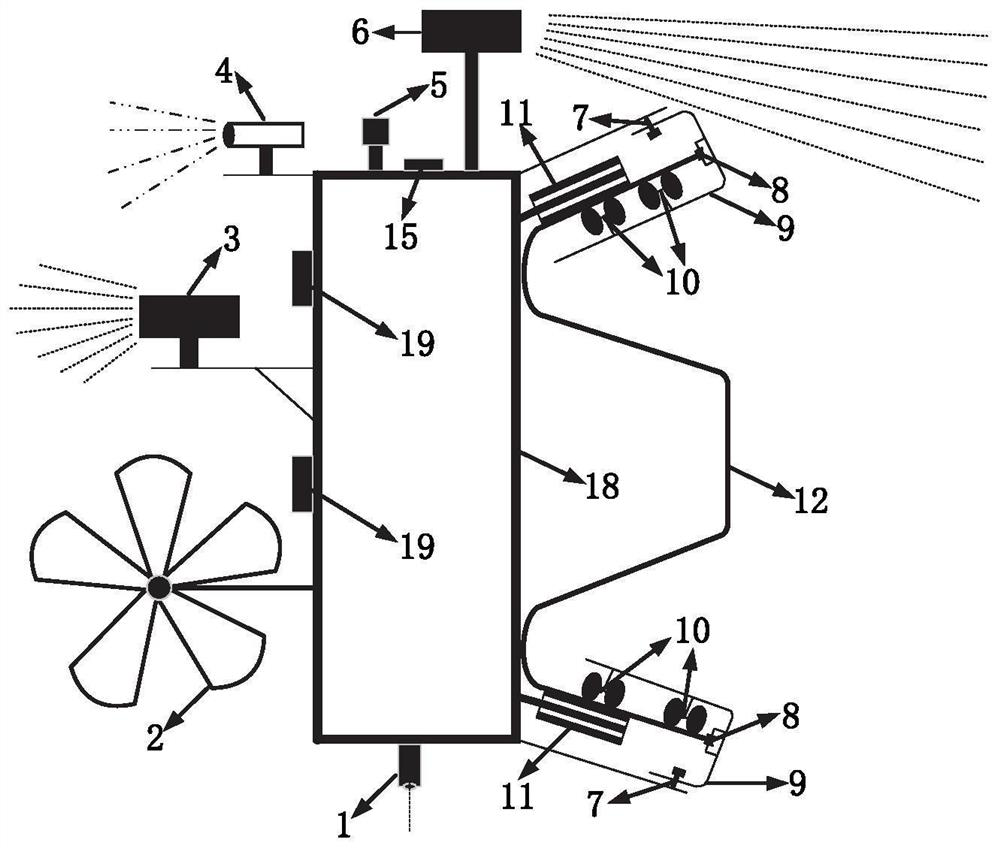

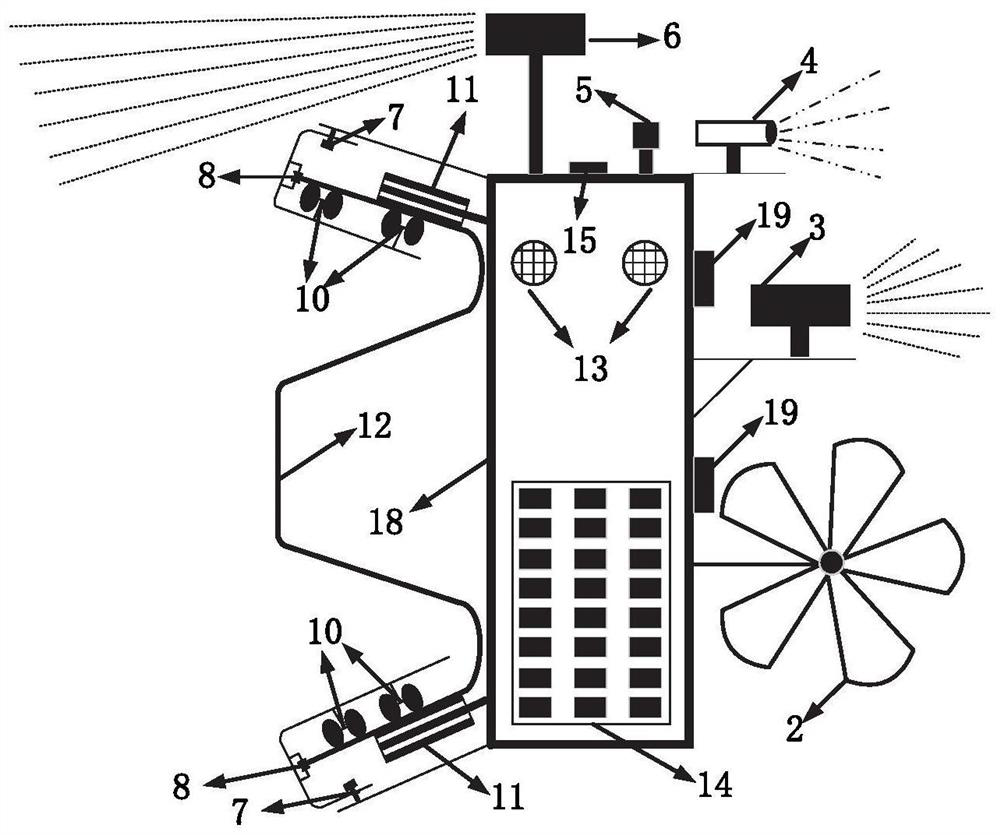

[0039] In one or more embodiments, an inspection robot for measuring road surface roughness is disclosed, referring to Figure 1-3 , including traveling devices, detection devices, fixing devices, power supply devices, early warning devices, positioning devices and warning devices.

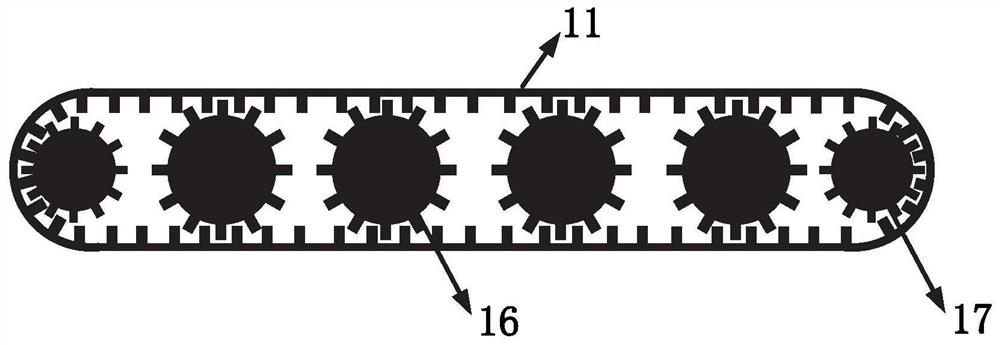

[0040] Such as figure 1 and figure 2 As shown, the fixing device is composed of an L-shaped fixed plate 9, a fixed plate directional wheel 8, and a fixed plate universal wheel 10. In order to link the L-shaped fixed plate 9 with the main body 18 of the inspection robot, the two are fixed by rivets 7 together. The L-shaped fixed plate 9 is anti-hooked on the upper and lower sides of the corrugated guardrail, and the L-shaped fixed plate 9 is respectively connected with the fixed plate directional wheel 8 and the fixed plate universal wheel 10;

[0041] The role of the fixed plate is exactly to fix the inspection robot on the guardrail; the role of the fixed plate directional wheel 8 is to drive...

Embodiment 2

[0056] In one or more embodiments, an inspection method of an inspection robot for measuring road surface smoothness is disclosed, including:

[0057] Trial run and calibration of various sensors on the inspection robot to ensure that it can work normally for a long time.

[0058] The inspection robot device is installed on the roadside wave guardrail 12 to ensure that the fixing device, the traveling device and the wave guardrail 12 are closely attached.

[0059] After the inspection robot collects data and completes the scheduled mileage collection work, extract the data for processing and analysis, complete road leveling and slope data collection, and road quality evaluation;

[0060] Specifically, control the inspection robot to move along the road guardrail;

[0061] Obtain road surface data in the form of surface units through the first multi-beam laser radar 3, and obtain the real coordinates of the data through coordinate conversion;

[0062] By calculating the mean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com