Controllable-stripping heat-sealing film for sterilizing and packaging medical instruments and preparation method of controllable-stripping heat-sealing film

A technology for medical devices and heat-sealing films, applied in household packaging, chemical instruments and methods, packaging, etc., can solve problems such as difficult quantitative control of peeling force, difficult quantitative design of peeling force, difficult precise control of peeling interface, etc., to achieve peeling The interface is controllable, the peeling force is controllable, and the peeling interface is clean and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the present invention, the present invention is illustrated below in conjunction with the accompanying drawings.

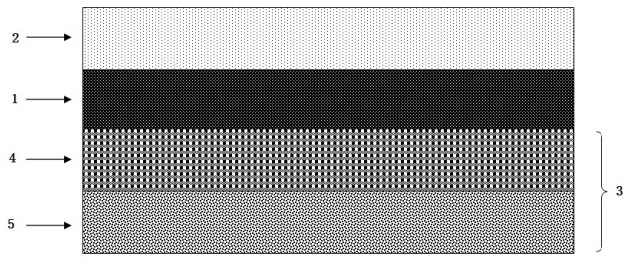

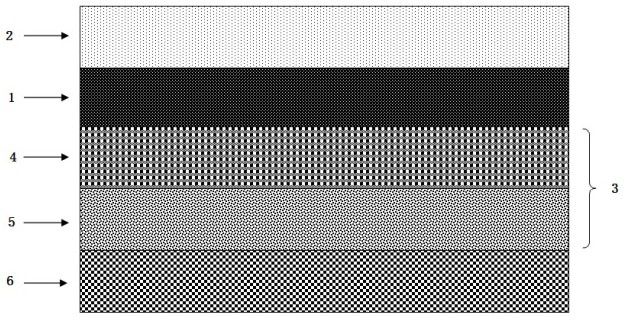

[0023] like figure 1As shown, a controllable peeling heat-sealing film for sterilization packaging of medical devices and preparation method thereof, the heat-sealing film can be heat-sealed with medical dialysis paper base paper or coated dialysis paper (6) to prepare paper-plastic bags , used for sterilization packaging of medical devices, the opening peeling force and opening interface of the paper-plastic bag are controllable, and the sealing integrity of the paper-plastic bag can be judged by the layer separation and color change on the film at the peeling place; its structure includes: : PET plastic base film (1), divided into two surfaces: front and back, the front is the printable surface (2); the back is the heat sealing layer (3), the heat sealing layer (3) is coated with The primer layer (4) on the PET plastic base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com