Water cup and manufacturing method thereof

A production method and water cup technology, which can be applied to drinking vessels, clay products, and other household appliances, can solve the problems affecting the cleanliness of the desktop and the use of water cups, and achieve the effects of strong interest, optimized structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

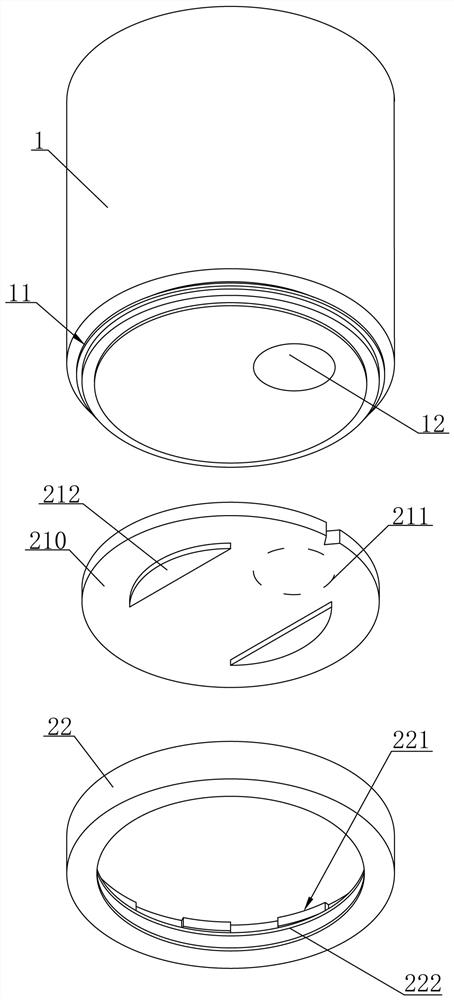

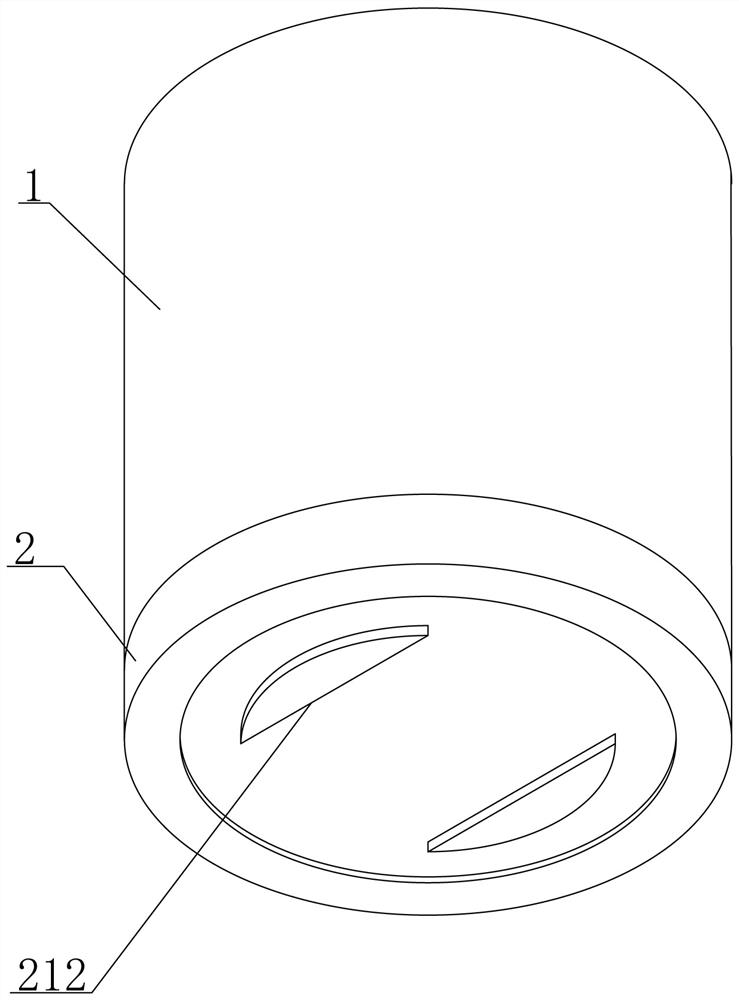

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0026] refer to figure 1 , figure 2 , a water cup and a manufacturing method thereof, comprising the following steps:

[0027] A water cup, comprising a cup body 1 and a base 2, the base 2 includes a base body and an assembly member 22, the base body is cylindrically arranged, the base body is rotatably assembled under the cup body 1, the top surface of the base body and the The bottom surface of the cup body 1 is arranged adjacent to each other. The fixed-axis rotatable assembly structure can be realized by a common structure, specifically, the assembly member 22 is assembled on the bottom of the cup body 1 through threaded connection, that is, the cup body 1 is provided with an external thread member 11 along the bottom along the circumferential side, and the assembly member 22 The inner thread member 221 on the upper part thereof is assembled to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com