Automatic material distributing and mixing equipment for grinding tool machining

A technology of mixing equipment and grinding tools, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, slow feeding speed, and low work efficiency, and achieve improved mixing The effect of improving efficiency, increasing feeding speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

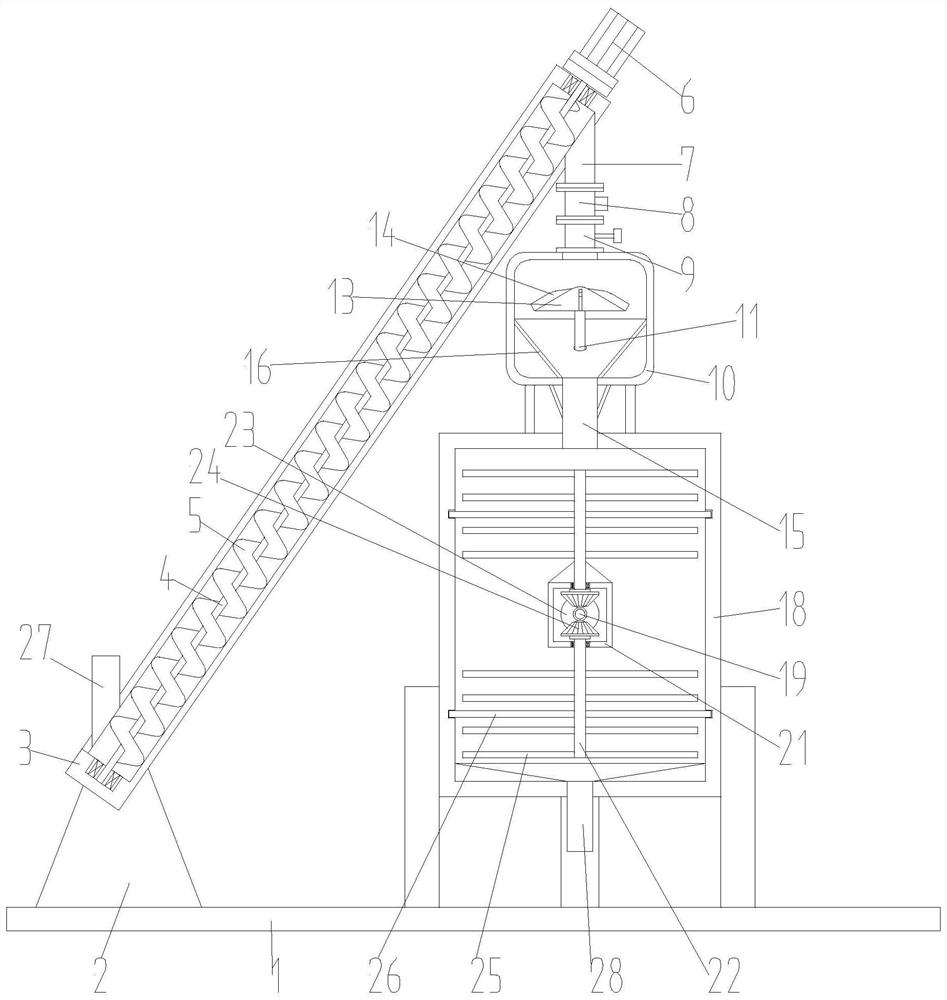

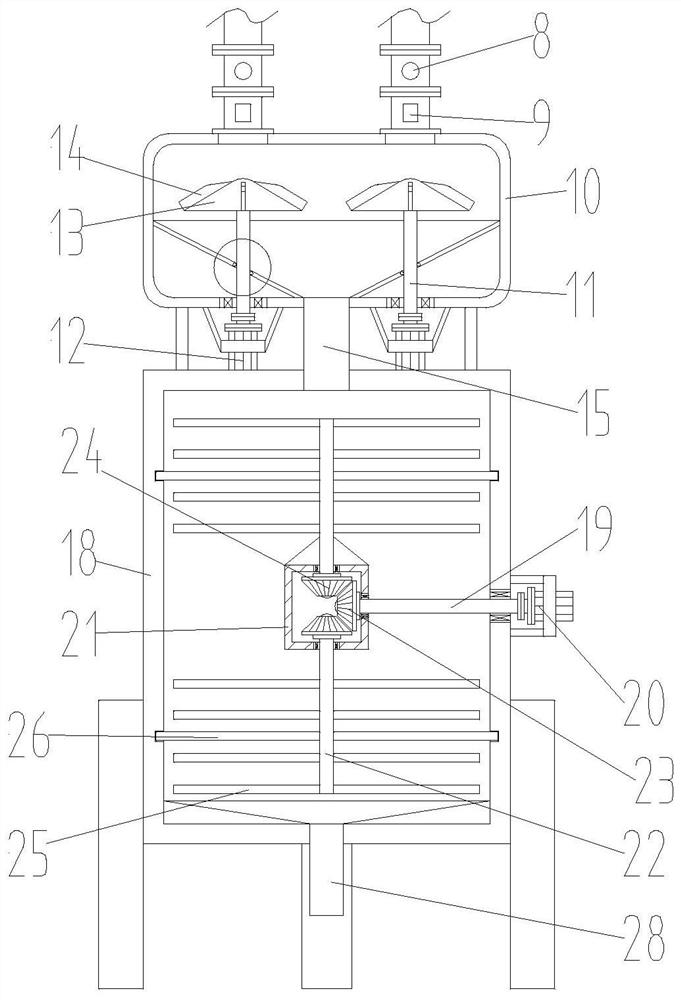

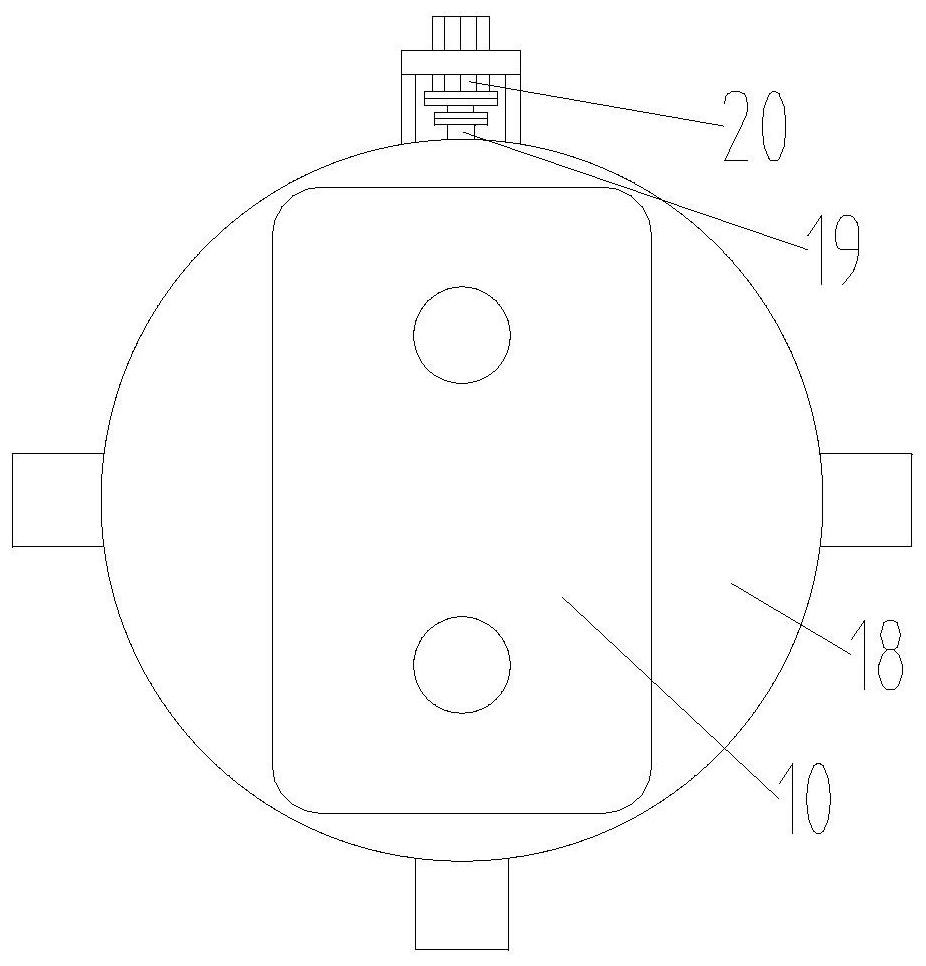

[0031] Embodiment: An automatic material distribution and mixing equipment for abrasive tool processing, including a base 1, a material distribution structure is provided on the base 1, a pre-mixing structure is provided at the lower end of the material distribution structure, and a material mixing structure is provided at the lower end of the pre-mixing structure;

[0032] In the specific implementation process, the material distribution structure can preferably adopt the following structure, which includes: two fixed seats 2, two feeding boxes 3, two first rotating shafts 4, two screw blades 5, two first motors 6 , two first outlets 7 and a switch part;

[0033] Two fixed bases 2 are installed on the upper wall of the base 1, two upper material boxes 3 are installed on the two fixed bases 2, two first rotating shafts 4 are inserted into the two upper material boxes 3, and two spiral blades 5 are installed On the two first rotating shafts 4, the two first motors 6 are install...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap