Self-heating drive circuit for AMOLED and heating method and device of self-heating drive circuit

A technology of driving circuit and heating method, which is applied in the field of circuit, can solve the problems of increasing pixel size and design complexity, etc., and achieve the effect of increasing external components and improving design complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

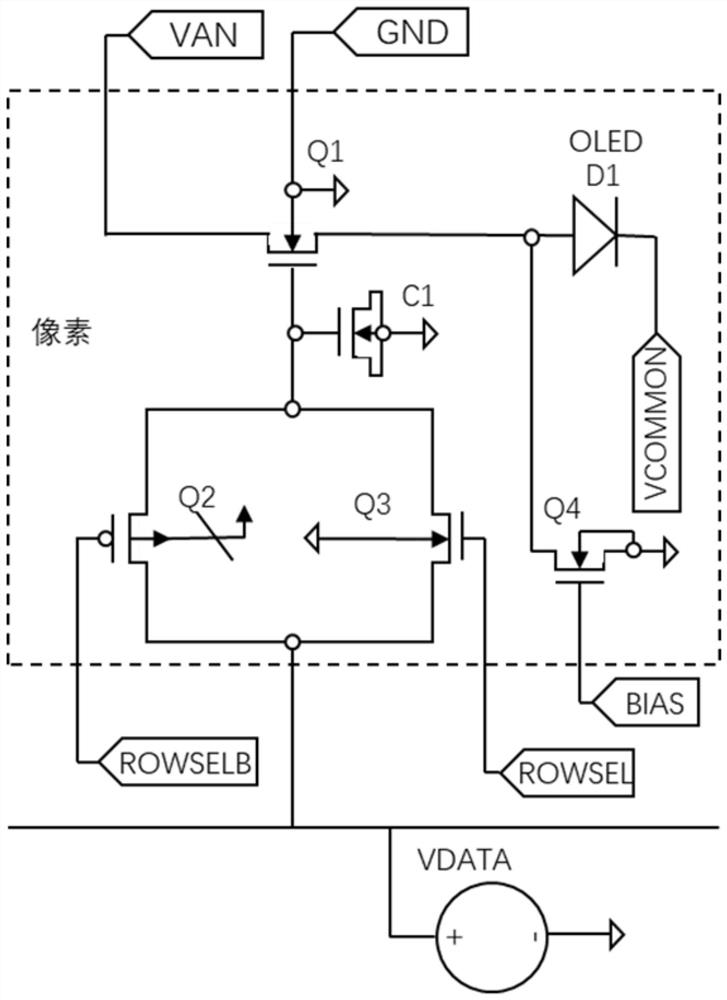

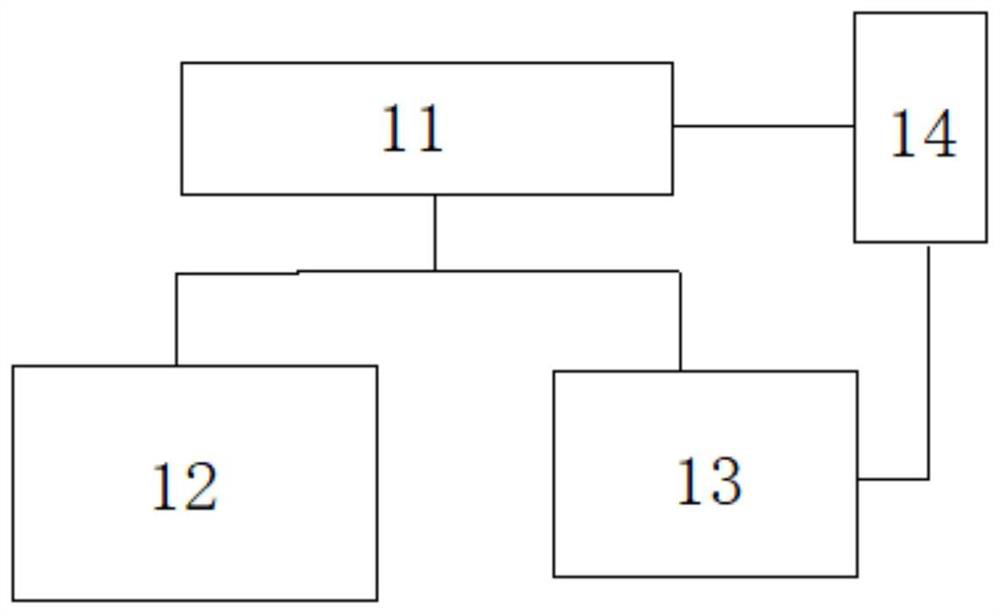

[0042] refer to Figure 1-2 As shown, a self-heating driving circuit for AMOLED includes: a light-emitting module 11 , a first driving module 12 , a second driving module 13 , and a temperature control module 14 .

