Composite electricity testing grounding device and overhead line system electricity testing grounding control system

A grounding device and composite technology, applied in the field of rail transit, can solve problems such as high labor intensity, potential safety hazards, and restrictions on electric passenger cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

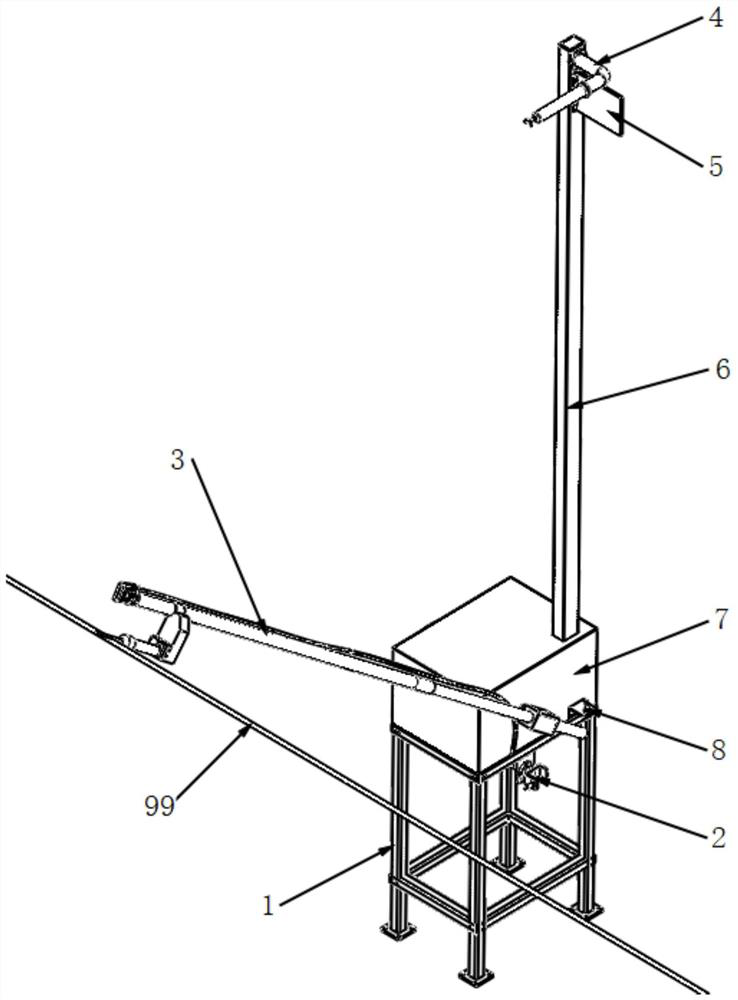

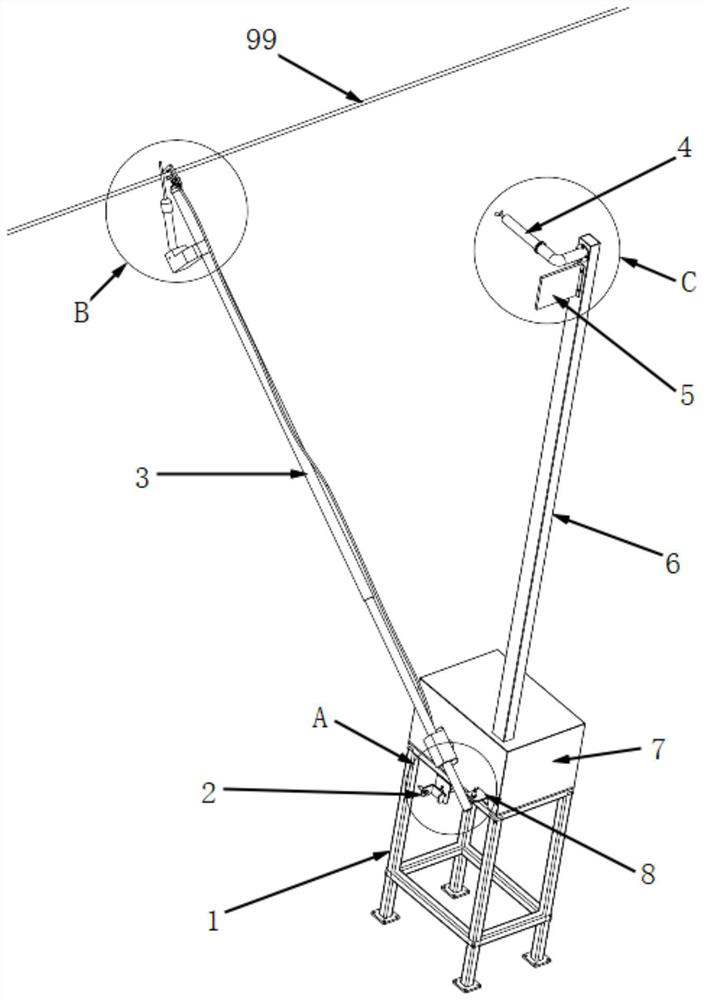

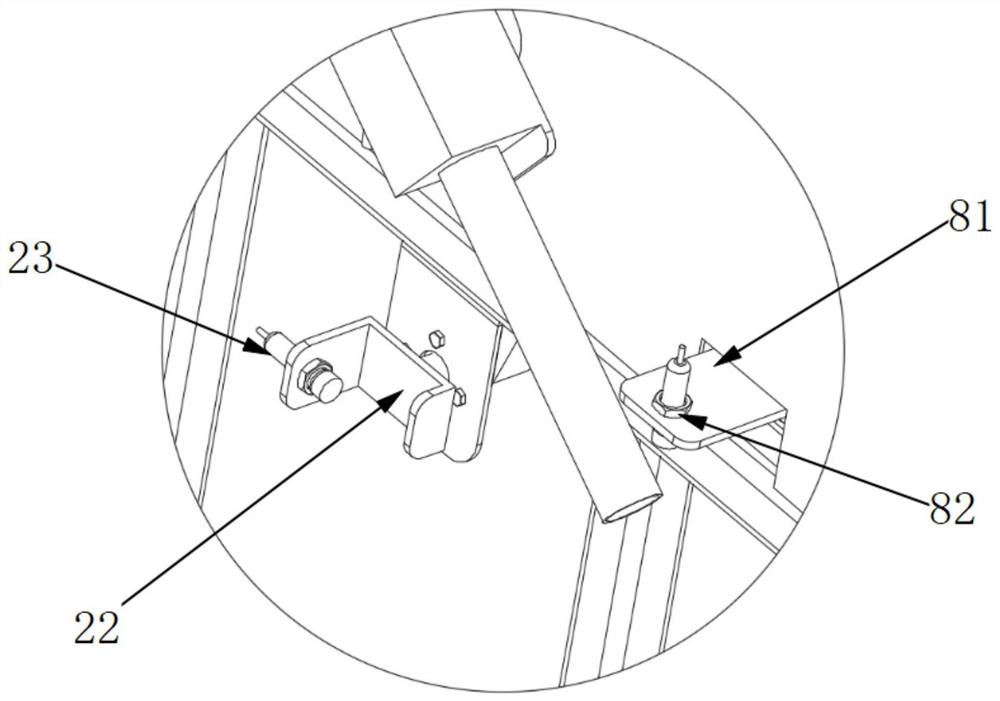

[0061] like Figure 1 to Figure 14 As shown, a composite electric test grounding device includes a mounting bracket 1, a driving device 7 fixed on the mounting bracket 1, and an electric testing ground rod assembly 3 connected to the output end of the driving device 7;

[0062] The electrical testing grounding rod assembly 3 includes a first insulating rod 32, a grounding knife 39 fixed on the first insulating rod 32, a detector 36 that is rotatably connected with the first insulating rod 32 and used for electrical testing, as a detector 36 metal rods 37 with metal heads;

[0063] The driving device 7 is connected to the rear end of the first insulating rod 32 and is used to drive the first insulating rod 32 to swing, and the rotating shaft forming the rotatable connection and the rotating shaft forming the swinging are parallel to each other;

[0064] The grounding knife 39 and the detector 36 are all arranged on the front end of the first insulating rod 32, and the metal ba...

Embodiment 2

