Synchronous control system and method based on repetitive motion multi-axis control

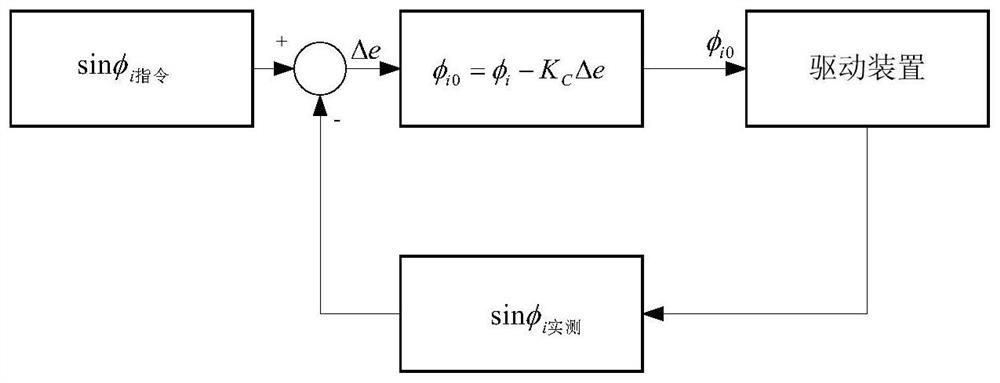

A multi-axis control and synchronous control technology, applied in the direction of speed adjustment of multiple motors, can solve the problems that it is difficult to ensure the smooth operation of the drive device, the constant deviation of the phase angle cannot be guaranteed, and the bionic device is difficult to realize, so as to achieve easy implementation and improvement Effect of phase difference and reduction of calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the above technical solution, the following detailed description will be understood by the drawings and the specific embodiments, and it is to be understood that the specific features of the present application and the embodiments in the present application are detailed descriptions of the present application. Not a limitation of the technical solution of the present application, in the case of unlipped, the technical features of the present application may be combined with each other.

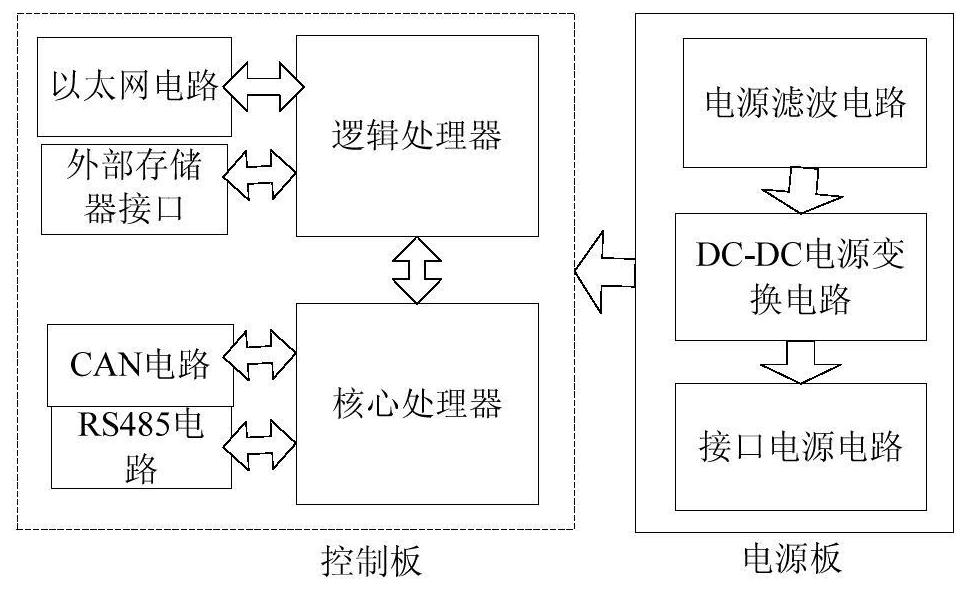

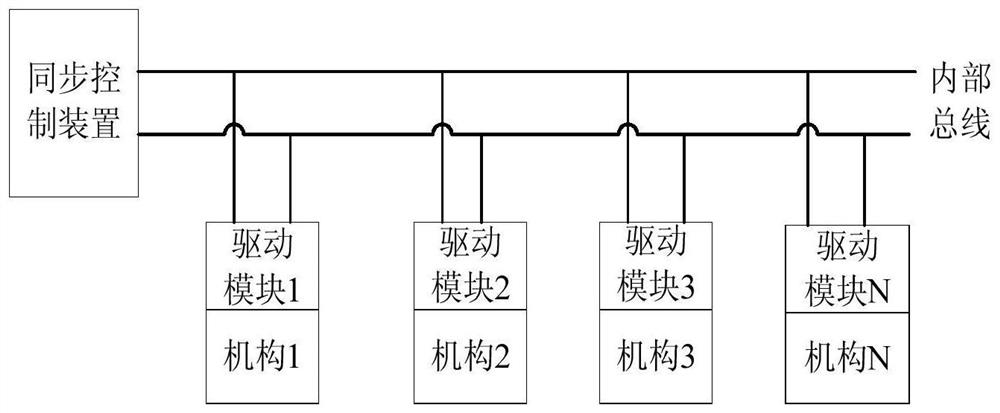

[0040] The following combination of the following combination of a synchronous control system and method provided by the repetitive motion multi-axis control will be described in further detail, and the specific implementation method can be included (eg, figure 1 Disted):

[0041] The synchronous control system consists of a synchronous control device and the corresponding drive module, the drive module completes the mechanism, the synchronization control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com