[0043] The light-emitting module 11 includes an OLED light-emitting device D1, such as an OLED pixel, and each OLED pixel should contain at least three color sub-pixels.

[0044] In the present invention, the first driving module 12 is connected to the light-emitting module 11 and provides driving signals. Generally, the first driving module 12 includes a first transistor Q1 and a capacitor C1 arranged in parallel, and is set by the voltage of the first transistor Q1 The magnitude of the current in the light-emitting module 11, wherein the first transistor Q1 is preferably an NMOS transistor. In this example, the first driving module 12 also includes a transmission channel structure composed of a transistor Q2 and a transistor Q3 acting as a switch to form an acce...

Embodiment 2

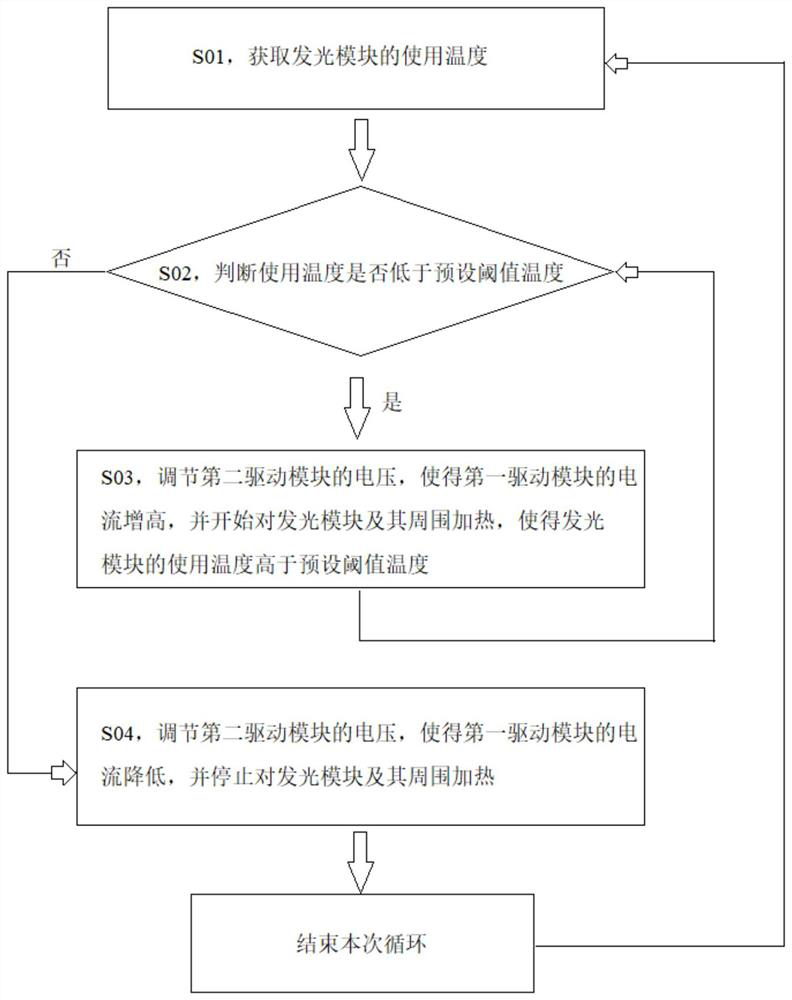

[0050] refer to image 3 As shown, the present invention also provides a heating method for AMOLED, comprising the following steps:

[0051] S01, obtaining the operating temperature of the light-emitting module;

[0052] S02, determine whether the use temperature is lower than the preset threshold temperature; if not, step S04; if so, enter step S03;

[0053] S03, adjust the voltage of the second driving module, so that the current of the first driving module increases, and start to heat the light-emitting module and its surroundings, so that the use temperature of the light-emitting module is higher than the preset threshold temperature, and return to step S02;

[0054] S04 , adjust the voltage of the second driving module to reduce the current of the first driving module, stop heating the light-emitting module and its surroundings, and end the current cycle.

[0055] Among them, the threshold temperature is between 10°C and -50°C. In order to achieve the best performance o...

Embodiment 3

[0060] A display device includes the self-heating driving circuit for AMOLED of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com