[0072] like Figure 1 to Figure 14 As shown, this embodiment is further limited on the basis of Embodiment 1: as a technical solution to facilitate the reliable and insulated connection between the detector 36 and the first insulating rod 32, it is set as follows: the electric test grounding rod assembly 3 also includes a connecting block 34 and a second insulating rod 35, the connecting block 34 is fixed on the first insulating rod 32, the rear end of the second insulating rod 35 is rotatably connected to the connecting block 34, and the detector 36 The rear end is fixedly connected with the front end of the second insulating rod 35. In this solution, the second insulating rod 35 is used as an insulation isolation between the detector 36 and the first insulating rod 32, such as for isolating the detector 36 and the grounding wire 33, and the connecting block 34 can be a metal piece. To realize the reliable connection of two insulating rods.

[0073] Regarding the grounding ...

Embodiment 3

[0086] This embodiment is further limited on the basis of any one of the technical solutions provided by any one of the above embodiments, such as Figure 1 to Figure 14 As shown, in order to facilitate the realization of automation and intelligence or improve the level of automation and intelligence, this embodiment also discloses a catenary 99 electrical inspection and grounding control system, including the composite electrical inspection and grounding device described in any one of the above, Also includes:

[0087] Electric testing unit: connected with the detector 36, used for detecting the voltage value or voltage level on the catenary 99;

[0088] Detection unit: used for detecting the resistance value and charged state of the grounding wire 33 on the grounding knife 39;

[0089] Manipulation unit: used to realize the human-computer interaction with the compound electrometric grounding device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com