Tungsten filament fusing current control method

A fusing current and control method technology, applied in the field of electric power, can solve the problems affecting the detection sensitivity and detection consistency of the detection device, affecting the detection sensitivity, reducing the number of times of use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

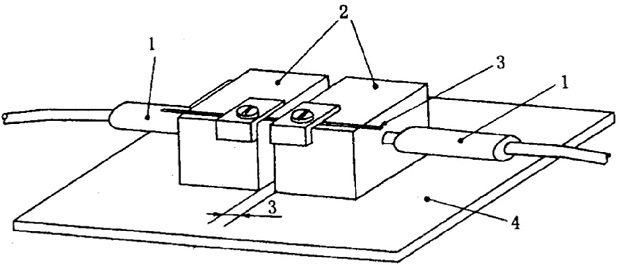

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0030] The invention relates to a control method for a tungsten wire fusing current, comprising the following steps:

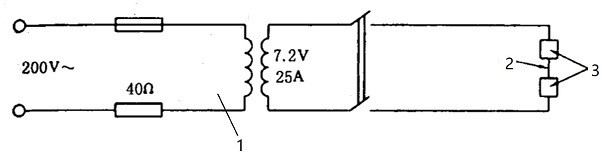

[0031] S1: Change the fusing power supply of the tungsten wire fuse device.

[0032] From the original power supply through a low-voltage high-current transformer, it is changed to a DC stabilized power supply 1 with an adjustable constant current source output. The output voltage DC of the DC stabilized power supply 1 is adjustable at 5-20V, and the output current range is adjustable at 9-40A. . Under the premise of output power 180W, adjust the output voltage and output current to adapt to different tungsten wire diameters.

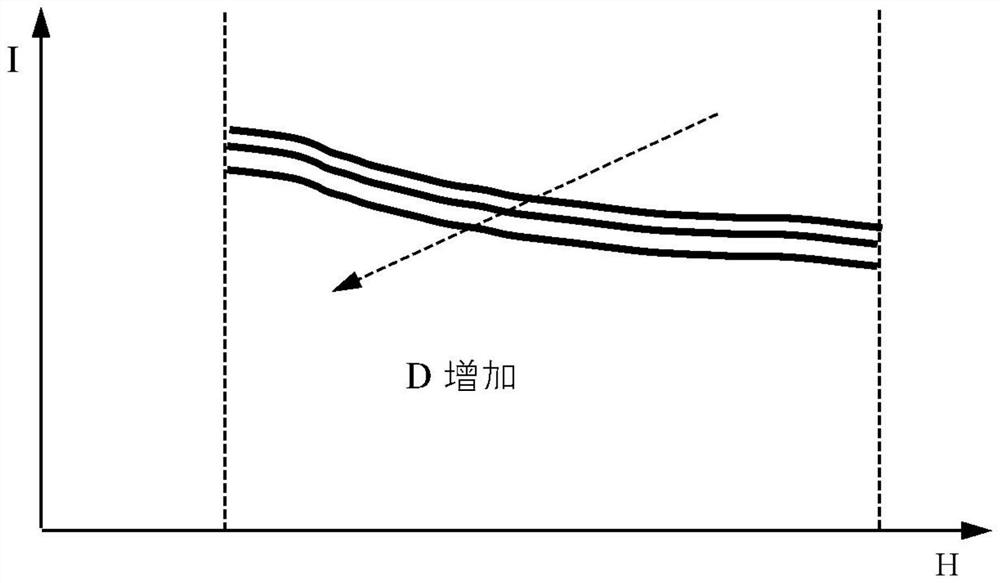

[0033] S2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap