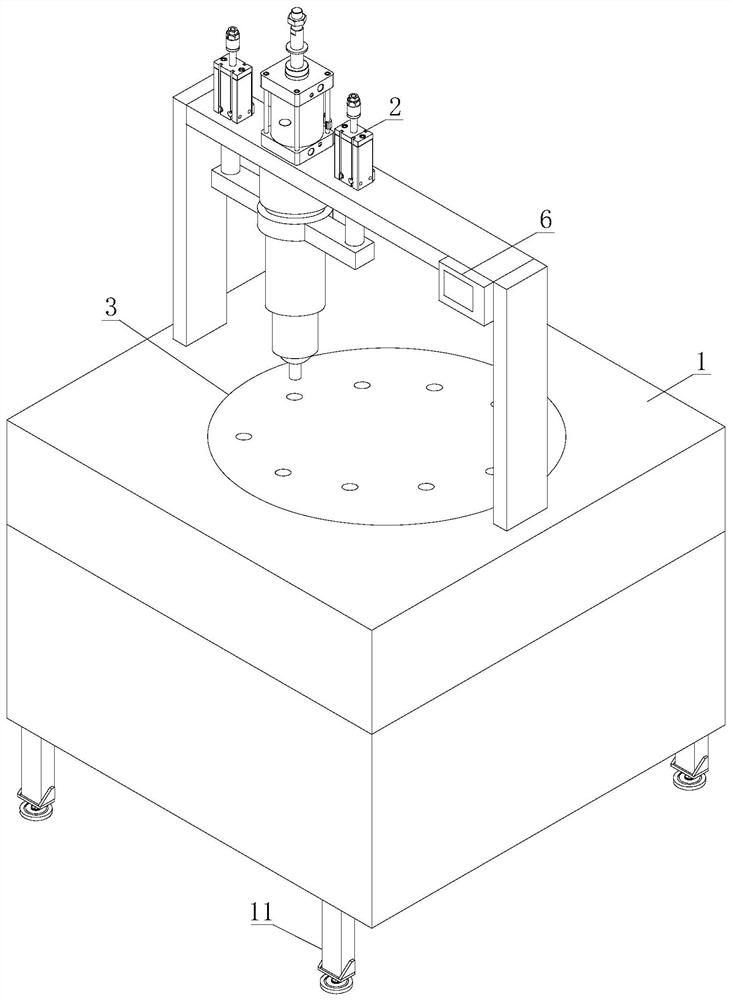

Injection molding machine capable of realizing multi-station simultaneous operation and implementation method thereof

An injection molding machine and multi-station technology, applied in the field of injection molding machines, can solve the problems of low production efficiency, high production cost, time investment, increase in manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] In order to better demonstrate the implementation process of an injection molding machine capable of multi-station simultaneous operation, this embodiment proposes an implementation method of an injection molding machine capable of multi-station simultaneous operation, including the following steps:

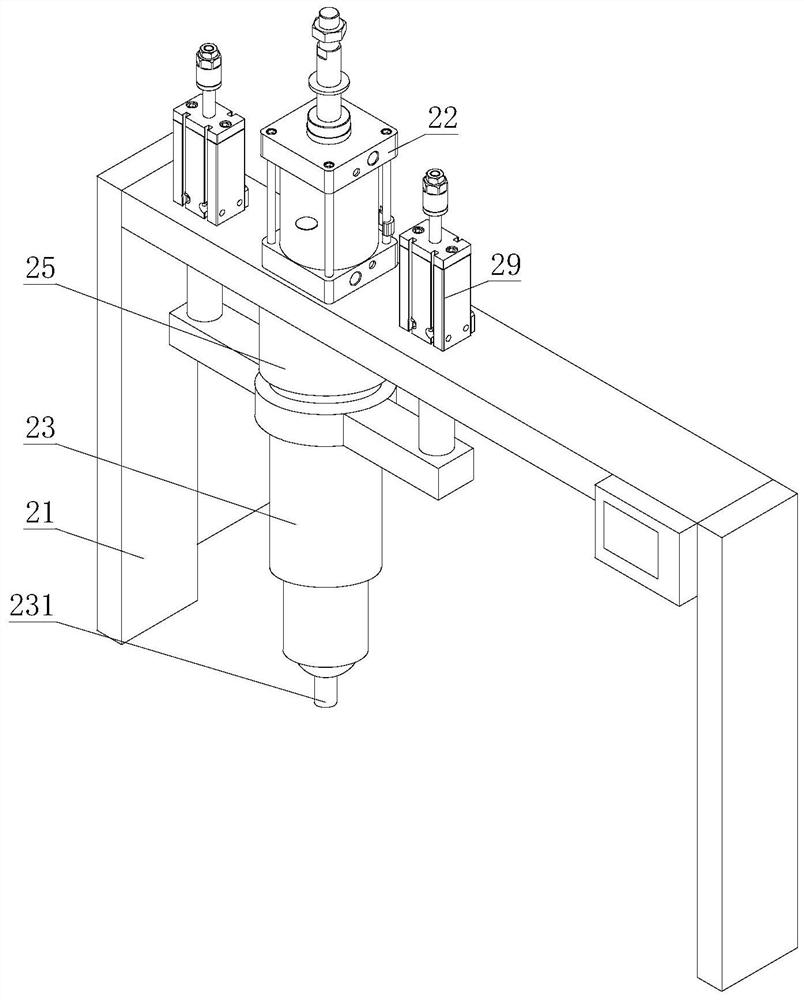

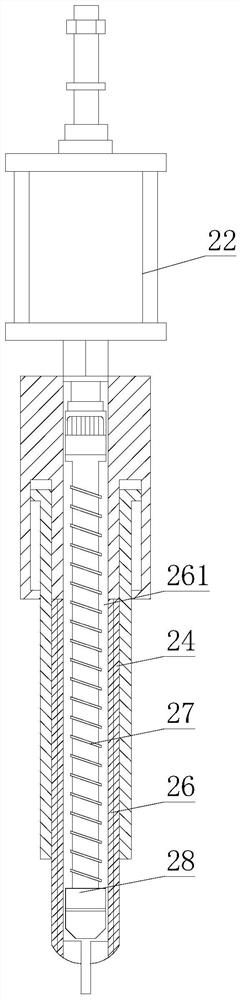

[0048] Step 1: The first upward moving cylinder 291 and the second upward moving cylinder 292 drive the injection nozzle 231 at the bottom of the outer sleeve 23 to connect with the injection port 32, and the injection motor 22 starts to drive the injection rod 27 and the piston head 28 in the injection cavity 261 Run, perform injection molding;

[0049] Step 2: Drive the multi-station molding assembly 3 to rotate through the station interleaving motor 41, thereby replacing the injection port 32 of different stations for injection molding, injecting plastic into the injection port 32, and finalizing the shape through the upper mold 33 and the lower mold 34;

[0050] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com